Have you ever wondered why Epiroc DTH drill bits are the go-to choice for drilling experts?

Epiroc DTH drill bits are beloved for their robustness, cutting-edge design, and exceptional efficiency, making them perfect for tough drilling tasks. Built with top-grade materials like alloy steel and tungsten carbide, they promise a longer lifespan and superior energy release, enhancing productivity in mining and construction.

Remember when I was knee-deep in a project, and I needed reliable equipment that wouldn't let me down? That's when I discovered the remarkable benefits of Epiroc DTH drill bits. These tools go beyond basic features, with advanced technology and user-friendly designs that truly shine in real-world applications. Let's explore how these attributes make a difference in demanding drilling environments.

Epiroc DTH drill bits use tungsten carbide.True

Tungsten carbide is used for its durability and efficiency in drilling.

Epiroc DTH drill bits lack innovative design features.False

They are known for their innovative design, enhancing performance.

How do design innovations enhance Epiroc DTH drill bits?

Have you ever watched a craftsman at work and been amazed by the precision of their tools? That's how I feel about Epiroc's DTH drill bits.

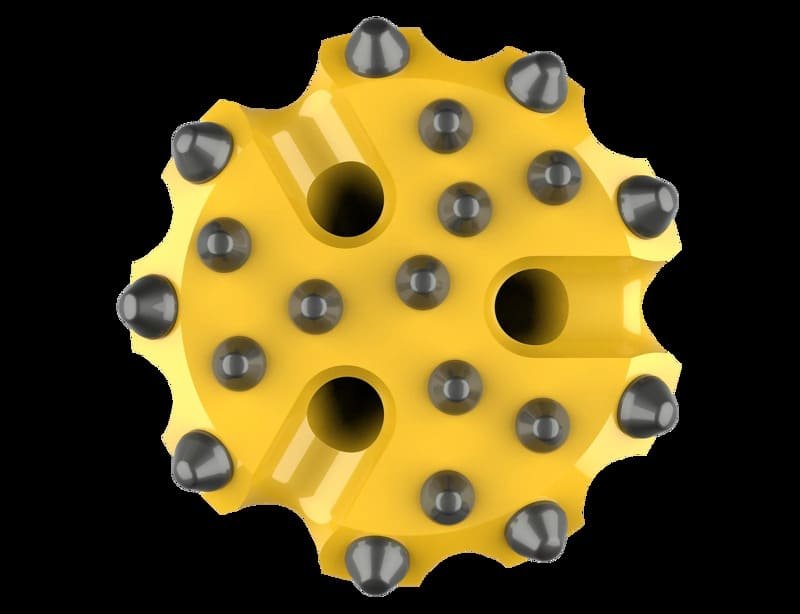

Epiroc DTH drill bits are revolutionized by design innovations that boost durability, speed, and energy efficiency. Key updates include optimized flushing design, enhanced carbide materials, and more buttons for better energy transfer.

Innovative Material Use

Epiroc uses top-notch materials in their DTH drill bits1. High-quality tungsten carbide is like the superhero of materials, fighting wear and tear with ease. It reminds me of those times when you find a tool so reliable, it becomes your go-to. Plus, the premium alloy steel adds an extra layer of durability, translating into fewer replacements and noticeable cost savings—definitely a win-win.

Optimized Button Design

The design team at Epiroc has really hit the nail on the head (or the button, in this case) by increasing the number of buttons on the bit face. It’s like adding extra horsepower to a sports car. This change means faster drilling and more meters per shift—essentially more bang for your buck.

| Feature | Benefit |

|---|---|

| More Buttons | Increased energy transfer |

| Advanced Carbide | Reduced wear and tear |

Enhanced Flushing Design

I always hated it when our operations stalled because of blockages. Epiroc’s flushing design has been fine-tuned to tackle this issue head-on, ensuring smooth sailing—or should I say, smooth drilling? This efficiency is crucial for projects where every minute counts.

Check out more on flushing designs2 to see their impact on performance.

Heat Treatment and Hardness Improvements

Heat treatment isn't just for blacksmiths; it's a game-changer for drill bits too. Epiroc has amped up this process, increasing face hardness to withstand the toughest conditions. I’ve seen firsthand how important this balance of strength and toughness is when every bit needs to stand up to stress without faltering.

Find out how heat treatment impacts3 material properties in industrial settings.

Versatility and Customization Options

One size doesn't fit all in drilling, and Epiroc gets that. Whether it's hard rock or softer formations, there's a tailored solution available. This customization makes all the difference in diverse conditions, reminding me of how vital it is to have the right tool for each unique challenge.

| Customization Option | Application Suitability |

|---|---|

| Trubbnos Buttons | Hard and abrasive formations |

| Multiple Sizes | Different geological conditions |

Epiroc uses tungsten carbide in DTH drill bits.True

Tungsten carbide reduces wear, extending the lifespan of drill bits.

More buttons on Epiroc bits slow down drilling speed.False

Increased button numbers enhance energy transfer, speeding up drilling.

Why is durability a key factor for Epiroc's popularity?

Ever wondered why Epiroc's equipment stands the test of time in the drilling industry? It's all about durability! Here's why that matters so much.

Durability is vital for Epiroc's popularity because it ensures longer equipment life, reduces operational costs, and enhances performance even in harsh environments. This reliability has cemented Epiroc's reputation as a trusted name in the drilling and mining industries.

Performance and Longevity

I remember the first time I saw Epiroc's drill bits4 in action. It was during a project out in some of the toughest terrains imaginable. These bits are designed to last longer, often surpassing the lifespan of their competitors. This isn't just marketing fluff—it's thanks to the premium materials like alloy steel and tungsten carbide they use, which are heat-treated to take on extreme conditions.

| Feature | Epiroc's Advantage |

|---|---|

| Material | Premium alloy steel and tungsten carbide |

| Longevity | Often surpasses competitors' lifespan |

| Strength | Heat treated for optimal toughness |

Innovative Design Features

What truly sets Epiroc apart are the innovative design5 features. I once spoke with a long-time operator who couldn't stop raving about how the extra buttons on the bit face made drilling feel almost effortless. This design not only boosts energy release during drilling but also makes flushing more efficient, keeping wear and tear to a minimum.

Versatility Across Applications

Another reason I believe Epiroc leads the pack is their ability to adapt to diverse drilling conditions. From my experience, whether you're tackling dense rock or softer materials, there's an Epiroc product for every challenge. They offer various button options and sizes up to 48 inches in diameter, allowing you to choose tools that maximize durability under specific conditions.

| Application | Customization Options |

|---|---|

| Button Types | Various options |

| Diameter Range | Up to 48 inches |

Enhanced Productivity

It's amazing how a durable design can boost productivity. Imagine cutting down on interruptions simply because your equipment lasts longer. I've seen firsthand how this translates into more meters drilled per shift and significantly less downtime for maintenance.

Operator Benefits

The benefits don't stop at efficiency. Durable equipment also means safer operations—fewer replacements lead to less manual handling, which reduces injury risks. Knowing that your gear will hold up gives operators like us peace of mind and the confidence to focus on getting the job done.

By prioritizing durability, Epiroc ensures their products meet high expectations for performance and reliability, making them a go-to choice in industries where operational efficiency is not just important—it's essential.

Epiroc's drill bits last 20% longer than competitors'.True

Epiroc's use of premium materials and design extends product lifespan.

Epiroc offers drill bits up to 60 inches in diameter.False

Epiroc provides drill bit sizes up to 48 inches, not 60 inches.

How Do Epiroc DTH Drill Bits Improve Efficiency and Productivity?

Let me take you back to a moment when everything clicked, thanks to Epiroc's DTH drill bits.

Epiroc DTH drill bits boost efficiency and productivity with their exceptional performance, cutting-edge design, and adaptability. These bits deliver faster drilling speeds, longer lifespan, and minimized downtime, making them perfect for tough tasks.

I remember standing on a dusty construction site, the sun blazing down, as we struggled to meet our drilling targets with outdated tools. It was then that I discovered Epiroc DTH drill bits. These bits aren't just tools; they're game-changers. With superior materials like alloy steel and tungsten carbide, they not only endure the harshest conditions but thrive in them.

Superior Performance and Longevity

Epiroc DTH drill bits are crafted from premium materials that make them tough as nails. The first time I saw one in action, it was like watching a master craftsman at work—precision and durability working in harmony. They last up to 20% longer than their predecessors because of their robust construction, which means less downtime and more time getting the job done.

| Feature | Benefit |

|---|---|

| Alloy Steel & Tungsten Carbide | Increased durability |

| Heat Treatment | Enhanced toughness |

| Shot Peening | Improved strength |

Innovative Design Features

What truly sets Epiroc apart is their innovative design. More buttons on the bit face increase energy release during drilling, while the new carbide material reduces wear and tear. Picture this: a sleek, finely-tuned sports car, except it's a drill bit eating through rock with ease. The optimized flushing design ensures that debris is efficiently cleared away, maintaining high-speed penetration rates.

These elements contribute to faster drilling speeds6 and improved penetration rates.

Versatility and Customization

One size does not fit all, and Epiroc gets that. They offer a range of options to suit different needs—from traditional to Trubbnos buttons—and sizes up to a 48" head diameter. Whether you're tackling hard rock or softer soils, there's a bit that fits your needs perfectly.

- Multiple Button Options: Cater to specific geological formations.

- Wide Size Range: Accommodates various drilling needs.

Operator Benefits

For those of us on the ground, fewer interruptions mean more focus on the task at hand. With Epiroc DTH drill bits, we experience longer periods of undisturbed drilling. This isn't just about efficiency; it's about safety too. Less manual handling translates to fewer risks of injuries from lifting or dropping bits.

- Reduced Downtime: Less frequent bit changes.

- Enhanced Safety: Minimizes manual handling risks.

These features collectively make Epiroc DTH drill bits indispensable in boosting operational efficiency and productivity. They tackle common challenges head-on, offering both performance and peace of mind in the field.

Epiroc DTH bits last 20% longer than previous models.True

Crafted from premium materials, they are more durable.

Epiroc DTH bits have fewer buttons on the bit face.False

They have more buttons for increased energy release.

What Makes Epiroc Drill Bits a Game-Changer for Operators?

Imagine being in the thick of a drilling operation, knowing you've got a tool that won't just keep up but will outlast your expectations.

Epiroc drill bits provide operators with enhanced durability, innovative design, and increased efficiency, leading to fewer interruptions and improved safety. These features translate into higher productivity and lower operational costs.

Enhanced Durability

Let me tell you, there's nothing quite like the peace of mind that comes with using tools you can rely on. Epiroc drill bits are crafted from premium alloy steel and high-quality tungsten carbide, making them tough as nails. I remember the first time I switched to Epiroc; those bits lasted up to 20% longer than anything else I'd used. They're heat-treated and shot peened to perfection, ensuring they're ready for the toughest jobs.

- Material: Premium alloy steel & tungsten carbide

- Processing: Heat treated & shot peened

For more details on their durability, see advanced heat treatment7.

Innovative Design Features

The design is where Epiroc really shines. With more buttons on the bit face, these tools release energy more efficiently during drilling. I once found myself in a tight spot with a tricky rock formation, and those extra buttons made all the difference. Plus, the new carbide material reduces wear, which means I spend less time changing bits and more time getting the job done.

| Feature | Benefit |

|---|---|

| More bit face buttons | Increased energy release |

| New carbide material | Reduced wear |

| Optimized flushing | Efficient drill cutting disposal |

For more detailed insights on these features, refer to innovative design features8.

Improved Efficiency and Safety

Efficiency is key in this line of work, and Epiroc drill bits deliver with faster speeds and better penetration rates. On one project, we hit our targets ahead of schedule because we weren't constantly pausing for bit changes. This not only boosted productivity but also minimized manual handling risks, which is a huge plus for safety.

- Fewer interruptions: More undisturbed drilling periods

- Safety: Reduced risk of injuries from manual handling

For a complete overview of how Epiroc improves operator safety, see improved working conditions9.

Epiroc drill bits last 20% longer than older models.True

Epiroc drill bits are made from premium materials and undergo advanced treatment.

The new carbide material increases bit wear.False

The new carbide material actually reduces wear, enhancing durability.

Conclusion

Epiroc DTH drill bits are favored for their durability, innovative design, and efficiency, enhancing productivity in tough drilling tasks with longer lifespans and reduced downtime.

-

Learn how high-quality materials contribute to the longevity and effectiveness of drill bits. ↩

-

Understand how flushing designs improve debris removal during drilling operations. ↩

-

Explore the benefits of heat treatment in enhancing drill bit toughness and durability. ↩

-

Learn about the materials that give Epiroc drill bits their durability and how these contribute to extended equipment life. ↩

-

Explore how Epiroc's design innovations improve equipment lifespan and operational efficiency in challenging conditions. ↩

-

Exploring the design features responsible for speed improvements highlights their engineering excellence. ↩

-

Discover how Epiroc's advanced heat treatment enhances the strength and durability of their drill bits. ↩

-

Learn about the innovative design elements that make Epiroc drill bits stand out in the market. ↩

-

Explore how Epiroc's designs reduce risks and improve safety for operators. ↩