I really felt surprised by the DTH hammer's accuracy and strength the first time I held one. Its power was impressive. Its precision was amazing.

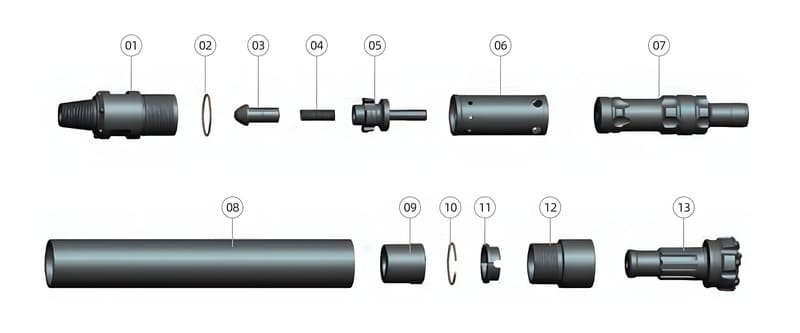

A DTH hammer has important parts such as the top sub, check valve, piston, chuck and drill bit. Every part is vital for good drilling work.

Grasping how these parts work together felt like discovering a new level in a video game. I didn’t just learn what each piece did. I also saw how they all connected to form something powerful. This deep understanding really made me appreciate more and helped me drill better.

The piston is the main moving part in a DTH hammer.True

The piston, also known as the hammer, delivers blows to the drill bit.

DTH hammers are not used in water well drilling.False

DTH hammers are commonly used for drilling water wells, especially in hard rock.

How Does Each Part of a DTH Hammer Function?

Join me as I uncover the secrets of a DTH hammer. This tool is an unsung hero in deep rock drilling. Each part fits like a puzzle piece.

A DTH hammer consists of several important parts. The top sub, check valve, cylinder, piston, chuck and drill bit are key components. The outer case, exhaust ports, compression chamber and O-rings are also included. Each part is vital. They direct energy from above the ground to the drill bit. This energy helps to break through rock.

Top Sub (Adapter)

The top sub is a crucial link between the hammer and the drill string. It works like a reliable step on a ladder, handling great stress as it sends rotation down to the hammer. A skilled driller once told me that a good top sub is as vital as sturdy boots on rough ground. Understanding the material quality of the top sub can be crucial for optimizing drill performance1.

Check Valve

The check valve fits inside the top sub, stopping water or air from moving back up the drill string when at rest. It keeps pressure intact for smooth energy delivery to the drill bit. A failing check valve is like discovering a leaky umbrella in the rain. This is vital for maintaining pressure integrity and ensuring efficient energy transfer to the drill bit.

Cylinder

The cylinder holds and guides the piston with accuracy. It is like managing traffic to keep everything moving well. The material and design matter a lot because these decide how it manages drilling conditions. My friend stressed this when she picked strong materials for her kitchen, just like for a cylinder. The design and material of the cylinder affect its durability and performance under various drilling conditions, making it essential to choose suitable materials2.

Piston (Hammer)

The piston is the heart of the hammer, converting air to strong force. It acts like a drummer in a band, needing perfect timing and power to cut through rock. Drilling speed and efficiency rely on its steady, strong beats.

Chuck (Bit Retainer)

The chuck grips the drill bit, letting it spin while transmitting force from hammer to bit. It functions like my dependable wrench, which is always ready for repairs, ensuring everything works well.

Drill Bit

On the frontline, the drill bit tackles rock formations with bravery. It has buttons designed for different rock types. Picking the right drill bit is like choosing perfect shoes for a hike; it greatly impacts performance.

Outer Case (Housing)

The outer case acts like a strong backpack. It protects inner parts and controls air release after the piston strikes. It must withstand harsh conditions similar to how my backpack saved me from rain.

Exhaust Ports

Exhaust ports let used air exit efficiently after moving the piston. They are like kitchen windows that release steam after cooking - essential for keeping the system well-regulated.

Compression Chamber

This chamber holds compressed air briefly before it powers the piston. Its design affects how energy spreads much like a coffee thermos keeps your drink hot until needed.

O-rings and Bushings

These small parts seal joints and cut down friction between moving elements. They are akin to small items that ease life at home such as rubber bands keeping order or oil calming a squeaky door.

DTH hammers are used for drilling in soft soil.False

DTH hammers are designed for hard rock formations, not soft soil.

The piston is a key component of a DTH hammer.True

The piston, or hammer, drives the drill bit into the rock.

Why is Maintenance of DTH Hammer Components Crucial?

Have you ever thought about why a little hard work changes everything in the world of DTH hammers?

Maintaining DTH hammer parts is crucial. This helps them work well, reduces stoppages and prolongs their lifespan. If not properly cared for, these tools may fail. Breakdowns can happen suddenly, messing up schedules and raising expenses. Regular inspections of pistons, drill bits and O-rings are very important. These checks keep operations smooth.

Understanding the Key Parts

I remember the first time I held a DTH hammer. I was amazed by its complexity. Every part—like the piston, drill bit, or chuck—has a vital job. The check valve3 directs the piston, keeping timing precise. The top sub links everything to the drill string. Together, these parts turn air energy into impact energy. This energy is what helps us drill efficiently.

Effects on Performance

A small problem with one part can disrupt everything. Picture this: you’re on a project with tight deadlines, then a worn-out piston4 cuts your impact power. I faced this issue once. Those added drilling hours raised costs and messed up my schedule. Damaged O-rings are also troublemakers; they seem minor, but air leaks lower your tool’s power.

Avoiding Expensive Delays

I recall a tough day when sudden equipment failure stopped all work. The reason? Skipped maintenance. Now, I strongly support regular checks and replacing parts like the cylinder on time. This proactive care saves me many problems and ensures smooth projects without pauses.

Tips for Maintenance

Proper lubrication5 is crucial as it reduces friction and helps parts last longer. Another piece of advice? Look for debris in exhaust ports; ignoring it lowers performance. I also keep a detailed maintenance log which helps track part lifespan and plan replacements early.

Equipment Longevity

Routine care is not just for today's work; it keeps equipment healthy long-term. I’ve noticed how this cuts the need for new tools, increases returns on investment, and significantly reduces our environmental impact by minimizing manufacturing and disposal needs.

DTH hammers are used only in mining.False

DTH hammers are used in mining, construction, and water well drilling.

Proper maintenance extends DTH hammer life.True

Regular maintenance prevents wear and damage, extending equipment lifespan.

What Are the Common Issues with DTH Hammer Parts?

Have you ever felt your drilling work stops due to machine problems? You are not alone!

Frequent problems with DTH hammer parts often include wear on the piston, air leaking from damaged O-rings and blocked exhaust ports. Regular care fixes these issues. It keeps your drilling work very efficient. It keeps your operations running well.

Wear and Tear on the Piston

The piston in a DTH hammer works like the heart of your machine. It keeps everything going. Over time, the constant pressure and motion cause it to wear down. I once noticed a big drop in efficiency during a tough drilling job. A quick check showed the piston was worn out. Regular checks6 are important to find these problems early. If you ignore it, efficiency goes down, and other parts may also suffer damage.

Air Leaks from Damaged O-rings

O-rings, though small, play a big role in sealing parts. They keep air from leaking out of the hammer. I once lost a lot of pressure due to bad O-rings. Replacing them during routine maintenance can be crucial. It’s important to use O-rings that fit your hammer’s specifications to avoid any potential fitment issues.

Clogging in Exhaust Ports

Exhaust ports let debris and air escape during drilling. When they clog, it feels like breathing through a straw. I now always clean these ports with compressed air7. This simple task keeps everything moving smoothly and stops unwanted pressure from building up.

Wear on the Drill Bit and Chuck

The drill bit and chuck face a lot of impact and friction, leading to wear over time. For me, using high-quality materials is a game-changer. Rotating the drill bit is a small yet effective habit that extends the lifespan of these parts.

Check Valve Malfunction

The check valve is key for keeping pressure inside the hammer. Once, I dealt with inconsistent pressure issues due to a faulty check valve. Regular checks help catch such problems early, allowing for prompt replacement before larger issues arise.

By knowing these common problems and doing regular maintenance, my equipment lasts longer, ensuring my projects run smoothly and efficiently. Being proactive helps keep everything in top condition.

DTH hammers are used only in mining.False

DTH hammers are used in mining, construction, and water well drilling.

Piston is a part of the DTH hammer.True

The piston, also known as the hammer, is crucial for drilling action.

How Can I Choose the Right DTH Hammer for My Project?

Choosing the best DTH hammer resembles selecting the right tool from a toolbox. This choice is crucial. A good DTH hammer is vital for completing the task correctly.

Picking the correct DTH hammer means knowing your project's hole size, type of rock, air pressure needs and final goals. The hammer's details must match your drilling needs. This is really important. It saves money and time.

Know Your Project Details

When starting on drilling tasks, understanding every part of the project is very important. It is like planning a trip; you need to know where you are going. Determine the borehole's size and depth, as these factors will significantly influence your choice. Different projects, whether in mining or construction8, require varying hammer types.

Check Rock Formations

I once thought a rock was softer than it was. It felt like using a feather to crack a nut. Tough rocks demand strong hammers with high power. Softer rocks are easy with lighter tools. Conducting a geological survey can provide insights into rock hardness, helping you select an appropriate hammer.

Think About Air Pressure

Air pressure keeps everything running smoothly. Wrong air pressure makes the work difficult and tiring. Ensure your air compressor can deliver sufficient pressure to match the hammer's requirements. Follow the manufacturer's guidelines for air pressure specifications to ensure compatibility with your selected DTH hammer9.

Match with Drill Bits

The hammer and drill bits must fit well together. Some hammers need specific bits. Always check sizes and connections to prevent problems during operations.

Look at Manufacturer Advice and Reviews

Before buying new equipment, I read through forums and reviews. Manufacturer advice is helpful, but real user feedback is invaluable. Consult manufacturer guidelines and explore forums for real-world feedback on specific models, which can inform your decision-making process.

By considering these tips, I pick a DTH hammer that fits my projects perfectly, avoiding costly errors.

DTH hammers are used only in construction.False

DTH hammers are used in mining, construction, and water well drilling.

Pistons in DTH hammers are also called hammers.True

The piston is commonly referred to as the hammer in DTH systems.

What Innovations Are Shaping the Future of DTH Hammers?

Have you ever thought about how DTH hammers are changing drilling? Let's explore the new ideas that bring these changes.

Innovations are changing DTH hammers. Advanced materials, smart technology and eco-friendly designs are really making a difference. Efficiency is improving. Sustainability is also getting better.

Advanced Materials for DTH Hammers

I recall learning how new materials change industries. One of the key innovations in DTH hammers is the development of advanced materials10 that enhance durability and performance. Manufacturers are now using composite materials and high-strength alloys to improve wear resistance, reduce weight, and increase the lifespan of hammer components. This change is vital as it not only improves drilling efficiency but also lowers operational costs by reducing the frequency of part replacements. The result is less need for replacements and lower costs—a big plus is not worrying about worn-out parts during an important project. What a relief!

Integration of Smart Technology

Technology fascinates me. It often surprises me with how it can simplify work. The integration of smart technology into DTH hammers is another major advancement. Modern hammers are equipped with sensors and IoT capabilities that allow operators to monitor performance in real time. This data-driven approach enables predictive maintenance, reducing downtime and increasing productivity. Remote operation control is like a secret advantage for tricky drill spots—remote operation11 is particularly beneficial in hazardous or hard-to-reach environments.

Eco-Friendly Designs

I am very excited about inventions that help make our world greener. As industries move towards sustainability, eco-friendly designs in DTH hammers are exciting examples evolving to minimize environmental impact. Innovations include the development of energy-efficient models that use less power and emit fewer pollutants. Additionally, some manufacturers are experimenting with biodegradable lubricants and alternative fuels to further reduce the ecological footprint of drilling operations. This means our drilling can be powerful and kind to the planet—a truly great match!

Enhanced Drill Bit Technology

The impact of a small drill bit is surprising; new drill bit technology is really impressive. The performance of a DTH hammer is closely linked to its drill bit technology. Recent advancements have led to the creation of bits with enhanced cutting edges12 and coatings that improve penetration rates and reduce wear, helping bits cut deeper and last longer. These improvements not only boost efficiency but also extend the life of both the hammer and the bit, leading to significant cost savings over time.

Understanding these changes helps us choose new methods that fit our operational and environmental goals. By understanding these innovations, stakeholders can make informed decisions about implementing new technologies that align with their operational goals and environmental commitments—it's a thrilling moment to join industries using DTH hammers!

DTH hammers are only used in mining.False

DTH hammers are used in mining, construction, and water well drilling.

Piston is a crucial part of DTH hammer.True

The piston impacts the drill bit for efficient drilling in hard rock.

What Makes DTH Hammers Stand Out from Other Drilling Technologies?

Do you think about why DTH hammers are special in drilling? Let's explore why they could be ideal for your important project.

DTH hammers excel in deep drilling. They work well in tough rock. Precision and quieter noise are their benefits. They cost more at the start. In hard rock conditions, they create straight holes. These tools last long. They offer less efficiency in softer ground.

Precision and Control

I remember my first big drilling job where precision was key. We were drilling in a tough spot, so keeping the hole straight mattered a lot. DTH hammers excelled here. Placing the hammer just behind the drill bit gave us great accuracy and reduced wandering. Top hammer drilling13 often loses its way because the force moves down the drill string.

Efficiency in Hard Rock

Once, we faced a really hard rock layer. It felt like trying to break a concrete wall. But DTH hammers hit hard directly at the bit, so tough rock became possible to handle. Rotary drilling14 goes well in soft soil, but with hard rock, it’s like using a spoon instead of a knife.

Cost and Longevity

At first, the price of DTH hammer systems looked high. It seemed like a big cost upfront. Over time, I saw they last longer and need fewer fixes. It’s like good shoes: costly first, but they outlast the cheaper ones. Remember this when checking costs - you save more later by considering both upfront expenses15 and long-term savings.

Noise and Environmental Impact

I didn’t think much about noise until we worked near homes. I didn’t want to bother families with noise. DTH hammers are quieter as sound stays in the borehole, making them suitable for places where less noise is important.

Versatility Across Rock Types

I prefer DTH hammers for hard rock, but they aren’t always best for soft or loose rocks. Mud rotary drilling16 works better there. Choosing the right tool helps as rock type changes how successful and efficient drilling becomes.

DTH hammers are more efficient in hard rock formations.True

DTH hammers are designed for efficient drilling in hard rock.

Top hammer drilling is quieter than DTH drilling.False

DTH drilling is generally quieter due to its deeper impact point.

Conclusion

A DTH hammer consists of essential components like the piston, drill bit, and check valve, crucial for efficient drilling in hard rock formations across mining and construction industries.

-

Learn how material choice enhances drill performance. ↩

-

Identify materials that improve durability and performance. ↩

-

Learn how the check valve maintains optimal piston movement. ↩

-

Identify symptoms of piston wear to avoid inefficiencies. ↩

-

Discover effective lubrication methods to reduce wear. ↩

-

Learn inspection techniques for identifying piston wear early. ↩

-

Explore methods for efficiently clearing clogged exhaust ports. ↩

-

Discover specific DTH hammers suitable for mining versus construction projects. ↩

-

Learn essential tips for selecting a DTH hammer efficiently. ↩

-

Explore how new materials boost DTH hammer durability. ↩

-

Learn how remote operation enhances safety and efficiency. ↩

-

Discover cutting-edge bit technologies improving drilling outcomes. ↩

-

Discover how top hammer drilling handles different depths and formations. ↩

-

Learn why rotary drilling excels in softer geological conditions. ↩

-

Explore detailed cost analysis for informed financial decisions. ↩

-

Find out how mud rotary drilling performs in soft terrains. ↩