Have you ever seen a drill cut through hard rock like it's nothing? DTH hammers do this. It's really amazing. DTH hammers are the secret.

DTH hammers are strong drilling tools. They use compressed air to power a piston. This piston hits the drill bit very fast, allowing it to easily break through hard rock. This method saves energy.

I remember standing on a construction site. The rhythmic pounding of a drill echoed through the air. Watching the DTH hammer cut through stubborn rock amazed me. It moved through layers with ease. Understanding how they work is important. These devices are very special. They drill quickly and use less energy. They have advantages over other methods. Learning about these aspects is really eye-opening. Professionals love DTH hammers for many drilling tasks.

DTH hammers use hydraulic fluid for operation.False

DTH hammers operate using compressed air, not hydraulic fluid.

DTH hammers are more efficient at greater depths than top hammer drills.True

They maintain power over extended drill string lengths, unlike top hammer drills.

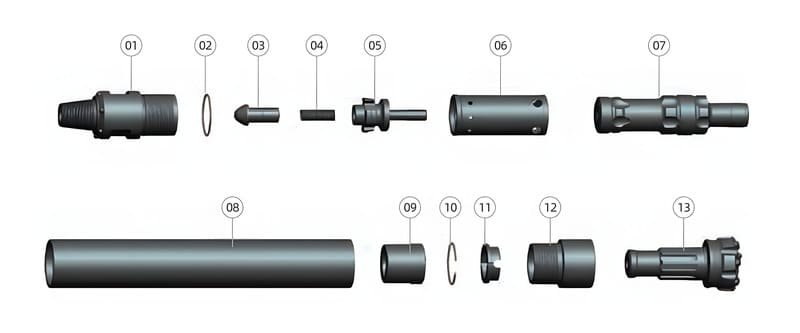

What are the Key Components of a DTH Hammer?

Imagine uncovering the secrets of a DTH hammer and finding out what gives it such strength. It's fascinating.

A DTH hammer consists of a piston, drill bit, chuck, hammer casing and drive sub. Each part connects to deliver powerful hits to the drill bit. These strong impacts help the drill bit cut through rock layers easily. Rock layers break efficiently.

The Piston: Heart of the Hammer

I recall the first moment I observed a DTH hammer at work; it was like witnessing a smooth dance between man and machine. The piston sits at its center, moving tirelessly back and forth, powered by compressed air1. This small powerhouse creates those fast strikes that break through rocks. It felt like watching my grandfather crack walnuts with skill. Every strike was precise. This was very intentional. No effort was wasted. When selecting a DTH hammer, look for pistons made from high-quality materials for long-lasting use.

Drill Bit: Cutting Edge Tool

The drill bit is where everything really happens. Like choosing the right knife to cut tough meat, selecting the right drill bit changes everything. These are made from tungsten carbide2. They handle different rock types and drilling tasks. The speed and accuracy of your drilling often rely on this tool, much like finding the exact tool for any task.

Chuck: The Firm Holder

The chuck acts like a strong handshake that holds everything together. It grips the drill bit tightly, tolerating immense pressure, much like my reliable hiking boots that endured rough terrains. Built with durable materials such as heat-treated steel, it is essential for ensuring accuracy during drilling. A worn chuck feels like a shaky wheel; operations just don’t go well.

Hammer Casing: Guarding Shell

The casing surrounds these vital elements like a protective shield. It defends them from harsh conditions, keeping everything aligned and working efficiently. The design also affects airflow inside the hammer. Choosing a casing with very good corrosion resistance matters, especially when working in tough environments.

Drive Sub: Connecting Element

Finally, there’s the drive sub - it’s the modest hero linking the hammer to the drill string. Like a reliable bridge, it transfers rotational force and air pressure crucial for smooth operations. Regular checks on this part can stop problems like misalignment or air leaks which might halt your work.

For those interested in exploring further about different types of DTH hammers3 and their uses, learning about specific brands or models might reveal advanced technologies and features that really suit your next project.

DTH hammers use hydraulic power for operation.False

DTH hammers operate using compressed air, not hydraulic power.

DTH hammers are efficient in hard rock formations.True

They deliver high-frequency impacts that enhance drilling speed.

How Does Compressed Air Power a DTH Hammer?

Have you ever thought about how a basic tool like a DTH hammer slices through hard rock easily?

Compressed air moves a piston inside a DTH hammer. This action creates a strong force to break rock efficiently. The air flows through the drill string, changing pressure. This pressure pushes the piston quickly. Energy travels straight to the drill bit.

The Role of Compressed Air in DTH Hammers

I am truly amazed by the power of air. Imagine air from your lungs moving a jackhammer! In drilling, compressed air is like a secret ingredient that powers everything. It pushes the piston inside the hammer so fast and strong that rocks easily break apart. Air moves through the drill string to the hammer, right above the drill bit. It's like a powerful boxer hitting the target directly without losing any energy loss4.

Mechanism and Benefits

A DTH hammer is like a drummer, not making music but opening paths in the earth. Air pressure moves the piston quickly back and forth, hitting the drill bit many times. This creates a strong force that easily breaks rocks. The first time I saw this, it was like watching an expert at work, each strike precise and strong.

This tool doesn't just break rock fast; it maintains high penetration rates5 even when digging deep. I find it very helpful for tough projects where other methods might slow down. It is also very versatile, working well for vertical, horizontal, and angled drilling. It adapts easily.

Technical Insights and Applications

In places like mines or geothermal sites, conditions are usually tough. Here, compressed air shows its full strength in DTH hammers. On site, I need tools that truly work well and consistently. Knowing how these tools function lets me choose the right compressors and fix issues before they grow.

Understanding how air powers a DTH hammer is not just knowledge; it's key to keeping work productive. This awareness helps me stop small problems early, keeping operations smooth and avoiding costly breaks.

DTH hammers use hydraulic fluid for operation.False

DTH hammers operate using compressed air, not hydraulic fluid.

DTH hammers are effective in deep hole drilling.True

They maintain power at greater depths, unlike top hammer drills.

Why Are DTH Hammers Perfect for Deep Hole Drilling?

Have you ever wondered why DTH hammers are the top choice for deep hole drilling? Let's explore their really impressive features.

DTH hammers are great for drilling deep holes. They drill really fast. They use energy well and work well at great depths. The hammers sit near the drill bit. This position gives them very strong power and high efficiency. They are perfect for many drilling jobs.

Core Functionality of DTH Hammers

DTH hammers focus on being fast and exact. They operate using a piston-driven mechanism powered by compressed air, which strikes the drill bit with rapid, powerful blows. This sends energy directly to the rock, speeding up the drilling process significantly.

High Penetration Rates

Think about drilling through tough granite. DTH hammers are great for that due to their ability to deliver high-frequency impacts. They hit fast and hard in difficult rocks, enhancing drilling speed and efficiency. I’ve watched projects finish in hours, not days, thanks to these tools.

Deep Hole Drilling Capability

DTH hammers reach deep places like no other tools. Unlike top hammer drills that can't maintain strength far down, DTH hammers stay strong and consistent in performance over long distances. I once worked on a job that needed drilling very deep; DTH hammers handled it easily.

Reduced Energy Loss

DTH hammers work close to the drill bit, minimizing energy loss by positioning the hammer mechanism near the impact point. This smart design helps save energy as it's like putting a strong engine exactly where it’s needed. Other methods lose power because their source is far away.

Versatility in Drilling Applications

DTH hammers are very flexible across various scenarios - vertical, horizontal or angled drilling. They suit all types of projects whether in quiet places or busy cities. Their capacity to handle urban environments6 where noise and vibration control are essential adds to their appeal.

Considerations for Equipment Selection

You must pick the right tool for deep drilling needs. DTH hammers work best over long distances without losing power and are reliable in tough rock formations requiring precise control. They never disappoint when you need a trusted helper for drilling.

DTH hammers use hydraulic fluid for operation.False

DTH hammers operate using compressed air, not hydraulic fluid.

DTH hammers are effective for deep hole drilling.True

They maintain power over long drill strings, enhancing depth efficiency.

What Makes DTH Hammers Stand Out Among Drilling Techniques?

Do you ever think about how DTH hammers compare to other drilling methods? Let's explore their advantages and disadvantages.

DTH hammers provide fast drilling and work well in hard rocks. Their structure helps them use energy effectively. This happens because the hammer acts right near the drill bit. They are useful for different drilling tasks. However, using them might cost more than other methods. These tools are powerful and efficient.

Main Benefits of DTH Hammers

I recall my first project with a DTH hammer. The speed was amazing. It felt like a machine working perfectly. These hammers hit hard and fast, making them very good at drilling quickly through tough rocks. They work with a mechanism close to the drill bit, ensuring that energy is not wasted—an efficiency similar to what is described in drilling speed7 resources.

Efficiency and Depth Comparison

DTH hammers perform well at deep levels, maintaining strength even as they go deeper. Unlike top hammer drills, which lose power over long distances, DTH hammers adapt well to various drilling angles. This flexibility makes them very useful for many tasks requiring deep penetration into the earth.

Cost and Use Factors

These hammers are not cheap due to the need for compressed air systems and special gear, leading to higher initial setup costs—similar to investing in quality kitchen tools. However, like these tools, they save time later by reducing breaks and delays in work—a crucial factor when time is short as highlighted in operational costs8.

Comparing with Other Drills

In hard rock environments, DTH hammers outperform rotary drills, which are more suited for softer grounds lacking the necessary power for hard materials. Top hammer drills are ideal for short tasks due to their lower cost and simpler operation but suffer from energy loss over longer distances.

Understanding these differences helps me pick the right tool—a choice that's really important on the job. For more insights into these methods and their applications, exploring resources on drilling techniques9 can provide further guidance.

DTH hammers lose power over long drill strings.False

DTH hammers maintain power at depth, unlike top hammer drills.

DTH hammers are less versatile than other drilling methods.False

DTH hammers offer versatility for vertical, horizontal, and angle drilling.

What Applications Benefit Most from Using DTH Hammers?

Have you ever thought about how certain drilling projects handle difficult grounds so easily? The secret is DTH hammers.

DTH hammers revolutionize mining, construction and geothermal drilling. They provide fast penetration, deep hole drilling and save energy. These tools increase productivity and precision. Hard rock formations pose no challenge to them. Deep drilling tasks benefit from their performance.

Mining and Quarrying

I first saw a DTH hammer at a mining site. It worked like a perfectly tuned machine, cutting through rock easily. These hammers are crucial in mining and quarrying for their ability to handle hard rocks with great efficiency. Their deep drilling helps reach valuable minerals fast, leading to fewer delays and lower costs. The high penetration rates10 ensure operations can proceed quickly.

Construction Projects

I once worked on a construction project with drilling challenges. DTH hammers solved these problems due to their versatility in adapting to various ground types. Whether vertical, horizontal, or angled, they manage them all efficiently. They are like Swiss Army knives for foundation piling and infrastructure work, ready for every challenge.

Geothermal Energy Drilling

I care about sustainable energy, and DTH hammers play a significant role in geothermal drilling by reaching geothermal reservoirs efficiently. Their efficient energy transfer keeps performance steady, which is vital for tapping into clean energy sources.

Water Well Drilling

I recall when drilling water wells was tough due to varying rock layers. DTH hammers changed this by breaking through hard formations effectively to find aquifers. This capability is crucial in areas with solid rocks where traditional methods struggle.

Oil and Gas Exploration

Accuracy and depth matter significantly in oil and gas exploration. DTH hammers provide the needed power and precision to navigate complex geological structures reliably under demanding conditions.

For those interested in learning more about DTH hammer advantages11 and other drilling technologies, examining these insights probably helps choose the right one for projects.

DTH hammers use hydraulic fluid for operation.False

DTH hammers operate using compressed air, not hydraulic fluid.

DTH hammers are efficient in deep hole drilling.True

They maintain power at greater depths, unlike top hammer drills.

Conclusion

DTH hammers are powerful drilling tools that use compressed air to drive a piston, delivering rapid impacts for efficient rock penetration, especially in deep hole drilling and tough formations.

-

Learn how compressed air drives DTH hammer pistons efficiently. ↩

-

Explore why tungsten carbide is preferred for drill bits. ↩

-

Discover various DTH hammer types for diverse drilling needs. ↩

-

Explore how energy loss impacts drilling efficiency. ↩

-

Understand why high penetration rates are beneficial. ↩

-

Learn how DTH hammers minimize noise and vibration in urban settings. ↩

-

Explore how DTH hammers outperform others in speed and efficiency. ↩

-

Understand the cost implications of choosing DTH hammers. ↩

-

Gain insights into various drilling techniques and their applications. ↩

-

Learn about efficiency improvements in mining with high penetration rates. ↩

-

Understand why DTH hammers are preferred for challenging drilling tasks. ↩