Picture yourself during an important drilling job. Suddenly, your tools stop working.

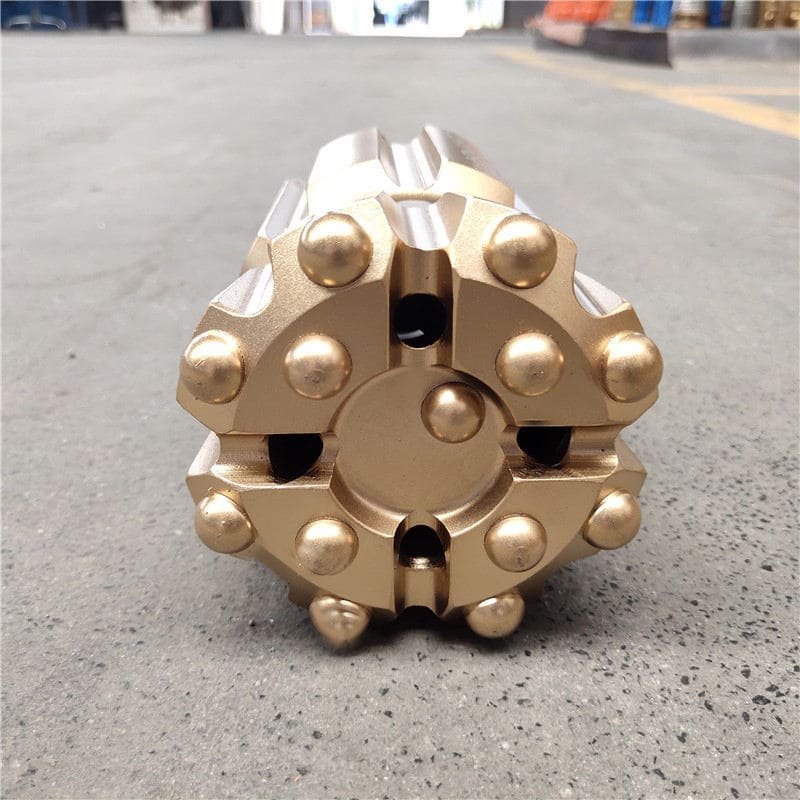

The split skirt problem in DTH button bits occurs mainly from misalignment. Improper feed pressure also leads to this issue. Excessive torque is another reason. Material fatigue very often plays a role. These causes create cracks or splits in the bit's skirt. Cracks in the skirt affect the bit's performance. Performance suffers greatly.

Understanding the root causes is only the beginning. I recall when we experienced downtime due to a similar problem. Misalignment caused this issue. We fixed our setup and focused more on adjusting the pressure. As a result, we greatly reduced failures. Now, let’s explore how these factors work. Let's find ways to stop such expensive problems.

Misalignment during drilling causes split skirt condition.True

Misalignment leads to uneven stress distribution, causing splits.

Material fatigue has no effect on DTH button bits.False

Material fatigue weakens the bit, leading to cracks and splits.

How Does Misalignment Affect DTH Button Bits?

Do you ever think about why some drilling projects encounter surprising problems?

Misalignment in DTH button bits causes uneven stress distribution. This leads to early wear and structural damage. Drilling efficiency also gets reduced. Proper alignment of these bits is very important. Proper alignment helps them work optimally and last longer.

Understanding Misalignment in Drilling Operations

I remember a very tense day when everything seemed perfect on paper, but the drill just wouldn't behave. Misalignment appears when the drilling path of the DTH button bit1 strays off course. This happens due to hasty rig setups or unpredictable geological changes. Realizing how these shifts disturb both performance and lifespan was a hard lesson learned.

Effects of Misalignment on DTH Button Bits

1. Uneven Wear and Tear

Picture hitting a rock with a hammer that only strikes one side. The same thing happens when a DTH button bit is misaligned. It leads to uneven force distribution across the bit's surface, causing:

- Premature Button Wear: I once noticed buttons wearing faster on one side. It was like wearing down just one shoe in a pair.

- Increased Friction: Uneven contact increases friction, generating heat and causing more wear.

2. Structural Damage

Misalignment puts too much pressure on specific areas of the bit, similar to applying pressure only on one table corner. Stress points become cracks or splits, especially under high torque or pressure settings, as seen in the split skirt condition2.

Identifying Misalignment Causes

Here is a summary of potential problems:

| Cause | Description |

|---|---|

| Hole Deviation | Geological variations causing the drill path to deviate. |

| Rig Setup Issues | Improper alignment during setup leading to initial misalignment. |

| Worn Equipment | Worn out components like retaining rings leading to instability. |

Learning about these issues early probably saves lots of trouble and creates better solutions.

Mitigating Misalignment Risks

- Regular Equipment Checks: Like checking car tires for wear, ensuring components such as retaining rings are in good shape prevents instability.

- Proper Setup Procedures: Following setup guidelines is very important to avoid initial misalignment problems.

- Monitoring Systems: Using real-time monitoring is like having an alert friend; they warn you of deviations early and allow timely corrections.

Addressing these aspects not only improves drilling efficiency3 but also extends equipment life. These methods really helped me sleep better at night, knowing my operations run smoothly.

Misalignment causes uneven wear on DTH button bits.True

Misalignment leads to uneven force distribution, causing premature wear.

Proper rig setup eliminates all misalignment issues.False

Geological variations can still cause misalignment despite proper setup.

How Does Feed Pressure Affect Bit Integrity?

Some drilling bits last longer than others. The secret often hides in the feed pressure during drilling.

Feed pressure is very important for bit strength. It helps the drill bit stay in good contact with the rock surface. Good pressure avoids too much wear and cracking. This probably extends the bit's lifespan.

The Importance of Feed Pressure

In the drilling industry, feed pressure is very important. It is like the Goldilocks of drilling - too little pressure and nothing sticks; too much pressure and everything breaks. Proper pressure lets drill bits grip the rock correctly. This allows energy to transfer efficiently and reduces wear. It's the difference between a productive day and one with equipment breakdowns.

Effects of Incorrect Feed Pressure

-

Insufficient Pressure: My drill bit danced on the rock instead of cutting it. Without enough pressure, the bit skids over the rock surface, increasing wear and risking early breakdown4.

-

Excessive Pressure: Another time, I used too much pressure. It was like watching a slow-motion disaster. The bit's structure weakened, leading to "split skirt" conditions, especially common with DTH button bits.

Balancing Feed Pressure

Balancing feed pressure is like making a perfect espresso; each factor matters. Rock hardness and bit design impact it. Conditions change as you drill deeper or hit different materials, requiring constant adjustments.

Practical Example: Split Skirt Condition

Let's discuss the "split skirt condition." During a project, my DTH button bit cracked like an eggshell due to misalignment and wrong feed pressure. Uneven stress created fatigue cracks.

| Cause | Effect on Bit |

|---|---|

| Misalignment | Uneven forces, increasing crack risk |

| Insufficient Pressure | Inadequate contact, leading to wear |

| Excessive Pressure | Undue stress, resulting in structural damage |

Optimizing Drilling Operations

Real-time feedback is very helpful to me. Advanced sensors and analytics help me monitor pressure levels5, keeping operations running smoothly and avoiding unexpected downtimes and extra costs.

Conclusion

There is no one-size-fits-all solution, but understanding feed pressure helps operators make informed adjustments during drilling operations. Knowing how it affects bit integrity allows quick adjustments. Focusing on proper setup and constant monitoring helps bits last longer, avoiding costly drilling interruptions.

Correct feed pressure extends drill bit lifespan.True

Proper pressure ensures optimal contact, reducing wear and cracking.

Excessive feed pressure prevents bit cracking.False

Too much pressure can lead to structural damage and cracking.

Are worn-out retaining rings a common issue?

I remember the first time a small retaining ring gave me a big problem. It's surprising how these little things decide if machines work or not. Are worn-out retaining rings really a usual problem? Let's explore this.

Old retaining rings are a frequent problem in mechanical systems. These systems face constant use and stress. Regular checks really help identify worn-out rings. Timely replacements are crucial to prevent possible misalignments. Fixing them early prevents component failures.

Understanding the Role of Retaining Rings

Retaining rings, often small and unnoticed, play a huge role in machines. People also call them snap rings. They keep parts securely in place on shafts or inside holes, preventing parts from moving during operation. Think of them as the team behind the scenes that keeps everything going smoothly. However, like all mechanical parts, they wear out over time due to repeated stress cycles6.

Causes of Wear and Tear

I have discovered through tough experiences that several factors ruin these small but crucial rings:

- Material Fatigue: Imagine bending a paperclip until it breaks. That's similar to metal fatigue. Stress gathers and cracks or breaks eventually show.

- Improper Installation: I once assembled a swing set without reading instructions - it didn't end well. If these rings aren't installed correctly, they experience unnecessary stress.

- Environmental Conditions: Harsh environments are like bad wedding weather. Extreme temperatures or corrosive substances speed up their wear and tear.

Signs of Worn-Out Retaining Rings

Noticing when a ring needs help can save you from expensive problems later:

- Visible Damage: If you see bends or breaks, action is necessary.

- Loose Fit: A ring that doesn't fit tightly is a warning sign.

- Frequent Adjustments Needed: Constantly reaching for tools might mean a ring is failing.

Preventative Measures

Being proactive is key. Here is what I find useful:

- Scheduled Inspections: Regularly check all mechanical parts, including retaining rings.

- Use Quality Materials: Choose high-quality materials that resist fatigue and damage.

- Proper Installation Techniques: Always follow the manufacturer's instructions.

Exploring Solutions and Alternatives

Depending on your system's needs, consider different strategies:

| Solution | Description |

|---|---|

| Regular Replacement | Replace rings at set intervals to prevent unexpected failures. |

| Material Upgrade | Use materials with higher fatigue resistance. |

| Design Alterations | Consider design changes that distribute stress more evenly. |

For more detailed advice on solving these issues, visit expert talks on specialized mechanical forums7. Understanding the problems and applying strong solutions can help systems run smoothly and reliably.

Retaining rings can crack due to material fatigue.True

Continuous stress cycles cause metal fatigue, leading to cracks.

Improperly installed retaining rings last longer.False

Incorrect installation increases stress, shortening the ring's lifespan.

Can Excessive Torque Lead to Structural Failures?

Ever felt confused by a strange machine breaking down? I have. Often, the cause is something simple like torque.

Too much torque very often leads to structural breakdowns. It overstrains materials. This stress causes fractures, deformations or problems in functioning. Proper torque specifications help avoid these issues. Regular maintenance also really helps.

Understanding Torque and Its Application

Imagine tightening a bolt. You wonder if it's too tight or too loose. That idea is torque - finding the right balance. Torque is the force that twists an object. In machines, torque is very important. I learned that using the right torque helps things work well and last longer. It's like tuning a guitar string; too tight and it might break.

Torque is a measure of rotational force applied to an object. In mechanical systems, it is crucial to apply the right amount of torque to ensure the proper functioning and longevity of components. Torque specifications are designed based on material strength and operational demands.

How Excessive Torque Causes Failures

-

Material Overstress: I have seen it. Too much torque can break materials that can't stretch much, causing permanent deformations or fractures. This happens often to brittle materials that break easily when stretched.

-

Joint Failures: Think about a door hinge that loosens because of over-tightening. In machines, too much torque stretches bolts beyond their yield strength, leading to joint failures. This weakens joints and could cause a big breakdown.

-

Equipment Damage: Picture driving with misaligned wheels. Too much torque can also misalign bearings and shafts in machines, leading to premature wear and damage, resulting in unexpected downtimes8 which are really expensive and annoying.

Preventing Structural Failures

Over time, I learned that stopping problems before they start really helps. Following the manufacturer's torque guidelines, checking regularly, and using the right tools is necessary.

Here's a simple table illustrating preventive measures:

| Measure | Description |

|---|---|

| Torque Wrench Usage | Use calibrated torque wrenches for precise application |

| Regular Inspections | Conduct routine inspections to identify overstressed components |

| Training and Guidelines | Provide training on proper torque application techniques |

Smart monitoring systems are great too; they watch torque levels in real-time and catch problems early, preventing failures effectively.

Real-World Examples and Insights

Consider bridge construction9. I know of cases where wrong torque on fasteners caused structural problems. Precision with torque in such projects is very important.

In cars, I have heard stories of wheels falling off due to incorrect lug nut torque at high speeds—a terrifying thought for drivers.

These examples remind me of how critical precise torque application is. Precision keeps people safe and maintains integrity in many industries.

Excessive torque can lead to bolt joint failures.True

Over-torquing stretches bolts beyond yield strength, causing failures.

Using any wrench ensures proper torque application.False

Only calibrated torque wrenches ensure accurate torque application.

How Does Material Fatigue Impact DTH Bit Longevity?

Picture yourself deep in a drilling project. Everything progresses smoothly. Suddenly, boom! A bit fails without warning. Knowing about material fatigue really saves the day.

Material fatigue in DTH bits results in micro-cracks. These cracks slowly weaken the bit. This process shortens its lifespan. Selecting the right materials helps solve this problem. Adjusting operational settings also helps. These steps extend the life of your drilling tools. Your tools really last longer.

Understanding Material Fatigue in DTH Bits

I recall my first experience with material fatigue. It was eye-opening, indeed. I was at a lively construction site where I observed how repeated stress from the constant hammering of DTH bits caused tiny cracks. Initially, these seemed insignificant, like small cracks you might ignore on an old coffee mug. Over time, however, these cracks expanded. They weakened the bit and led to sudden failures.

Material fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. In DTH bits, the constant hammering motion during drilling causes repeated stress cycles. Over time, this can lead to the formation of micro-cracks, which propagate and eventually cause failure.

Factors Contributing to Material Fatigue

- Material Composition: Imagine using high-quality steel and tungsten carbide10 in bits. It’s like picking a strong SUV for a long road trip. Good materials mean better resistance to fatigue.

- The type of steel and tungsten carbide used in the bit influences its resistance to fatigue. High-quality materials with uniform microstructures typically offer better fatigue resistance.

- Operational Conditions: Picture driving with incorrect tire pressure; similar mistakes in drilling speed and pressure increase stress on the bit.

- Factors like drilling speed, feed pressure, and rotational speed impact the level of stress experienced by the bit. Optimizing these parameters can reduce the stress cycles.

- Environmental Conditions: Picture drilling in corrosive surroundings without protection.

- Exposure to abrasive or corrosive environments accelerates fatigue. Using protective coatings or selecting materials with inherent resistance can be beneficial.

| Factors | Impact on Fatigue |

|---|---|

| Material Composition | High-quality materials improve fatigue resistance. |

| Operational Conditions | Proper parameters reduce stress cycles. |

| Environmental Conditions | Protective measures can mitigate damage. |

Reducing Material Fatigue

- Material Choice: Think of picking a reliable pair of boots for hiking; choosing materials with high strength is crucial for prolonging bit life11.

- Choosing materials with high tensile strength and toughness is crucial for enhancing bit longevity.

- Design Improvements: Adding features such as stress relief grooves is similar to ergonomic design in furniture.

- Incorporating features like stress relief grooves can help distribute loads more evenly, reducing localized stress concentrations.

- Regular Maintenance: Conducting regular checks and replacing components in time is like keeping your car’s oil fresh.

- Routine inspections and timely replacement of worn components prevent excessive stress buildup.

Real-world Uses

In industries, we often use advanced monitoring systems like health trackers for equipment. Smart drilling technologies12 with sensors collect real-time data allowing quick adjustments to reduce fatigue impact.

Industries often employ advanced monitoring systems to track bit wear and predict failure by utilizing sensors that gather data on operational conditions, allowing for real-time adjustments to minimize fatigue impact.

Understanding how material fatigue influences DTH bits lets companies extend their equipment's lifespan—just like good personal habits extend life—leading to significant cost savings and improved operational efficiency.

High-quality materials reduce DTH bit fatigue.True

High-quality materials with uniform microstructures enhance fatigue resistance.

Drilling speed doesn't affect DTH bit stress.False

Drilling speed impacts stress cycles experienced by the bit.

How Can I Prevent Split Skirts in DTH Button Bits?

I remember my first drilling project. Everything that possibly went wrong happened. I learned how to stop split skirts in DTH button bits. This knowledge changed the situation.

Reduce the chance of split skirts in DTH button bits by aligning them correctly. Very important. Keep the feed pressure at the best level. Use really high-quality materials. Inspect equipment often and regularly.

Proper Alignment

Have you ever been on a drilling site where everything goes wrong? I remember a time when bits kept breaking and causing long delays. That taught me the need for correct alignment. Setting up the drilling rig correctly is important to stop uneven force from causing split skirts13. Regular rig checks and adjustments really help avoid many problems.

Ensuring the drilling rig is correctly aligned is crucial to avoiding uneven force distribution, which often leads to the split skirt condition. Misalignment can cause severe stress concentrations, making it essential to regularly check and adjust the rig setup.

Optimal Feed Pressure

Finding the right feed pressure also prevents splits. Low pressure increases wear and cracking risk. High pressure causes too much stress. I realized this when my team drilled tough rock. We spent an afternoon modifying the pressure until it suited the conditions.

Maintaining appropriate feed pressure is vital:

| Feed Pressure | Impact on Bit |

|---|---|

| Too Low | Increased wear, potential cracking |

| Optimal | Efficient contact, reduced stress |

| Too High | Excessive stress, risk of splitting |

Monitoring and adjusting the feed pressure based on rock hardness and drilling conditions will help in preventing stress on the bit.

Use of Quality Materials

Selecting high-quality materials for bits matters a lot. Good materials resist wear and fatigue. I've observed bits made from poor materials fail fast, causing costly downtime and replacements.

Opt for bits made from high-quality materials that offer better resistance to wear and fatigue. Material fatigue over time can lead to splits, so choosing durable materials and conducting regular inspections can extend the life of the bits.

Regular Equipment Inspection

Never ignore routine checks of retaining rings and other parts. Worn parts lead to misalignment and higher split risk. Regular inspections catch such issues early. Preventive maintenance saves much time and money.

Routine checks of retaining rings and other supportive equipment components are necessary. Worn-out retaining rings can fail to provide adequate support, leading to misalignment and increasing the risk of a split skirt.

Training and Awareness

Training operators to notice too much torque and bad drilling conditions avoids extra equipment stress. Offering full training materials improves work habits. It also gives the team power to handle situations well.

- Training guides14 for drill operators really help in managing equipment better.

- Awareness sessions about noticing stress signs in equipment should be a part of regular safety checks.

Proper alignment prevents uneven force distribution.True

Correct alignment avoids stress concentrations, reducing split risk.

High feed pressure reduces wear on drilling bits.False

Excessive pressure increases stress, risking bit splitting.

Conclusion

The split skirt condition in DTH button bits arises from misalignment, improper feed pressure, excessive torque, and material fatigue, leading to performance issues and costly downtime.

-

Learn more about DTH button bits and their applications in various drilling operations. ↩

-

Discover how split skirt conditions impact the performance and safety of drilling bits. ↩

-

Explore methods to enhance drilling efficiency by ensuring proper alignment. ↩

-

Discover why insufficient feed pressure can lead to premature equipment failure. ↩

-

Explore how sensors help maintain optimal drilling conditions, reducing costs. ↩

-

Clicking this link will provide detailed insights into why retaining rings experience material fatigue. ↩

-

Explore discussions and solutions shared by experts in mechanical forums regarding retaining ring problems. ↩

-

Learn about the effects of excessive torque on rotating machinery and how it leads to misalignments and premature wear. ↩

-

Explore real-world examples where improper torque application led to structural failures, providing insights into preventive measures. ↩

-

Explore tungsten carbide's role in enhancing drill bit toughness and resistance to fatigue. ↩

-

Discover strategies for increasing the lifespan of drill bits through material and design choices. ↩

-

Learn about innovative technologies that improve drilling efficiency and reduce equipment wear. ↩

-

Proper alignment ensures even force distribution, reducing stress points and preventing skirt splits. ↩

-

Training guides offer essential tips on managing drilling equipment efficiently, enhancing operator skills. ↩