Picture yourself working in the heart of a bustling city, drilling away without disturbing the serenity around you. This is where DTH drilling shines.

DTH drilling is quieter because its percussion mechanism operates underground at the drill bit, minimizing surface noise. The earth absorbs much of this sound, making it perfect for urban settings.

Remember when I first learned about DTH drilling's quieter nature? It was a game-changer for projects in noise-sensitive areas. Unlike other methods where noise reverberates through steel rods at the surface, DTH keeps the action underground. Exploring its technical components and comparing them with other techniques revealed just how ideal DTH is for urban projects. It's not just about quieter operations; it's about efficiency and respect for the surrounding environment.

DTH drilling reduces surface noise significantly.True

The percussion mechanism works underground, minimizing surface noise.

DTH drilling is louder than rotary drilling methods.False

DTH is quieter due to its underground percussion mechanism.

How Does Hammer Location Affect Noise Levels?

Ever wondered why some drilling setups are noisier than others? It's not just about the equipment but where that hammer's doing its work.

The hammer's location plays a huge role in noise levels during drilling. In Down-the-Hole (DTH) systems, the hammer is at the drill bit, using the earth as a natural sound buffer, which keeps surface noise to a minimum. Conversely, top hammer systems are noisier since they operate closer to the surface.

Hammer Action: Surface vs. Underground

Imagine you're at a construction site, and the difference in noise between a Down-the-Hole1 (DTH) and a top hammer system is like night and day. I remember when I first learned about this while working on a project near a residential area. The DTH system was our savior because it kept the neighbors happy and unbothered. With DTH, the hammer operates directly at the drill bit underground, using the earth to muffle the noise naturally. On the other hand, top hammer systems create a racket since their percussion happens above ground.

Noise Reduction Techniques

Natural Sound Barrier

I once had to explain to a skeptical project manager how the surrounding rock and soil act like a giant pair of earmuffs for DTH systems. It was during a meeting where we were brainstorming ways to reduce noise complaints from nearby residents. The ground absorbs much of the sound waves produced by the hammering action, significantly cutting down noise pollution at the surface.

Surface Equipment Noise

Another point of relief is that DTH setups involve quieter surface components like rotation and feed mechanisms. I’ve seen firsthand how this can make a world of difference compared to top hammer systems, where the surface equipment adds to the noise with every percussion.

| Drilling Method | Hammer Location | Noise Level at Surface |

|---|---|---|

| Top Hammer | Surface | High |

| Down-the-Hole (DTH) | Underground | Low |

Impact on Sensitive Environments

Working in urban or environmentally sensitive areas requires a gentle approach—trust me, I’ve been there. The quiet operation of DTH drilling is perfect for minimizing disruptions to both people and wildlife. I’ll never forget the relief on a client’s face when they realized they wouldn’t have to deal with angry neighbors.

Advanced Noise-Dampening Technologies

Modern DTH rigs are like the luxury cars of drilling—quiet and smooth. They often come equipped with sound-dampening technologies2, such as enclosures for noisy components and low-noise engines. During one particularly tricky project, these advancements were key in keeping our operations under the local noise regulation radar.

In short, understanding how different drilling techniques impact noise levels can make or break a project’s success, especially in sensitive environments. By choosing the right equipment and employing strategic planning, you can effectively manage noise and keep everyone—from nearby residents to wildlife—happy.

DTH drilling reduces surface noise using natural barriers.True

DTH systems use surrounding ground as an acoustic barrier, lowering noise.

Top hammer drilling is quieter than DTH drilling.False

Top hammer systems generate more surface noise than DTH systems.

How Does Surface Equipment Help Reduce Noise?

Ever wondered how drilling can be less of a noise fest? Surface equipment is the unsung hero in making operations quieter, keeping both the peace and compliance intact.

Surface equipment reduces noise through quieter technologies, efficient energy transfer, and sound-dampening systems. These innovations are crucial for minimizing noise pollution, especially in urban and sensitive environments.

Quieter Technologies in Surface Equipment

Have you ever been startled by the deafening roar of industrial machinery? I remember the first time I stood near a traditional diesel engine—my ears were ringing for hours! Modern surface equipment, however, uses quieter technologies. Imagine electric motors3 humming softly compared to those old beasts. The switch to hydraulic systems for rotational and feed mechanisms further hushes the operational noise.

Efficient Energy Transfer

When I first learned about DTH drilling4, it was like discovering a secret trick to peace and quiet. The direct energy transfer means less energy wasted as noise. Picture this: dampers act like shock absorbers, soaking up vibrations before they have a chance to turn into that familiar racket.

Advanced Sound-Dampening Systems

I’ve seen some rigs equipped with advanced damping systems that are akin to wrapping a noisy gift in a soundproof box. Enclosures made from sound-absorbing materials5 trap and dissipate sound waves, making everything quieter. It’s like the difference between playing drums in an open room versus inside a padded studio.

Noise-Reducing Features in Equipment Design

You know how you can instantly tell when a car has insulated windows or a plush interior? Well, surface equipment is no different with its noise-reducing designs. From insulated cabs to noise barriers6 and vibration isolators, these features create a more serene environment both inside and out. Here’s how they work:

| Feature | Function | Effect on Noise |

|---|---|---|

| Insulated Cabs | Reduce operator exposure | Decrease internal noise |

| Noise Barriers | Block sound paths | Lower external noise |

| Vibration Isolators | Minimize vibration transfer | Reduce structural noise |

Impact of Surface Equipment on Urban Environments

I once heard from a friend who worked on an urban project where the proximity to residential areas meant that keeping noise down wasn’t just a preference—it was a necessity. Imagine trying to drill without waking up the entire neighborhood! Surface equipment that cuts down on sound is essential for staying on good terms with local residents and complying with strict regulations.

Role of Maintenance in Sustaining Noise Reduction

It’s like how your car suddenly sounds louder when it’s overdue for service—surface equipment is no different. Regular maintenance ensures everything runs smoothly and quietly. A routine check-up can catch worn-out parts before they start contributing to unwanted noise levels.

Understanding these elements helps in choosing and using surface equipment that balances operational efficiency with environmental responsibility. By embracing quieter technologies and sound-dampening features, companies can significantly lessen the impact of their operations on surrounding areas.

Electric motors in surface equipment are noisier than diesel engines.False

Electric motors are generally quieter than traditional diesel engines.

Noise barriers in equipment design block sound paths effectively.True

Noise barriers are designed to block sound paths, reducing external noise.

How Does Direct Energy Transfer Minimize Vibrations?

Ever wondered why some systems hum along quietly while others shake and rattle? It all comes down to how energy is transferred.

Direct energy transfer reduces vibrations by precisely channeling energy to its target, minimizing loss through sound and heat. This ensures smoother operations, quieter environments, and less wear on equipment components.

Energy Transfer Mechanisms

I remember the first time I saw a Down-the-Hole (DTH) drilling operation in action. It was fascinating how the hammer worked directly at the drill bit. This precision of energy delivery really caught my attention because it showed how important it is to minimize energy loss through intermediary systems7, ensuring efficient force application right where it's needed most.

Vibration Control in Engineering

In my line of work, I've seen firsthand how crucial reducing vibrations is—whether it's in machinery or structural design. Using direct energy transfer mechanisms can be a game-changer, cutting down the oscillations that often lead to excessive wear and noise. This not only extends system longevity8 but also makes for a much more pleasant working environment.

| Method | Benefits |

|---|---|

| Direct Energy Transfer | Less vibration, efficient force application |

| Indirect Transfer | Increased wear, higher noise levels |

Practical Applications

Take construction and mining, for example. I've observed how direct energy transfer technology in modern drilling equipment9 leads to deeper penetration with minimal vibration. This results in smoother operation10, enhancing both performance and safety by reducing the risk of equipment failure.

Role of Material Design

Over the years, I've come to appreciate how materials that naturally dampen vibrations can significantly boost the effectiveness of direct energy transfer systems. Integrating such materials is key for creating innovative solutions11 that reduce noise and prolong equipment life.

Direct energy transfer reduces machinery wear.True

Direct energy transfer minimizes vibrations, leading to less wear on machinery.

Indirect energy transfer improves drilling efficiency.False

Indirect energy transfer leads to increased vibrations and inefficiency in drilling.

How does continuous drilling enhance quiet operations?

Imagine working on a drilling site, surrounded by the usual noise, when suddenly, everything becomes quieter. That’s the magic of continuous drilling techniques.

Continuous drilling enhances quiet operations by efficiently transferring energy to minimize surface noise and vibrations. This uninterrupted process helps reduce noise spikes, making it perfect for sensitive environments.

Reduced Surface Equipment Noise

When I first encountered Down-the-Hole (DTH)12 technology, it was a game-changer. Picture the hammer working right at the bottom of the hole—no more loud, jarring sounds reaching the surface. The earth itself absorbs these noises, which is a huge relief, especially in urban areas where every decibel counts.

| Equipment | Noise Level Reduction |

|---|---|

| Top Hammer | Moderate |

| DTH | Significant |

Efficient Energy Transfer

The beauty of continuous drilling is in its efficient energy use. I remember a project where this efficiency meant not just quieter operations but also better performance. More energy was breaking rock instead of turning into noise, which was a win-win for both the project and the nearby community. This approach significantly cuts down on vibrations that travel to the surface, making everything feel smoother and less intrusive.

Vibration Management

Think about driving on a highway versus a bumpy road. Continuous drilling is like that smooth highway ride—no sudden stops or starts to jolt you awake. This consistency means fewer noise spikes and less vibration, which was especially appreciated on a job where advanced damping systems helped us keep things even quieter.

Depth and Noise Reduction

For deeper projects, continuous drilling truly shines. The deeper we drilled, the more isolated the noise became, thanks to the ground acting as a natural sound barrier. In one city project with strict noise regulations, this method was crucial in keeping operations compliant and neighbors happy.

Learn more about advanced damping systems13 that enhance quiet operations—an essential edge in sensitive environments.

By using modern sound-dampening technologies14, continuous drilling maintains a low noise profile while achieving high operational efficiency. These advancements aren't just about meeting regulations—they're about fostering better relationships with communities close to drilling sites.

DTH technology reduces surface noise significantly.True

DTH hammers operate at the hole's bottom, absorbing loud sounds.

Continuous drilling increases noise levels in urban areas.False

Continuous drilling reduces noise through efficient energy transfer.

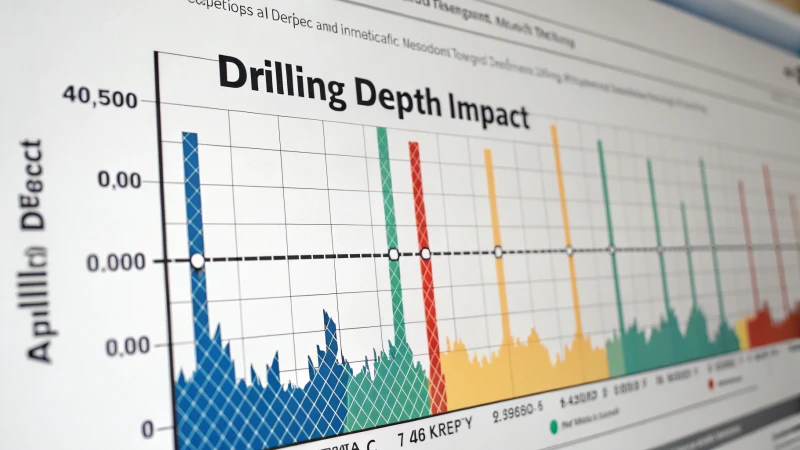

How Does Drilling Depth Affect Acoustic Impact?

Have you ever wondered how the depth of drilling can change the way sound travels and impacts the environment?

Yes, drilling depth can significantly influence acoustic impact by altering noise absorption and vibration transmission. Deeper drilling typically reduces surface noise because the surrounding earth absorbs more sound and vibrations, making operations quieter.

Understanding Acoustic Dynamics in Drilling

I remember my first major drilling project where we were tasked with minimizing noise in a bustling urban area. It was a real challenge, balancing the demands of a tight schedule with the need to keep residents happy. That's when I truly understood how the depth at which we drilled could make all the difference.

In deeper drilling scenarios, the earth acts as a natural sound barrier. This means the deeper the hole, the more efficiently the surrounding material absorbs and dampens both noise and vibrations. It's like nature's own soundproofing system, which I found incredibly fascinating.

Sound Absorption

As drilling progresses deeper, more layers of soil and rock stand between the drill bit and the surface. These layers are critical in absorbing sound waves, reducing noise that reaches above ground. This is especially beneficial in urban settings where noise pollution can be a significant concern. I recall a project near a school where this principle was our saving grace, keeping peace in the neighborhood.

| Depth Range (meters) | Noise Reduction Potential |

|---|---|

| 0-50 | Low |

| 50-100 | Moderate |

| 100+ | High |

Vibration Transmission

The vibration15 aspect of acoustic impact is also influenced by depth. Vibrations from drilling are less likely to travel back to the surface when operations are conducted deep underground. This reduction not only decreases noise but also mitigates potential damage to nearby structures. Once, we worked near a historic site and were able to preserve its integrity thanks to these principles.

Practical Applications

In sensitive areas, especially near residential zones or historical sites, methods like Down-the-Hole (DTH) are preferred due to their quieter operation compared to surface techniques.

Advances in Drilling Technology

Modern advancements have further enhanced our ability to manage acoustic impacts with sophisticated damping systems and innovative16 equipment. Technologies like sound-dampening enclosures and low-noise engines have been game-changers in reducing acoustic emissions.

- Sound-Dampening Enclosures: Surround noisy components to effectively isolate sound emissions.

- Low-Noise Engines: Specially designed to operate with reduced acoustic output.

These elements highlight how crucial drilling depth is in managing acoustic impact, guiding smarter strategic decisions17 in project planning. Each project teaches me something new about balancing technology with nature, ensuring progress without disruption.

Deeper drilling reduces surface noise levels.True

Deeper drilling allows earth layers to absorb sound, reducing noise.

Surface drilling is preferred near residential areas.False

Deep drilling is preferred in sensitive areas due to reduced noise.

Conclusion

DTH drilling is quieter than other methods due to its underground hammer action, which minimizes surface noise and vibrations, making it ideal for urban and sensitive environments.

-

Learn how DTH drilling minimizes noise through underground hammer placement, making it quieter than top hammer methods. ↩

-

Explore innovative technologies that help reduce noise from DTH rigs and enhance compliance with noise regulations. ↩

-

Discover how electric motors offer quieter operation compared to diesel engines, which is crucial for noise-sensitive environments. ↩

-

Explore how DTH drilling offers efficient energy transfer, reducing noise through direct hammer action at the bit. ↩

-

Learn about materials that effectively trap and dissipate sound, enhancing noise reduction in equipment design. ↩

-

Understand different barriers that block sound paths and contribute to lowering external noise levels. ↩

-

Explore how direct energy transfer mechanisms minimize energy loss by reducing intermediary steps, leading to efficient systems. ↩

-

Discover how controlling vibrations leads to less wear and tear, thereby extending the lifespan of machinery and systems. ↩

-

Learn about advanced drilling methods that employ direct energy transfer for efficient operations. ↩

-

Understand how reducing vibrations leads to smoother and more efficient industrial processes. ↩

-

Find out which materials are most effective in dampening vibrations to enhance equipment performance. ↩

-

Discover how DTH drilling reduces surface noise through innovative technology and energy-efficient operations. ↩

-

Explore advanced damping systems used in drilling to manage vibrations and reduce operational noise effectively. ↩

-

Learn about modern sound-dampening technologies that help maintain low noise levels during drilling operations. ↩

-

Explore how vibrations from drilling operations can affect structures and what measures can mitigate these impacts. ↩

-

Discover cutting-edge technologies used to reduce noise during drilling operations. ↩

-

Learn strategies for minimizing noise and vibration impacts in construction projects. ↩