Ever wondered what makes Halco Rock Tools' DTH drill bits a favorite among industry pros?

Halco Rock Tools' DTH drill bits stand out for their unmatched performance and durability, thanks to meticulous engineering and premium materials. Designed to thrive in various drilling conditions, these bits are a go-to for professionals seeking efficiency and reliability.

I still remember my first project where the drill bits I initially used kept wearing out halfway through, causing endless delays. Then, a colleague recommended Halco's DTH drill bits, and they were a game-changer. Suddenly, I wasn't worrying about constant replacements or unexpected downtimes. These bits offered the reliability and efficiency I needed, especially under tough conditions. Let's explore what makes them such a standout choice in the industry.

Halco DTH drill bits are made from low-quality materials.False

Halco DTH drill bits use high-quality materials for superior durability.

Halco drill bits are suitable for diverse drilling conditions.True

These drill bits are designed to handle various conditions efficiently.

How Does Precision Engineering Impact Halco's DTH Drill Bits?

When I first encountered precision engineering, I was skeptical. Could it really transform something as robust as Halco's DTH drill bits? Turns out, it absolutely could—and did.

Precision engineering enhances Halco's DTH drill bits by utilizing advanced materials and processes for improved durability, efficiency, and customization. This ensures reliable performance across challenging drilling conditions, ultimately reducing wear and operational costs.

The Role of Material Selection

I remember the first time I learned about the role of material selection in engineering. It was like discovering a secret ingredient that changes everything. Halco uses high-quality nickel chrome alloy steel, a choice that boosts durability and wear resistance. Imagine trying to bake a cake without flour—it's just not going to work out. Similarly, using the right materials in drill bits is crucial to their performance under high-frequency impacts.

| Feature | Benefit |

|---|---|

| Nickel Chrome Alloy Steel | Increased durability and wear resistance |

These materials and processes give the drill bits the stamina they need to endure extreme drilling conditions.

Advanced Manufacturing Techniques

My appreciation for precision grew as I delved into manufacturing techniques. It's all about the details—each bit is machined to within microns for a perfect fit of carbide inserts. It’s like fitting puzzle pieces together with exact precision to ensure they stay locked in place during intense operations.

Machining to microns1 enhances integration, boosting effectiveness in hard rock formations and reducing component failure, which extends the drill bit's life.

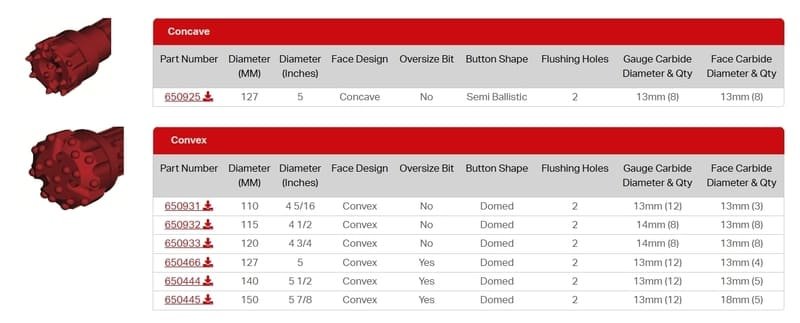

Customization for Diverse Conditions

In my journey with drilling tools, versatility has always been key. With precision engineering, Halco offers different bit head designs—flat face, concave, and convex—each suited for specific tasks. It’s akin to choosing the right tool from a toolbox; each bit head design serves its own purpose.

| Bit Head Design | Application Suitability |

|---|---|

| Flat Face | Soft to medium rock formations |

| Concave | Medium to hard rock formations |

| Convex | Hard rock formations |

These versatile design options2 optimize drilling across varied terrains, making Halco’s bits a favorite among industry pros.

Impact on Operational Efficiency

The way precision engineering bolsters operational efficiency is remarkable. Reliable performance with minimal wear means less downtime and lower maintenance costs. I've seen this in action when efficient penetration rates allow faster drilling speeds without burning through energy reserves.

For example, efficient penetration rates3 help operators speed up their work while saving energy, translating into lower costs and higher productivity. The ability of Halco's drill bits to withstand harsh conditions without degrading significantly is a game-changer, providing reliability and cost-effectiveness over extended use.

Halco uses nickel chrome alloy steel for drill bits.True

Nickel chrome alloy steel is chosen for its durability and wear resistance.

Precision engineering increases maintenance costs of Halco's bits.False

Precision engineering reduces maintenance costs by enhancing efficiency and durability.

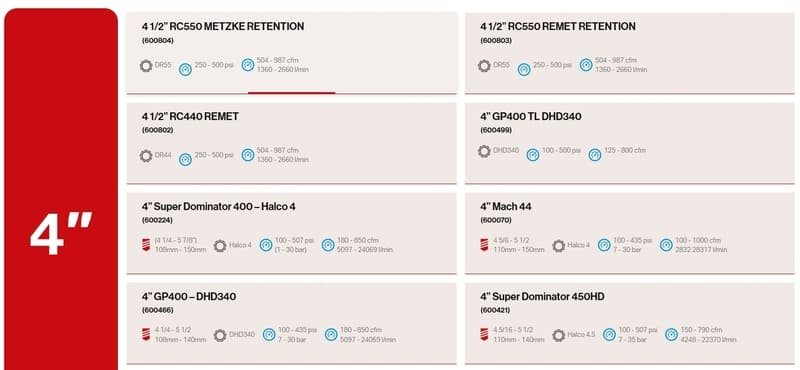

What Versatile Options Do Halco Offer for Different Drilling Conditions?

Imagine tackling any drilling challenge with ease—Halco's versatile tools make it possible!

Halco's versatile drilling solutions include various bit designs and insert types, such as flat face, concave, and convex head designs, paired with domed, ballistic, and semi-ballistic inserts, to handle different geological conditions effectively.

I remember when I first explored the world of drilling equipment and stumbled upon Halco's offerings. It was like finding a treasure trove of options tailor-made for every imaginable geological challenge.

Diverse Bit Head Designs

With Halco, I discovered that there are specific bit head designs4 for every type of rock formation:

- Flat Face: This design became my go-to for soft to medium-hard rock formations. Its stability amazed me during those tricky drills.

- Concave: I was impressed by how it improved accuracy and penetration rates in medium to hard rocks.

- Convex: For the toughest rocks, this design was unbeatable in removing cuttings efficiently.

Each design really catered to the unique geological conditions I encountered, helping me achieve optimal results without sacrificing speed or accuracy.

Multiple Insert Types

Halco's range of insert types5 allowed me to fine-tune my equipment perfectly:

| Insert Type | Applications |

|---|---|

| Domed | Suitable for hard abrasive rocks |

| Ballistic | Increases penetration rates in softer materials |

| Semi-Ballistic | Balances between hard and soft rock drilling |

This selection meant I could customize my tools to match the material hardness and abrasiveness, optimizing both performance and longevity.

Customization for Industry Needs

What really stood out to me was Halco's commitment to customization. Whether I was involved in mining, construction, or water well drilling, they offered tailored solutions. In mining, for instance, their bits handled abrasive conditions while maintaining a steady rate of penetration (ROP).

Even in geotechnical engineering projects, Halco's versatile drilling solutions6 ensured precise sampling and stable boreholes—absolutely crucial for reliable data collection.

By offering adaptable options, Halco enabled me to select the most suitable tools for my unique applications. This adaptability improved my efficiency and reduced costs associated with equipment wear and replacement. It felt like having a trusted partner that understood my needs and challenges.

Flat Face design is best for hard rock formations.False

Flat Face design is ideal for soft to medium-hard rock, not hard rock.

Ballistic inserts increase penetration in softer materials.True

Ballistic inserts are designed to enhance penetration rates in softer materials.

Why Are Halco DTH Drill Bits Ideal for Hard Rock Formations?

Ever found yourself up against stubborn, unyielding rock that just won't budge? Let me share why Halco DTH drill bits might just be the solution you need.

Halco DTH drill bits are perfect for hard rock formations because of their sturdy build and cutting-edge design. Made with top-notch materials and innovative engineering, they promise better penetration rates and longer life, making them a go-to choice for tough geological conditions.

Precision Engineering and Material Quality

I remember when I first encountered the rugged terrain that seemed impossible to penetrate. That's when I discovered Halco's exceptional use of premium nickel chrome alloy steel7. Their drill bits, with meticulous heat treatment processes, are built to withstand even the harshest conditions, much like a seasoned mountaineer tackling Everest.

Advanced Design Features

Bit Head Designs and Insert Types

Halco offers three distinct designs—Flat Face, Concave, and Convex. Imagine having a toolbox with the perfect tool for every job. These designs adapt to various drilling needs, allowing you to select the right one for specific rock densities.

| Bit Head Design | Use Case |

|---|---|

| Flat Face | Soft to medium rock |

| Concave | Medium to hard rock |

| Convex | Extremely hard rock |

Durability and Efficiency in Tough Conditions

What truly sold me on Halco was their extended bit life. I’ve seen firsthand how they reduce operational costs and downtime, much like having a reliable car that rarely needs repairs. Their innovative design boosts rate of penetration (ROP)8, achieving faster drilling while conserving energy.

Versatility Across Applications

From my own experiences in diverse projects, I can vouch for the versatility of these drill bits. They’re not just for mining; they excel in:

- Water Well Drilling: Perfect for reaching deep depths efficiently.

- Geotechnical Sampling: Offering accurate soil and rock samples.

- Quarrying: Effortlessly managing tough rock conditions.

With customization options9, Halco ensures that you can face any geological challenge head-on. Their bits are designed to work seamlessly with major drilling systems, enhancing efficiency across industries.

Halco uses nickel chrome alloy steel in their drill bits.True

Halco's drill bits are made from nickel chrome alloy steel for strength.

Convex bit heads are suitable for soft rock formations.False

Convex bit heads are designed for extremely hard rock formations.

How Do Halco DTH Drill Bits Benefit Various Industries?

Imagine drilling through solid rock with ease, thanks to the innovative Halco DTH drill bits. These bits are changing the game across industries like mining and construction, offering unmatched durability and precision.

Halco DTH drill bits transform industry operations by ensuring superior durability, precision, and efficiency. Their robust design excels in harsh environments, making them indispensable for mining, construction, and water well drilling applications.

Enhanced Performance in Mining

When I first encountered Halco DTH drill bits in a mining project, I was amazed at how they maintained high penetration rates even in tough rock conditions. These bits are crafted from nickel chrome alloy steel, which means they're not only durable but also stand the test of time—a crucial factor in mining where downtime can be costly.

| Feature | Benefit |

|---|---|

| High Penetration Rates | Faster drilling speeds |

| Durable Materials | Reduced need for replacements |

| Precision Engineering | Consistent and accurate drilling |

Versatility in Construction

In my experience with construction projects, the adaptability of Halco drill bits is a game-changer. Whether it's geotechnical sampling or foundation drilling, these bits can handle it all. The various head designs and insert types mean they can tackle different soil and rock conditions with ease, saving time and money on site.

The customization options10 Halco offers allow us to configure the bits to fit specific project needs, boosting efficiency and cutting costs.

Reliability in Water Well Drilling

During a challenging water well project, I saw firsthand how Halco DTH drill bits excel with their efficient energy transfer capabilities. This feature ensures deeper, more precise wells, which is essential when water access is on the line. Their strength is enhanced by an advanced carburization process11, making them incredibly durable.

| Application | Halco Feature |

|---|---|

| Water Well Drilling | Efficient deep hole drilling |

| Geotechnical Sampling | Accurate soil and rock samples |

These features collectively contribute to reducing operational costs and boosting productivity across various industries. Whether you're involved in mining, construction, or water well drilling, Halco DTH drill bits offer reliable performance that keeps projects moving smoothly.

Halco drill bits use nickel chrome alloy steel.True

Nickel chrome alloy steel enhances wear resistance and prolongs service life.

Halco drill bits are only used in mining.False

They are versatile, used in mining, construction, and water well drilling.

What Makes Halco Rock Tools the Go-To Choice for Drilling Equipment?

Ever wondered why Halco Rock Tools have such a loyal following in the drilling world? It’s not just about the specs—there’s a story of innovation and reliability that keeps customers coming back.

Halco Rock Tools stand out with their exceptional performance, precise engineering, and adaptability to various drilling environments. Crafted from high-quality materials and offering customizable options, they cater to diverse industrial needs, setting them apart from other brands.

Superior Performance and Longevity

Imagine working on a project where downtime isn't an option. I've been there, with pressure mounting and timelines closing in. That’s when Halco’s DTH drill bits became my go-to. These bits are crafted with nickel chrome alloy steel, offering remarkable resilience and consistency. This means fewer replacements and more time spent doing what I love—getting the job done. The precision in the carbide fitment, achieved through meticulous machining, is like having a reliable partner that doesn’t let you down.

Key Features:

- Material: Nickel chrome alloy steel

- Heat Treatment: Carburization enhances wear resistance

- Precision: Micron-level fitment of carbide inserts

Precision Engineering

Every piece of Halco equipment feels like it’s been built with the precision of a fine watch. I once compared the precision of their machining to assembling a puzzle where every piece fits perfectly, only this puzzle withstands the toughest environments. The engineering excellence is evident from their material selection to their final touches.

Engineering Highlights:

- Steel Quality: Use of high-quality nickel chrome alloy steel

- Machining Accuracy: Holes in the bit head machined for precise carbide fitment

Versatility and Customization

I’ve tackled projects that demand a unique approach—no one-size-fits-all here. Halco offers drill bit designs tailored to specific needs, like Flat Face or Convex options, which I found invaluable in varying conditions. The ability to choose from different insert types and sizes meant I could customize my tools for each challenge.

Customization Options:

- Bit Head Designs: Flat Face, Concave, Convex

- Insert Types: Domed, Ballistic, Semi-Ballistic

- Sizes: Various sizes for diverse hole requirements

Durability in Hard Rock Conditions

In the unforgiving terrains I’ve drilled, durability isn’t just a feature—it’s a necessity. Halco's bits have shown their mettle by enduring harsh impacts and still pushing through with efficient penetration rates. It’s reassuring to know you have tools designed to last.

Durability Features:

- Extended Bit Life: Reduces operational costs through longevity

- Efficient Penetration Rates: Enhances drilling speed while minimizing energy use

Versatility Across Applications

From mining to civil engineering, I’ve seen how Halco bits seamlessly adapt across industries. They’ve become a staple in my toolkit because they don’t just meet expectations—they exceed them.

| Application Areas: | Industry | Use Case |

|---|---|---|

| Mining | Surface mining in hard rock | |

| Water Well Drilling | Efficient deep hole drilling | |

| Geotechnical & Civil | Soil and rock sampling | |

| Quarrying | Tough rock formations |

Explore more about performance and longevity12 to understand how Halco maintains its edge over other brands in the market. Investigate precision engineering13 techniques employed by Halco that ensure reliable operations across varying conditions. Consider the versatility14 of Halco products to see why they're preferred in diverse industries like mining and civil construction. Dive into durability factors15 that support Halco's robust presence in demanding environments like hard rock formations. Finally, examine application adaptability16 to understand Halco's expansive use across sectors such as water well drilling and quarrying.

Incorporating these aspects, Halco Rock Tools offer a distinct advantage over competitors by meeting specific industry needs with precision, reliability, and innovation.

Halco uses nickel chrome alloy steel in their drill bits.True

Halco's DTH drill bits are made from high-quality nickel chrome alloy steel.

Halco drill bits only work in soft rock conditions.False

Halco's construction ensures durability in hard rock formations, not just soft ones.

Conclusion

Halco Rock Tools' DTH drill bits are renowned for their durability, precision engineering, and versatility, making them ideal for various drilling applications in tough geological conditions.

-

Explore how precision machining enhances drill bit durability and performance in tough environments. ↩

-

Discover how versatile designs improve drilling efficiency across various geological conditions. ↩

-

Learn about the advantages of efficient penetration rates for increasing productivity in drilling operations. ↩

-

Explore the different bit head designs offered by Halco and understand their specific applications in various geological conditions. ↩

-

Learn about the different insert types Halco offers and how each is suited for specific rock hardness levels. ↩

-

Discover how Halco customizes their drilling solutions to meet the diverse needs of various industries like mining and construction. ↩

-

Exploring this link will help you understand the unique properties that make nickel chrome alloy steel ideal for drilling tools. ↩

-

Learning about ROP will reveal how it impacts the speed and cost-effectiveness of drilling operations. ↩

-

This link will show how customization enhances the adaptability of Halco drill bits for various applications. ↩

-

Explore how customized drill bit configurations can optimize drilling efficiency and cost-effectiveness. ↩

-

Understand how carburization improves the strength and durability of drill bits for deeper drilling. ↩

-

Explore how Halco's longevity in performance reduces operational costs and enhances reliability. ↩

-

Understand the precision engineering techniques that make Halco tools reliable in varied conditions. ↩

-

See why Halco's versatile products are favored across industries like mining and civil construction. ↩

-

Discover the durability factors that support Halco's use in demanding environments. ↩

-

Examine how Halco tools adapt to various applications such as water well drilling. ↩