Have you ever thought about whether your button bits work at their best? Good care could be the key.

To care for button bits, people need to inspect them regularly. They should look for wear and damage. People should clean them after each use. Grinding the buttons helps keep their shape. Folks must handle them gently. Correct storage is important. People should operate within recommended limits. These steps extend the life of the bits. This really improves drilling efficiency.

Every time I receive new button bits, I remember my first drilling job. Ignoring a small crack wasted hours. This is a simple lesson. Checking for wear or damage saves a lot of trouble later. I found out that proper care is very important. Every step, from cleaning to grinding, keeps the bits sharp and effective.

Knowing these maintenance techniques goes beyond a checklist. It involves understanding the tools as work partners. Proper care results in fewer replacements. Workflows become smoother. This leads to less stress when performance truly matters.

Regular inspections extend button bit lifespan.True

Regular inspections help identify wear and damage early, prolonging use.

Cleaning button bits after use is unnecessary.False

Cleaning prevents residue buildup, ensuring efficiency and longevity.

How Do I Inspect Button Bits Properly?

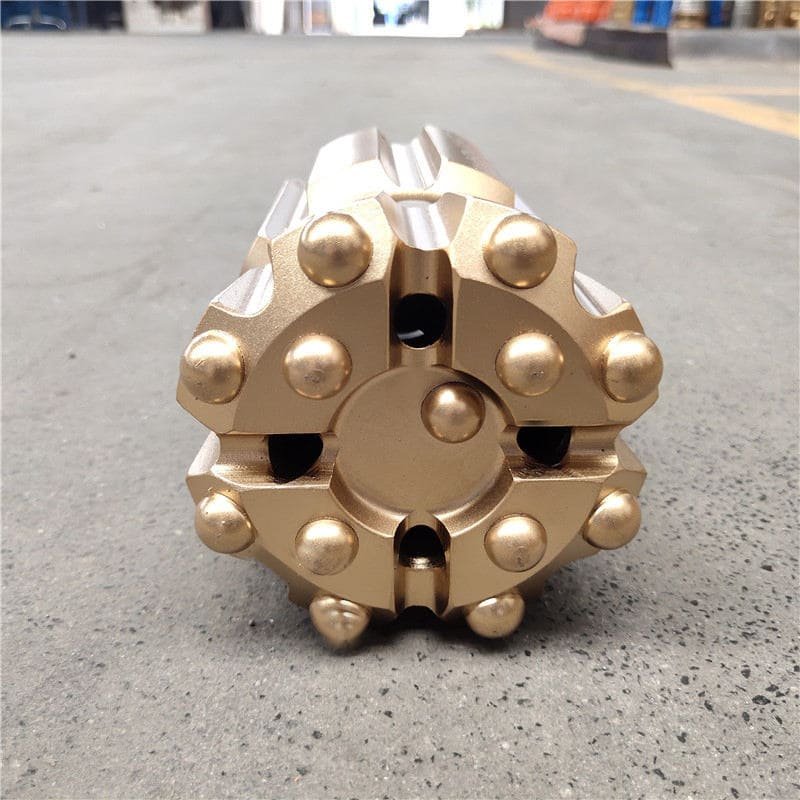

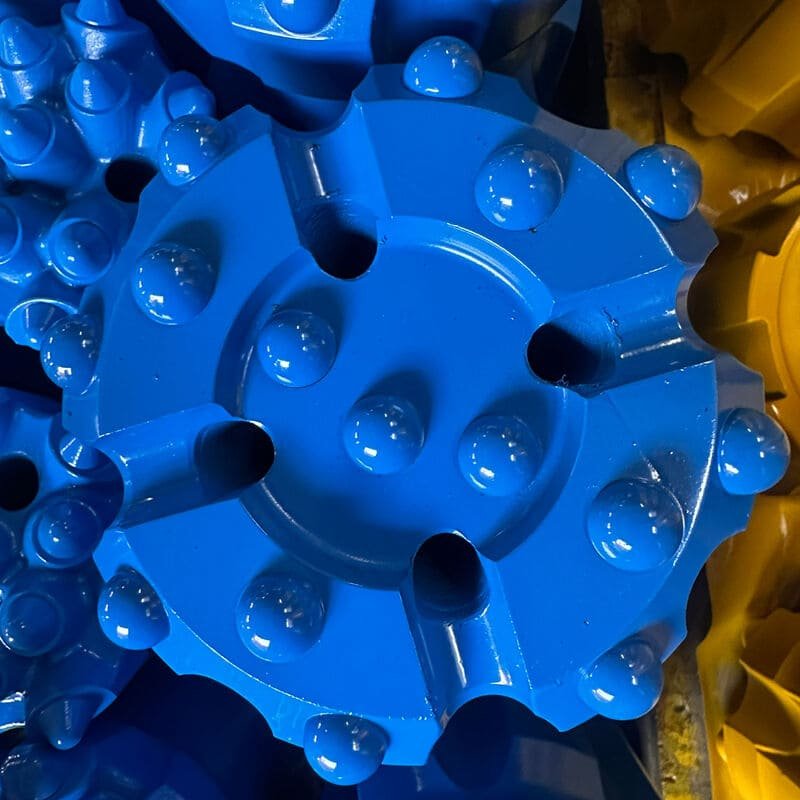

Checking button bits might seem ordinary. However, it plays a crucial role in successful drilling work. Button bits are like hidden champions. These small but powerful tools are vital for efficient and durable performance. Keeping them in excellent condition is very important.

Inspecting button bits includes checking wear and cleaning debris. Workers grind buttons and handle them carefully. Keeping usage records is also important. These steps are very important for the best performance. They help ensure long life in drilling applications.

Routine Checks

Imagine you're about to start an exciting road trip. You would check your car for problems, right? Inspecting button bits is similar. I first look for signs of damage or wear. Missing buttons? That's like missing a wheel! Finding issues early, such as misaligned or worn buttons, saves bigger problems later. Sometimes, a simple regrinding or replacement1 is all it needs.

| Inspection Area | Key Signs to Watch |

|---|---|

| Wear Patterns | Uneven surfaces |

| Cracks | Visible fractures |

| Button Protrusion | Misalignment |

Cleaning Procedures

Neglecting to clean button bits leads to trouble. After drilling, rock cuttings and debris are removed with brushes and air jets. I learned to avoid harsh chemicals; they really do more harm than good. It’s like brushing your teeth to keep them healthy.

Grinding and Sharpening

Sharp, well-shaped buttons are absolutely necessary. Proper equipment is used to keep buttons at their original shape without overheating. Poor grinding reduces efficiency and increases wear, much like a dull knife that just doesn't work properly. Ensure grinding restores the buttons to their original profile as incorrect grinding can increase wear and tear2.

Handling and Storage

Handling bits carefully is like handling delicate glassware. Dropping them causes cracks. They’re stored in a clean, dry area organized to stop them from hitting each other.

Usage Recording

Detailed records of bit usage are my secret tool for efficiency. They help predict maintenance and plan replacements before they are urgent. This proactive method is essential for smooth operations as it supports timely maintenance by anticipating maintenance needs3.

Routine checks prevent button bit damage.True

Regular inspections help detect issues early, preventing damage.

Harsh chemicals are recommended for cleaning bits.False

Harsh chemicals can damage materials; use brushes and air jets.

How Does Cleaning Affect the Performance of Button Bits?

You won't believe how a simple cleaning habit changes button bit performance. Truly, it's like night and day!

Regular cleaning of button bits eliminates debris. Bits avoid wear this way. Clean bits perform better. Proper function happens with regular cleaning. Downtime reduces with maintenance. It keeps sharpness intact. Bit life extends. Efficiency stays high.

Importance of Regular Cleaning

I remember the first time I saw how important regular cleaning was for button bits. Imagine this: after a day of drilling, I did not clean the bits well. The next day, drilling was slow. I had to stop to clean the debris. Since then, I clean them all the time. Clean button bits stop rock pieces and mud from sticking. This problem can really mess with their efficiency.

By maintaining cleanliness, operators can ensure that the drilling equipment4 functions optimally, reducing operational downtime.

Cleaning Techniques and Tools

Finding the right tools is very important. I tried different cleaning methods. Trust me, brushes and air jets work best. They remove debris without harming the bit's surface. Stay away from harsh chemicals; they really strip away protective coatings.

A simple table below illustrates suitable cleaning tools:

| Tool | Function |

|---|---|

| Brushes | Remove loose debris |

| Air Jets | Blow out fine particles and dust |

| Soft Cloths | Wipe away residues |

Effects of Cleaning on Button Life

Consistent cleaning gives better performance and longer life for button bits. It's amazing how stopping debris build-up reduces overheating and damage risks.

Regular maintenance keeps the carbide buttons sharp, which is crucial for drilling through hard rock.

Cleaning saves me a lot of money and headaches.

Understanding how cleaning impacts5 bit longevity can lead to cost savings and improved operational efficiency.

Case Studies and Practical Insights

I read about a mining company that started strict cleaning routines. It saw a 20% cut in bit replacement costs. This inspired me; I used similar routines and noticed big performance improvements.

These practices really help in demanding environments; they offer big strategic benefits.

Integrating these insights into everyday maintenance routines can help operators achieve consistent results, offering further strategic advantages6 in demanding drilling environments.

Regular cleaning prevents button bit wear.True

Cleaning removes debris, reducing friction and premature wear.

Harsh chemicals are ideal for cleaning button bits.False

Harsh chemicals can damage protective coatings on bits.

Why Is Correct Grinding Crucial for Button Bit Maintenance?

Ever asked yourself why your drilling activities suddenly face problems at very bad times?

Proper grinding of button bits keeps their sharpness and shape. This really improves penetration rates and operational efficiency. It also reduces wear. This probably lowers downtime. It also extends the life of your drilling tools.

The Role of Grinding in Keeping Bits Sharp

Grinding helps maintain the shape and sharpness of button bits, crucial for efficient penetration in drilling operations. I recall when a veteran driller was grinding button bits with great care. It seemed really boring then, but once I started drilling, I saw why it was so important. Grinding makes bits sharp, which is essential for cutting through materials easily. Frequent grinding sessions keep them biting into the earth smoothly. This saves us from bad downtime7.

| Aspect | Impact of Proper Grinding |

|---|---|

| Penetration Rate | Maintains high penetration speeds |

| Wear and Tear | Reduces unnecessary wear and prolongs tool life |

| Operational Costs | Lowers costs by extending the time between bit changes |

Effects of Poor Grinding

Incorrect grinding can lead to uneven wear on button bits. I thought I could skip some grinding to save time once. Big mistake! Uneven wear happened, lowering performance and raising costs. Bits got too hot and damaged my tools. Misaligned buttons slowed drilling and wasted more bits.

- Reduced Speed: Bits with misaligned buttons speed drills slower due to uneven pressure.

- More Wear: Bits with poor grinding wear out quickly, needing more replacements.

- Reduced Efficiency: Misaligned buttons can cause uneven force distribution, reducing drilling speed.

- Increased Wear: Incorrectly ground bits wear out faster, necessitating more frequent replacements.

Best Practices for Grinding Button Bits

To avoid these problems, use appropriate grinding tools that prevent overheating and ensure precise shaping. Employing high-quality equipment tailored to the specific material of the button bits is critical. Regular inspections can help determine when regrinding8 is necessary.

Suggested Tools and Methods:

- Coolant Use: Stops overheating during grinding.

- Exact Tools: Restore button shapes accurately.

- Regular Checks: Spot wear early and fix it in time.

Grinding maintains button bit penetration rates.True

Proper grinding keeps bits sharp, ensuring high penetration speeds.

Overheating during grinding improves carbide properties.False

Overheating alters carbide negatively, reducing bit performance.

How Can You Safeguard Your Button Bits?

Have you ever thought about keeping button bits in great condition? Maintaining these tools properly is very important. Regularly check them for any signs of damage or wear. This step really helps to extend their lifespan. Clean button bits after each use to prevent dirt buildup. Proper storage is also key. Keep them in a dry and safe place to avoid rust. Regular maintenance probably helps them perform better too.

Check button bits carefully for wear and tear. Clean them after using. Store them in a dry location. Use racks or containers. This prevents damage from drops or from touching other tools.

Regular Inspection

Routine checks have significant power. Before putting my button bits away, inspect them thoroughly9 for any signs of wear or damage. Tiny cracks or signs of wear can cause issues later, so spotting them early matters a lot. Maintaining a log helps to know when each bit might need care.

| Inspection Checklist | Frequency |

|---|---|

| Visual inspection | After each use |

| Performance logging | Weekly |

| Wear assessment | Monthly |

Proper Cleaning

After a long drilling day, cleaning my button bits feels calming. It washes away stress and prevents debris from impacting their work. Use soft brushes and air jets instead of harsh chemicals to preserve material integrity.

- Tools Needed: Soft brushes, air compressors

- Avoid: Chemicals that harm coatings

Correct Handling Practices

Tossing my bits into any old toolbox was a mistake I learned the hard way. Now I use cushioned containers to transport them. Avoiding bumps and drops is valuable.

- Tip: Use containers that absorb impacts

- Caution: Wear gloves to avoid grease transfer

Optimal Storage Solutions

Storing button bits in a dry organized place is not just neat; it is essential. I once found rusted bits because they were in a damp garage corner. Now I use individual racks to keep them from hitting each other.

| Storage Condition | Ideal Setup |

|---|---|

| Temperature | Room temperature |

| Humidity | Low, controlled |

| Arrangement | Individual holders |

Use of Lubricants and Cooling

Proper lubricants during operations really change things for me by reducing friction and stopping overheating, which extends the life of the bits.

- Lubrication: Check compatibility with bit material

- Cooling: Keep adequate cooling systems during use

Adjusting Operational Parameters

Following recommended operational settings like speed and pressure really benefits me. It's tempting to push harder in tough conditions, but adjusting these based on what I drill into makes a huge difference in saving my tools.

By following these steps, I have extended the life of my button bits. My drilling projects became safer and more cost-effective with minimal upfront effort for peace of mind later.

Button bits should be visually inspected after each use.True

Regular visual inspections help identify damage early, ensuring safety.

Use harsh chemicals to clean button bits thoroughly.False

Harsh chemicals can corrode the material; use brushes or air jets.

How Do Lubrication and Cooling Affect Button Bit Longevity?

Picture drilling through tough rock. Feel the strength of your tools due to proper lubrication and cooling.

Lubrication and cooling really help button bits last longer. They cut down friction and get rid of heat. This prevents wear and stops thermal damage to the carbide buttons. Less wear means the bits perform better and save money. Drilling operations become more efficient this way. Efficiency really improves.

Understanding Lubrication in Button Bits

I discovered the value of lubrication during a difficult drilling task. My equipment felt like it might fail, so I wanted to understand how it worked. Lubrication acts like a calming balm, reducing friction between the button bit and the drilled area. It's amazing how reducing friction makes the bit last longer. A sharp and effective bit really improves performance.

Various lubricants are used depending on the drilling environment, such as oil-based lubricants in wet conditions or dry lubricants for dusty environments.

Benefits of Proper Lubrication

| Benefit | Description |

|---|---|

| Reduced Wear | Minimizes abrasive contact, prolonging bit life. |

| Heat Reduction | Decreases heat from friction, preventing structural damage. |

| Improved Efficiency | Ensures smoother operation, increasing penetration rates. |

Once I focused on proper lubrication, I saw less material clogging on the bits. This was a real game-changer for keeping them effective during long sessions.

The Importance of Cooling

Cooling caught my attention during a tough job with overheating problems. Cooling stops overheating, which leads to early bit failure. Trust me, that's not something you want in the middle of work.

Cooling Methods

- Fluid Circulation: This method refreshes the drill using water or oil-based fluids to remove heat and debris.

- Air Flushing: Where liquids aren't an option, air flushing helps cool the bit efficiently.

| Cooling Method | Application | Advantages |

|---|---|---|

| Fluid Circulation | Wet environments | Effective heat removal and debris clearance. |

| Air Flushing | Dry or sensitive environments | Provides cooling without introducing moisture. |

Impact on Bit Longevity

Keeping bits cool prevents thermal expansion that cracks carbide buttons. Effective cooling10 acts like insurance for the structural integrity of bits; they probably stay useful for a much longer time.

Combining Lubrication and Cooling for Maximum Effectiveness

Combining these strategies felt like finding a sweet spot in drilling. It cut down maintenance needs very effectively, making operations more cost-efficient.

- Operational Efficiency: A well-lubricated and cooled bit works at its best with minimal breaks.

- Cost Savings: Less wear and tear lead to fewer replacements and repairs.

- Enhanced Safety: Lower equipment failure risk reduces site dangers.

Understanding lubrication and cooling helps optimize drilling operations by ensuring your button bits perform reliably across various conditions. For more insights on optimizing drilling parameters, explore our detailed guide11.

Lubrication reduces button bit wear rate.True

Lubrication minimizes friction, decreasing abrasive contact and wear.

Cooling prevents button bit thermal expansion.True

Cooling keeps temperatures low, avoiding thermal expansion and cracking.

How Do Operating Parameters Influence Button Bit Wear?

Do you ever think about why some button bits last a really long time?

Operating parameters such as rotational speed, weight on bit and flushing rates are crucial for managing button bit wear. Adjust these settings according to the rock type and drilling conditions. This approach helps extend the lifespan of the bits. The efficiency of drilling probably improves too.

Impact of Rotational Speed

I remember my first deep drilling project very clearly. There was intense focus on setting the correct rotational speed. Speeding up too much could lead to bits overheating quickly and wearing down faster than melting ice cream. But if the speed was too low, it felt like drilling through thick syrup. Hitting the perfect RPM was crucial; it matched the rock properties12 perfectly. It really made all the difference.

| Rock Type | Recommended RPM | Impact on Wear |

|---|---|---|

| Soft | Lower RPM | Reduced Wear |

| Hard | Higher RPM | Increased Wear |

Importance of Weight on Bit (WOB)

I once worked with a team who constantly adjusted the Weight on Bit (WOB). It was like adding the right amount of seasoning to food. We learned that too much WOB is like pressing down too hard on a pencil—you get more lead but might break it. On the other hand, too little WOB is like trying to write without touching the paper. The challenge was keeping a balance:

- High WOB: Increases penetration but could wear out the bit rapidly.

- Low WOB: Slows wear but might slow down drilling.

The balance between sufficient force and optimal performance should be maintained by monitoring WOB adjustments.

Flushing Rates and Their Effects

Flushing rates are another key factor. It's like keeping a car engine cool on a long drive. Proper flushing removes debris and keeps the bit cool, similar to cooling fans in electronics. I recall one time when poor flushing led to debris build-up, causing unnecessary friction and wear—a costly mistake.

- High Flushing Rate: Keeps cool but maybe increases costs.

- Low Flushing Rate: Saves money but risks overheating.

Finding the right balance requires assessing the drilling environment13.

Adjustments Based on Drilling Conditions

In my experience, no two drilling sites are alike. Each site has its own challenges. Adjusting operating settings to these conditions is like tuning an instrument—it needs precision and attentiveness. In abrasive conditions, operators should lower RPM and increase flushing rates; this probably prolongs the bit's life.

Operators should continuously assess conditions and adjust accordingly to maintain efficiency. I've seen real-time monitoring systems help operators a lot; these systems allow dynamic adjustments, improving both performance and cost-efficiency.

Exploring case studies where such adjustments have led to improved outcomes can provide valuable insights into effective parameter management strategies.

By considering these elements, drilling operations can really improve—they save time and reduce costs, ensuring equipment lasts longer.

High RPM increases button bit wear due to friction.True

High rotational speeds generate more friction and heat, accelerating wear.

Low flushing rates reduce button bit operational costs.True

Lower flushing rates are cost-effective but risk overheating and clogging.

Conclusion

Proper care for button bits includes regular inspections, cleaning, grinding, careful handling, and optimal storage to extend their lifespan and improve drilling efficiency.

-

Explore methods for regrinding or replacing drill bits to maintain their functionality and efficiency. ↩

-

Discover best practices for grinding drill bits to ensure their longevity and optimal performance. ↩

-

Learn about the significance of record-keeping for predicting maintenance schedules and improving efficiency. ↩

-

Understand the broader importance of maintaining drilling equipment to ensure long-term operational efficiency. ↩

-

Discover how proper cleaning extends the lifespan of drilling tools, leading to cost savings and efficiency. ↩

-

Explore real-world examples of how systematic cleaning enhances equipment performance and reliability. ↩

-

Understanding how to minimize downtime can significantly improve operational efficiency and reduce costs. ↩

-

Discover the signs indicating it's time to regrind your button bits for maintaining peak performance. ↩

-

Gain insights into effective inspection methods for early detection of wear and damage. ↩

-

Explore how effective cooling preserves carbide button integrity and extends their life. ↩

-

Discover comprehensive strategies for maintaining button bits and ensuring optimal performance. ↩

-

Discovering optimal RPM for different rock types helps in minimizing wear while maintaining efficiency. ↩

-

Identifying ideal flushing rates ensures effective cooling and debris removal, reducing wear. ↩