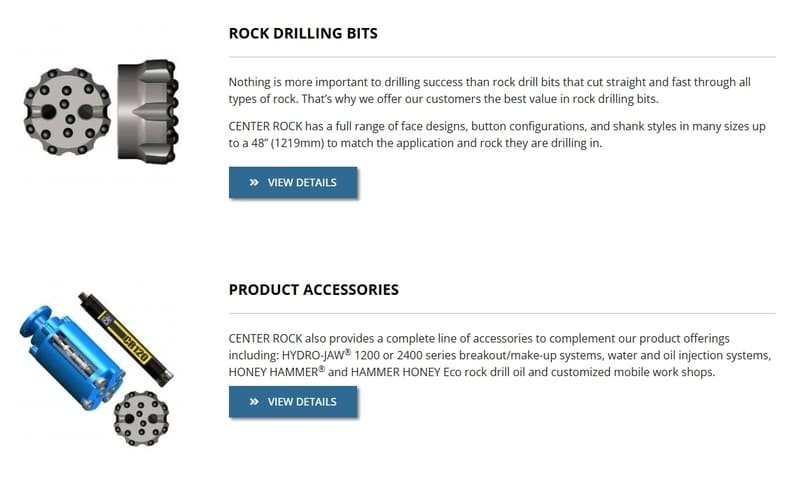

Ever wondered why Center Rock DTH bits are the talk of the drilling world? Let me take you on a journey through their fascinating features.

Center Rock DTH bits stand out for their exceptional durability, innovative designs, and reliable performance in diverse drilling conditions, making them a top choice in industries like mining, construction, and oil and gas.

I remember the first time I encountered a Center Rock DTH bit on a drilling site. The crew was buzzing with excitement, and I soon learned why. These bits are not just tools; they are game-changers. Their ability to power through tough rock formations without faltering is nothing short of impressive. It’s like having a steadfast ally on the field, ensuring that every project runs smoothly and efficiently.

The secret sauce? It’s in the details—superior materials, cutting-edge designs, and a relentless focus on performance. Whether it’s the optimized cutting structures or the superior air flow design, each feature is meticulously crafted to handle the most challenging conditions. And the best part? They offer a wide range of options to fit any project need, making them versatile partners in any drilling endeavor. With Center Rock, you’re not just getting a bit; you’re investing in reliability and innovation.

Center Rock DTH bits are the most durable in the industry.True

Known for their durability, they withstand harsh drilling conditions effectively.

Center Rock DTH bits are only used in the oil and gas industry.False

They are also widely used in mining and construction industries.

Why are Center Rock DTH Bits So Durable?

Ever wondered why some drilling bits seem to last forever? Center Rock DTH bits are the superheroes of the drilling world, with durability that truly impresses.

Center Rock DTH bits achieve exceptional durability through the use of top-grade materials, a robust construction, and advanced design features. These qualities enable them to endure extreme drilling conditions, minimizing equipment downtime and maximizing efficiency.

High-Quality Materials

One of the key factors contributing to the durability of Center Rock DTH bits is the use of high-quality materials. I remember standing at a drilling site, marveling at how these bits could take such a beating. It's all in the materials they use. Center Rock DTH bits are crafted from top-grade steel and premium carbide. These aren't just buzzwords—they're the backbone of what makes these bits withstand the punishing demands of drilling.

| Material | Benefit |

|---|---|

| Steel | Provides structural integrity and resistance to wear |

| Carbide | Enhances cutting efficiency and wear resistance |

These materials ensure both strength and longevity, making them indispensable in harsh environments.

Robust Construction

Once, during a particularly challenging project, I realized just how vital robust construction is. Imagine being in the middle of nowhere, relying on your equipment to pull through. The construction of these bits is designed to survive demanding conditions, whether you're in mining, construction, or oil and gas exploration. This reliability keeps operations running smoothly without constant interruptions for equipment failures.

Advanced Design Features

Center Rock DTH bits feature optimized cutting structures with advanced geometries and customized carbide button layouts tailored for various rock formations. It's like they've thought of everything—these designs boost penetration rates and improve rock fragmentation efficiency.

Superior Air Flow Design

Moreover, their superior air flow design enhances debris removal and cooling during operations, which prevents bit overheating and prolongs tool life1. Those engineered air channels make sure debris is cleared quickly and efficiently, keeping the bits cool and functional.

For more insights on these amazing features, dive into the technical specifications2 of Center Rock DTH bits.

Versatility and Customization

Center Rock offers a range of sizes and designs to fit various drilling needs. I once worked on a project where standard bits just wouldn't cut it—literally—and customization was the hero of the day. Clients can select from a wide variety of options or opt for customized bits tailored to specific drilling conditions. This adaptability ensures you can tackle any project, whether it's in soft or hard rock formations.

Center Rock DTH bits use top-grade steel and carbide.True

The materials provide structural integrity and wear resistance.

Center Rock DTH bits lack customization options.False

They offer a variety of sizes and designs for diverse needs.

How Does Center Rock Ensure Superior Performance in Diverse Conditions?

I remember the first time I encountered a Center Rock product on-site; it was a revelation in efficiency and durability. What makes these tools excel, especially in tough conditions?

Center Rock ensures superior performance in diverse conditions by using durable materials, cutting-edge design features, and innovative technology. Their tools, such as DTH bits, are specifically engineered to endure harsh environments, delivering consistent reliability and efficiency.

Exceptional Durability and Toughness

I once visited a site where the drilling conditions were particularly harsh—unforgiving rock layers and abrasive materials that could wear out lesser tools in no time. Center Rock's products, however, stood out with their exceptional durability. Made from high-quality materials like top-grade steel and premium carbide, these tools are designed to withstand the toughest conditions without missing a beat.

Material Benefits:

| Material | Benefits |

|---|---|

| Top-grade Steel | Enhances strength and resistance to wear |

| Premium Carbide | Offers superior hardness for cutting efficiency |

Advanced Design Features

During one of my projects, I noticed how the advanced design features of Center Rock’s tools made a significant difference. With optimized cutting structures and superior air flow design, they handle different geological formations effortlessly. This thoughtful engineering maximizes penetration rates and enhances rock fragmentation efficiency—something I've seen firsthand as it sped up our project timeline remarkably.

- Optimized Cutting Structures: Crucial for maximizing penetration rates in varied rock formations.

- Superior Air Flow Design: Efficient air flow keeps tools cool and efficient, preventing overheating during operations.

Wide Range of Bit Options

Center Rock's versatility is another aspect that can't be overstated. They offer a wide range of bit sizes and designs3, which means you can always find the right tool for the job, whether you're dealing with soft or hard rock formations. I’ve often customized bits for unique projects, ensuring we had exactly what was needed for optimal performance.

- Customization Options: Essential for specialized projects where standard bits may fall short.

Innovative Technology

Innovation is at the heart of Center Rock's product development. Their commitment to continuous research and development results in cutting-edge solutions that enhance operational efficiency. Products like their CR line of DTH hammers4 exemplify this innovation—tools designed for the most challenging environments.

- Unique Solutions: Reflecting the company’s dedication to innovation, these products boost operational efficiency.

By focusing on these core areas, Center Rock ensures their tools deliver reliable performance across a multitude of challenging conditions. This commitment to quality and innovation is why I trust their products on demanding projects time and again.

Center Rock uses top-grade steel in their products.True

Top-grade steel enhances strength and resistance to wear in tools.

Center Rock's DTH bits are not customizable.False

Center Rock offers customization to meet diverse drilling needs.

What Makes Center Rock DTH Bits Exceptional?

Ever wondered what makes Center Rock DTH bits the go-to choice for tough drilling jobs? Let's dive into the design features that make them stand out.

Center Rock's DTH bits feature optimized cutting structures and advanced air flow designs, significantly boosting penetration rates and debris removal. These innovations ensure the bits' durability and efficiency across a wide range of challenging drilling environments.

My Journey with Center Rock DTH Bits

I remember the first time I encountered Center Rock DTH bits on a project. It was like meeting a celebrity in the world of drilling! Their reputation for tackling the toughest conditions had preceded them. My curiosity piqued, I had to dig deeper—pun intended—into what made these bits so special.

Optimized Cutting Structures

The cutting-edge geometries and carbide button layouts of Center Rock's bits are like having a tailor-made suit for your drilling needs. Imagine going to a tailor who knows exactly how to craft an outfit that fits you perfectly, enhancing every movement you make. That's what these bits do—they're crafted to match specific rock formations, maximizing penetration rates and rock fragmentation. When I first saw how efficiently they sliced through tough rock, it felt like watching a master chef cut through a steak with a perfectly honed knife.

Enhanced Penetration Rates

These cutting structures are precision-engineered for increased penetration rates, adapting to both soft and hard rock formations. I remember working on a project where switching to these bits felt like upgrading from a bicycle to a sports car. The performance improvement was undeniable, allowing us to achieve optimal drilling efficiency5 with minimal wear.

Superior Air Flow Design

Air flow might not sound glamorous, but trust me, it's vital. Center Rock's bits are designed to maximize air flow, which is crucial for preventing overheating and maintaining cutting efficiency. Think of it like having a top-notch cooling system in your car engine—keeping things running smoothly and extending the lifespan of your equipment. Efficient air circulation also means less downtime, which every operator appreciates.

Table: Air Flow Benefits

| Feature | Benefit |

|---|---|

| Maximized Air Flow | Prevents overheating |

| Efficient Debris Removal | Maintains cutting efficiency |

| Enhanced Durability | Extends bit lifespan |

Customization and Versatility

One of the things I love about Center Rock is their commitment to customization. They offer a broad range of bit sizes and designs, catering to different drilling conditions. Whether you're facing soft rock6 or tackling complex geological settings, there's a tailored solution waiting for you. It's like having a toolbox where every tool fits perfectly for the job at hand.

Tailored Solutions

Clients can request customizations to meet specific drilling requirements. This flexibility is particularly beneficial when standard solutions just won't cut it—literally. I've seen firsthand how these tailored solutions transform challenging projects into manageable tasks, particularly in specialized industries like mining or oil & gas exploration.

Continuous Innovation

Center Rock's commitment to innovation keeps them at the forefront of the industry. Their ongoing research and development mean they're always refining their products, incorporating cutting-edge technologies that enhance drilling performance and operational efficiency. Investing in advanced technologies7 ensures that Center Rock's solutions remain reliable and effective, no matter the evolving demands of the drilling industry.

In my experience, when you invest in quality tools like these, you not only improve your project outcomes but also gain peace of mind knowing you're equipped with the best in the business.

Center Rock DTH bits enhance penetration rates in all rock types.True

The optimized cutting structures improve performance in both soft and hard rock.

Superior air flow design in DTH bits prevents overheating.True

Efficient air circulation helps maintain cutting efficiency and bit longevity.

How versatile are Center Rock DTH bits for different drilling needs?

When I first encountered Center Rock DTH bits, I was curious about their true versatility. Could they really handle the diverse drilling challenges we face daily?

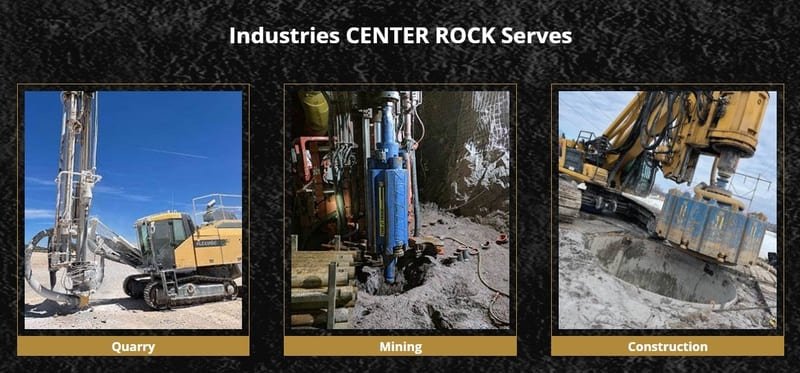

Center Rock DTH bits excel in versatility thanks to their robust construction, innovative design, and wide range of options. These qualities enable them to meet diverse drilling needs efficiently, from mining to construction.

Robust Construction for Varied Environments

In the world of drilling, durability is king. I remember the first time our team faced an unexpected rocky challenge on site. With Center Rock DTH bits, crafted from high-quality steel and premium carbide, we powered through without a hitch. These bits are like the workhorses of the drilling world, enduring tough conditions with minimal downtime and fewer replacements.

Advanced Design Features

Imagine cutting through rock like slicing through butter—that’s what these bits can feel like. The advanced geometries and carbide button layouts make penetration faster and rock fragmentation more efficient. I’ve noticed how the superior airflow design helps keep things cool, reducing overheating and extending the bit's life, which is a huge relief during intense projects.

Key Specifications:

| Feature | Description |

|---|---|

| Material Quality | Top-grade steel and carbide for durability |

| Cutting Structures | Advanced geometries for optimized penetration |

| Air Flow Design | Enhanced debris removal and cooling capabilities |

Wide Range of Options

One of the best things about Center Rock is their range of options. Whether it's soft or hard rock, they’ve got a bit for every scenario. I remember customizing a set for a particularly challenging job, which made all the difference. It’s comforting to know there’s flexibility to match specific project needs.

Continuous Innovation and Proven Track Record

Center Rock’s commitment to innovation reminds me of why I keep returning to them. They are constantly refining their products through R&D, ensuring they remain cutting-edge. The positive feedback from other industry professionals and the success stories from high-profile projects we’ve been a part of speak volumes about their reliability.

Practical Applications

Across various industries—from mining operations8 to oil and gas—these bits have proven their mettle. Their ability to maintain performance in different environmental conditions is a testament to their adaptability, making them invaluable in meeting diverse project demands.

Center Rock DTH bits are made from premium materials.True

The bits are crafted from high-quality steel and carbide for durability.

Center Rock DTH bits lack customization options.False

They offer a broad selection and customization to suit drilling needs.

What Innovations Set Center Rock DTH Bits Apart from Competitors?

Ever felt like you’re on a never-ending quest for the perfect drill bit? Discover how Center Rock's DTH bits might just be the game-changer you’ve been searching for.

Center Rock DTH bits are uniquely designed for exceptional durability, optimized cutting structures, and enhanced air flow, ensuring superior performance in varied drilling conditions compared to their competitors.

Exceptional Durability and Toughness

Imagine being out on a job, tackling some tough rock formations, and not having to worry about your equipment letting you down. Center Rock DTH bits, crafted from high-quality steel and premium carbide, offer that peace of mind. Their construction is rugged enough to handle extreme conditions, making frequent replacements a thing of the past. This durability is especially crucial in fields like mining and construction9, where downtime can mean serious setbacks.

Advanced Design Features

Optimized Cutting Structures

Have you ever noticed how some drills just seem to get the job done faster? That’s the magic of an optimized cutting structure. Center Rock’s DTH bits use advanced geometries and strategically placed carbide button layouts to power through rock formations efficiently. It’s like having a secret weapon for rock fragmentation that ensures you hit those operational targets with ease.

Superior Air Flow Design

Keeping things cool under pressure isn’t just for us humans; it’s crucial for drill bits too. Center Rock's superior air flow design ensures effective debris removal and cooling during drilling. This feature not only prevents overheating but also extends the life of the bit, giving it a competitive edge.

| Feature | Benefit |

|---|---|

| Optimized Cutting Structure | Maximized penetration rates |

| Superior Air Flow Design | Enhanced cooling & longevity |

Wide Range of Bit Options

One size doesn’t fit all when it comes to drilling projects. Whether you're dealing with soft rock or complex formations, Center Rock offers a variety of DTH bit sizes and designs to meet diverse needs. This versatility ensures that whatever the challenge, there’s a solution tailored just for it.

Innovative Technology

Center Rock's dedication to innovation means they’re always pushing the envelope. Their CR line of DTH hammers showcases this commitment, engineered for peak performance in even the toughest environments. Curious about how these innovations enhance operational efficiency? Dive into the details of their CR line of hammers10 to see how they can transform your projects.

Center Rock DTH bits use premium carbide for durability.True

Premium carbide enhances durability, reducing replacements in tough conditions.

Center Rock DTH bits lack advanced airflow design features.False

They have superior airflow design for cooling and debris removal efficiency.

How does Center Rock's quality control boost bit reliability?

Ever wonder how some drill bits manage to keep going, even in the toughest conditions? Center Rock's got a secret weapon: top-notch quality control. Let's dive into how they make those bits last longer and work harder.

Center Rock ensures bit reliability through rigorous quality control measures like ultrasonic testing and defect screening. These steps guarantee durability and reduce operational downtime.

Importance of Quality Control in Drilling

Quality control in the drilling world isn't just about ticking boxes—it's about survival. I remember the first time I realized just how crucial it was. Picture this: I'm on-site, knee-deep in paperwork, when a drill bit fails unexpectedly. The chaos that ensued was a wake-up call, underscoring the need for tools that can withstand the harshest environments. For Center Rock, this means rigorous testing methods11 to ensure their products are battle-ready.

Ultrasonic Testing of Forgings

One standout in Center Rock's arsenal is ultrasonic testing. Imagine a sonar for metal—a fascinating process where high-frequency sound waves uncover hidden flaws. I once saw this test catch an imperfection that could've turned a simple job into a major setback. By nipping these issues in the bud, Center Rock keeps their bits up to par in terms of structural integrity12.

Benefits of Ultrasonic Testing

- Early Detection: Catching flaws before they become disasters.

- Non-Destructive: Testing without a scratch on the product.

- Precision: Offering a peek inside, revealing the bit’s true structure.

| Feature | Description |

|---|---|

| Early Flaw Detection | Identifies potential issues before use |

| Non-Destructive | Tests without damaging the product |

| High Precision | Delivers detailed internal structural information |

Screening for Inclusions and Flaws

This one's close to my heart—screening for inclusions. These sneaky particles can spell disaster if left unchecked. I've seen firsthand how meticulous screening at Center Rock leads to bits that don't just perform well; they go the distance.

How Screening Improves Reliability

- Consistency: Making sure every bit behaves predictably.

- Durability: Helping the bits withstand the test of time.

- Safety: Preventing those nail-biting moments in critical applications.

Ensuring Consistent Performance

All these quality control measures come together to create a product that's not just durable, but reliably so. This consistency is what makes operations smooth, minimizing any downtime in operations13. Each bit undergoes rigorous testing before it lands in your toolbox, ready to deliver top-notch performance across various scenarios.

Key Takeaways

- Center Rock’s quality control features advanced techniques like ultrasonic testing.

- Screening for defects bolsters bit longevity and reliability.

- Consistent quality management helps cut down on operational hiccups.

These practices highlight why investing in reliable equipment is essential—not just for getting the job done, but for ensuring safety and success in every drilling project. So next time you're out there facing the elements, know that with Center Rock, your tools are right there with you, ready for whatever comes next.

Ultrasonic testing is destructive to drill bits.False

Ultrasonic testing is non-destructive, preserving the bit's integrity.

Inclusions can weaken drill bits and cause failures.True

Non-metallic inclusions in metal can lead to premature failure.

Conclusion

Center Rock DTH bits are renowned for their durability, innovative designs, and reliable performance across various drilling conditions, making them a preferred choice in mining, construction, and oil industries.

-

Discover the importance of efficient air flow in enhancing drill bit performance and longevity. ↩

-

Explore detailed technical specifications that highlight the performance features of Center Rock DTH bits. ↩

-

Explore the extensive range of DTH bit designs offered by Center Rock for various drilling needs. ↩

-

Premium carbide enhances drill bit durability and efficiency in cutting through tough materials. ↩

-

Discover how Center Rock's design enhances drilling efficiency across various rock formations. ↩

-

Explore how Center Rock DTH bits adapt to soft rock formations for optimal performance. ↩

-

Find out about the latest technological innovations in Center Rock's DTH bits. ↩

-

Learn about the successful applications of Center Rock DTH bits in mining operations globally. ↩

-

Understanding material benefits helps evaluate durability, crucial for demanding industries like mining and construction. ↩

-

Learning about the CR line reveals innovative features that enhance drilling efficiency in tough environments. ↩

-

Ultrasonic testing is essential in detecting internal defects, improving product reliability and safety. ↩

-

Ultrasonic testing offers precise flaw detection without damaging the product, making it superior to other methods. ↩

-

Consistent performance ensures reduced downtime, enhancing operational efficiency and reliability in industrial settings. ↩