In the dynamic field of drilling, choosing the right bit can make or break a project.

PDC bits outperform tricone bits mainly due to their superior speed, efficiency, and longevity, especially in non-abrasive rock formations. They offer higher rates of penetration and lower operational costs, making them a preferred choice in suitable conditions.

While PDC bits shine in many scenarios, understanding when and why they excel over tricone bits is crucial for optimizing drilling operations. Let's delve deeper into the factors that make PDC bits stand out, ensuring you make the best choice for your next project.

PDC bits offer faster drilling speeds than tricone bits.True

PDC bits are designed for high penetration rates, especially in soft to medium formations.

What Are the Key Advantages of PDC Bits Over Tricone Bits?

Drilling success hinges on choosing the right bit for specific geological challenges.

PDC bits offer unmatched speed, efficiency, and durability compared to tricone bits, particularly in less abrasive formations. They ensure faster penetration rates and reduced operational costs, making them ideal for many drilling scenarios.

Understanding the Efficiency of PDC Bits

PDC (Polycrystalline Diamond Compact) bits are revered for their ability to maintain high penetration rates due to the unique material properties1 of synthetic diamonds. This allows for minimal downtime during drilling operations as PDC bits require fewer trips for bit changes compared to tricone bits.

Moreover, the solid design of PDC bits facilitates smoother drilling and better stability, which translates to less vibration and wear. This efficiency is further amplified in softer rock formations where PDC bits can deliver exceptional performance.

Speed and Penetration: A Comparative Analysis

The design of PDC bits lends itself to higher rotational speeds compared to tricone bits. The lack of moving parts in a PDC bit reduces friction and energy loss, allowing for rapid progress through formations. This can be particularly beneficial in time-sensitive projects where every minute saved counts.

In contrast, tricone bits often experience slower penetration rates due to the complex interaction of their rotating cones and cutting elements, which are better suited for dealing with harder and more variable geological conditions.

Longevity and Cost-Effectiveness

Another significant advantage of PDC bits is their longevity. The diamond cutters on these bits are incredibly durable, meaning they last longer than the rolling elements of a tricone bit. This durability translates into reduced overall costs as fewer bits are needed over the lifespan of a project. Understanding the cost dynamics2 can help in budgeting effectively for drilling operations.

However, it is important to note that the initial cost of PDC bits can be higher than tricone bits. Yet, when accounting for their lifespan and reduced need for replacements, the long-term cost benefits often outweigh the upfront expense.

PDC bits last longer than tricone bits.True

PDC bits' diamond cutters are more durable, reducing replacements.

Tricone bits are faster in soft formations than PDC bits.False

PDC bits excel in soft formations due to higher speeds and efficiency.

How Do Geological Conditions Affect the Performance of PDC and Tricone Bits?

The choice between PDC and tricone bits isn't just about preference—geology plays a key role.

Geological conditions significantly impact the performance of PDC and tricone bits. PDC bits excel in stable, non-abrasive formations due to their speed and efficiency, whereas tricone bits are better suited for varied, hard rock environments thanks to their ruggedness and adaptability.

Understanding Geological Influences

The performance of PDC bits3 and tricone bits is profoundly influenced by geological conditions. In stable and predictable formations, PDC bits shine because they can penetrate quickly and sustain less wear. Their design allows for continuous shearing action, making them ideal for softer sedimentary rocks.

However, in abrasive or hard rock environments, tricone bits take the lead. Their rolling cone design with multiple cutting edges provides versatility and robustness, allowing them to handle variable conditions with ease. This makes them indispensable in drilling operations that encounter mixed lithologies or require adaptability.

Comparison of Bit Performance in Different Formations

| Geological Condition | Preferred Bit Type | Performance Attributes |

|---|---|---|

| Non-abrasive Sedimentary | PDC | Fast penetration, lower wear |

| Hard, Abrasive Rock | Tricone | Durability, adaptability, handling variations |

| Unpredictable Formations | Tricone | Versatility, ability to manage heterogeneity |

The Role of Rock Hardness and Abrasiveness

Rock hardness and abrasiveness are critical factors that determine bit selection. PDC bits perform optimally in formations where the abrasiveness is low, minimizing wear on the cutters. Conversely, tricone bits are designed to withstand high wear and tear due to their robust structure, making them suitable for hard, abrasive conditions.

Understanding these geological nuances helps in making informed decisions about bit selection, ensuring efficient drilling operations while minimizing costs and maximizing productivity. For more insights into how these factors come into play, you might explore detailed comparisons of drilling bits4.

PDC bits excel in non-abrasive formations.True

PDC bits perform best in stable, non-abrasive environments due to speed.

Tricone bits are unsuitable for hard rock environments.False

Tricone bits are ideal for hard rock due to their durability and adaptability.

What Are the Cost Implications of Using PDC Versus Tricone Bits?

Choosing between PDC and tricone bits involves weighing various cost factors.

PDC bits typically have a higher initial cost but lower long-term operational expenses, while tricone bits may incur more frequent replacements and maintenance costs.

Initial Purchase Cost

When considering initial investment5, PDC (Polycrystalline Diamond Compact) bits are generally more expensive than tricone bits. This higher cost stems from their advanced manufacturing process and the use of synthetic diamonds. However, this upfront cost can be offset by their performance and longevity in suitable drilling environments.

Operational Costs

PDC bits often provide lower operational costs due to their ability to maintain high rates of penetration and reduced need for bit changes. In consistent, softer formations, they can drill faster and last longer, which minimizes downtime and labor costs. On the other hand, tricone bits may require more frequent replacements, especially in abrasive or hard rock formations, leading to increased operational expenditures.

| Cost Component | PDC Bits | Tricone Bits |

|---|---|---|

| Initial Cost | High | Moderate |

| Replacement | Less Frequent | More Frequent |

| Efficiency | High | Variable |

Maintenance and Durability

PDC bits require less maintenance due to their durability in non-abrasive conditions. Their design allows for fewer moving parts compared to tricone bits, reducing wear and tear. In contrast, tricone bits, with their rotating cones and multiple bearings, can suffer from mechanical failures more often, increasing maintenance costs.

Suitability for Geological Conditions

The choice between PDC and tricone bits should also consider the geological conditions of the drilling site. PDC bits excel in uniform formations, offering a cost-effective solution over time despite their initial higher price. Conversely, tricone bits are better suited for challenging terrains where their ruggedness can be justified despite potential higher cumulative costs due to maintenance and replacement needs.

Economic Analysis

For decision-makers, conducting a cost-benefit analysis6 is essential. This includes evaluating the total lifecycle costs of the bits in relation to the specific drilling conditions. Factors such as expected bit life, rate of penetration, and potential downtime should be calculated to determine the most economically viable option.

PDC bits have lower long-term operational costs.True

PDC bits last longer and need fewer replacements, reducing costs.

Tricone bits are cheaper in initial investment.True

Tricone bits cost less upfront due to simpler manufacturing.

When Should Tricone Bits Be Preferred Over PDC Bits?

Understanding when to choose tricone bits over PDC bits is crucial for efficient drilling operations.

Tricone bits are preferred in abrasive, hard, and varied rock formations where PDC bits might falter. Their durability and adaptability make them ideal for complex drilling environments, ensuring operational success in challenging terrains.

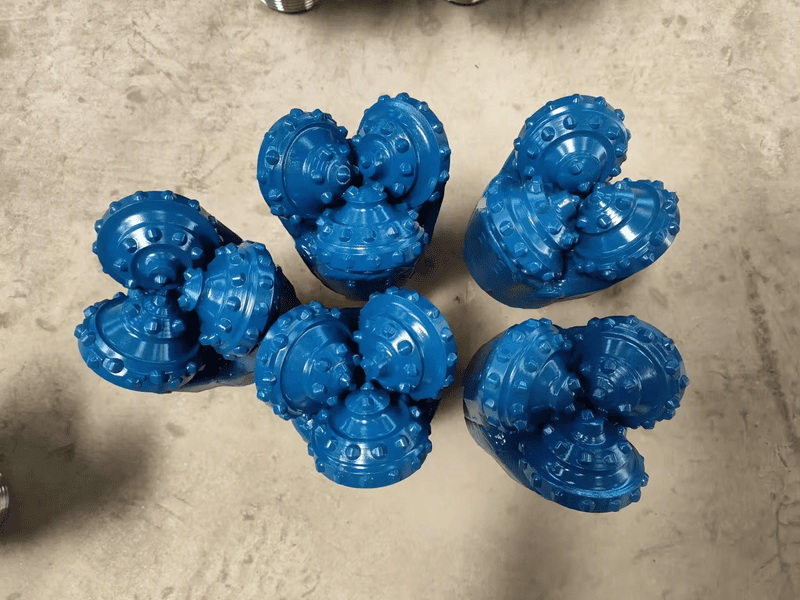

Understanding the Role of Tricone Bits

Tricone bits are designed with three rotating cones, each embedded with teeth or buttons that crush rock through a combination of rotation and pressure. This design allows them to effectively handle tough, abrasive formations that can quickly wear down other types of bits.

In these harsh environments, the robust construction of tricone bits7 ensures longevity and consistent performance, making them a reliable choice for certain drilling projects.

Comparing Performance in Varied Geological Conditions

When dealing with hard rock formations, such as granite or basalt, tricone bits offer superior performance compared to PDC bits. The rugged design of tricone bits allows them to withstand high-impact conditions, reducing the risk of damage and downtime.

Moreover, in highly variable geological scenarios, where the rock type changes frequently, tricone bits provide the versatility needed to adapt without frequent bit changes. This flexibility can significantly lower operational costs and enhance productivity.

| Factor | Tricone Bits | PDC Bits |

|---|---|---|

| Hard Rock Performance | High | Moderate |

| Abrasive Material Handling | High | Low |

| Versatility in Variable Formations | High | Moderate |

Evaluating Cost and Operational Efficiency

While PDC bits generally offer better efficiency in soft to medium-hard formations, the cost-effectiveness of tricone bits becomes apparent in challenging conditions where PDCs might require frequent replacement.

Tricone bits are often more economically viable in operations where unpredictable rock conditions necessitate frequent adaptation. This can lead to lower overall costs despite their slower penetration rates compared to PDC bits.

Strategic Decision-Making in Bit Selection

The choice between PDC and tricone bits should ultimately be driven by a comprehensive understanding of the geological landscape and project specifications. In scenarios where abrasion resistance is paramount, selecting tricone bits can lead to more effective and cost-efficient drilling operations.

Project planners must assess factors such as rock hardness, abrasiveness, and the likelihood of encountering mixed formations to determine the optimal bit choice for their specific needs. Understanding these variables ensures that drilling operations proceed smoothly and efficiently without unexpected interruptions.

Tricone bits excel in abrasive rock formations.True

Tricone bits are designed to handle tough, abrasive formations effectively.

PDC bits are more versatile than tricone bits.False

Tricone bits offer greater versatility in varied geological conditions.

Conclusion

PDC bits excel in speed, durability, and cost-efficiency, especially in consistent rock formations. For optimal drilling results, assess geological conditions carefully before choosing.

-

Discover why synthetic diamonds enhance PDC bit performance.: The disadvantage of PDC bit is that it has poor thermal stability, when the temperature exceeds 700℃, the bonding metal inside the diamond layer will fail and ... ↩

-

Learn about cost implications and savings with PDC bits.: PDC bits can achieve a higher rate of penetration than tricone bits under the right circumstances, lowering the overall cost per foot. · They ... ↩

-

Learn why PDC bits excel in stable geological conditions.: One of the main advantages of PDC bits is that they can drill faster and longer than other types of bits, such as roller cone bits or impregnated diamond bits. ↩

-

Understand the key differences between PDC and tricone bits.: Most significantly, PDC bits have a longer lifespan which means they don't need to be replaced as often as tricone bits. That reason alone ... ↩

-

Explore detailed comparisons of initial costs for informed decision-making.: Even though tricone bits may be cheaper up front, in the right kind of project that can take full advantage of the features of a PDC bit, you ... ↩

-

Learn how to conduct a thorough economic analysis for drilling operations.: Most significantly, PDC bits have a longer lifespan which means they don't need to be replaced as often as tricone bits. That reason alone ... ↩

-

Explore the unique benefits of tricone bits in challenging conditions.: PDC bits can achieve a higher rate of penetration than tricone bits under the right circumstances, lowering the overall cost per foot. They ... ↩