Picture yourself in the center of a dusty drilling site, wondering when to sharpen the button bits for top performance.

The ideal moment to sharpen a button bit arrives when the wear flat ratio reaches 40-50%. Another good time is if button protrusion falls below half its diameter. Monitor gauge button wear and check how deep it drills. Regular checks help spot signs of heat-induced cracks.

I remember my first day at a drilling site. The machinery and noise frightened me. The work was hard. Grinding the button bits at the right time confused me. I later understood that watching these signals stopped expensive delays. The drilling work became really efficient. Learning these details changed everything. Work saved both time and resources. These signals matter a lot. Let's explore how these signals can very much improve your work.

Grinding a button bit at 30% wear flat ratio is optimal.False

Optimal grinding is at 40-50% wear flat ratio, not 30%.

Button protrusion should be half the diameter before grinding.True

Grinding is recommended when button protrusion drops below half the diameter.

How Does Wear Flat Ratio Affect Button Bit Performance?

Think of drilling into rock with a blunt tool; this occurs when people ignore the wear flat ratio.

The wear flat ratio affects how well the button bit works. It shows the right time to grind the bit. A high ratio leads to slower drilling and uses more energy. This reduces efficiency. This also risks breaking the bit.

Understanding Wear Flat Ratio

I remember when I first heard about the wear flat ratio. It felt like solving a puzzle. This ratio measures the width of the worn area compared to the button's diameter. It shows the bit's condition clearly. Observing these numbers changed how smoothly our work proceeded.

| Wear Flat Ratio | Condition | Action Required |

|---|---|---|

| 0-30% | Good | Monitor |

| 30-50% | Moderate | Consider Grinding |

| 50%+ | Critical | Immediate Grinding |

Checking this ratio is like checking your car's oil. Ignoring it leads to more problems. A ratio over 50% warns you. Efficiency will go down and costs will rise.

Impact on Drilling Efficiency

During a tough project, I saw how much the wear flat ratio affects drilling speed. As this number goes up, the drill bit needs extra power to continue. This slows everything and increases costs. Watching the button's protrusion - maintaining a minimum of half the button's diameter - helps keep everything optimal.

Button protrusion1 becomes critical in ensuring optimal performance.

Energy Consumption and Cost Implications

High wear flat ratios lead to more than just slowdowns - they really cost money in extra fuel and possible delays. It's like trying to run a marathon in really bad shoes. Regular checks help spot these problems early.

Higher wear flat ratios mean that more force is needed to achieve desired penetration rates, resulting in higher fuel consumption and operational costs.

Maintenance and Longevity

Proactive care makes button bits last longer. By following a grinding schedule based on wear flat ratios, I have seen better drilling results and fewer expensive replacements. Staying ahead is crucial to avoid big issues.

Regular inspections and timely grinding based on the wear flat ratio can significantly extend the life of button bits, enhancing drilling productivity2 while minimizing costs associated with frequent replacements.

Mastering the wear flat ratio is about efficient and cost-effective operations. This ratio is critical; it keeps our processes smooth and equipment lasting for a long time.

A wear flat ratio over 50% indicates critical wear.True

A ratio above 50% suggests significant wear, needing immediate grinding.

Higher wear flat ratios increase drilling efficiency.False

Increased ratios decrease penetration rates, reducing drilling efficiency.

Why is button protrusion crucial for drilling efficiency?

Did you ever think how a small change in design might transform your drilling work?

Button protrusion helps drilling work by keeping the drill bit in good contact with the rock. Good button protrusion increases penetration rates. It also reduces wear. It extends the life of drilling tools.

Understanding Button Protrusion

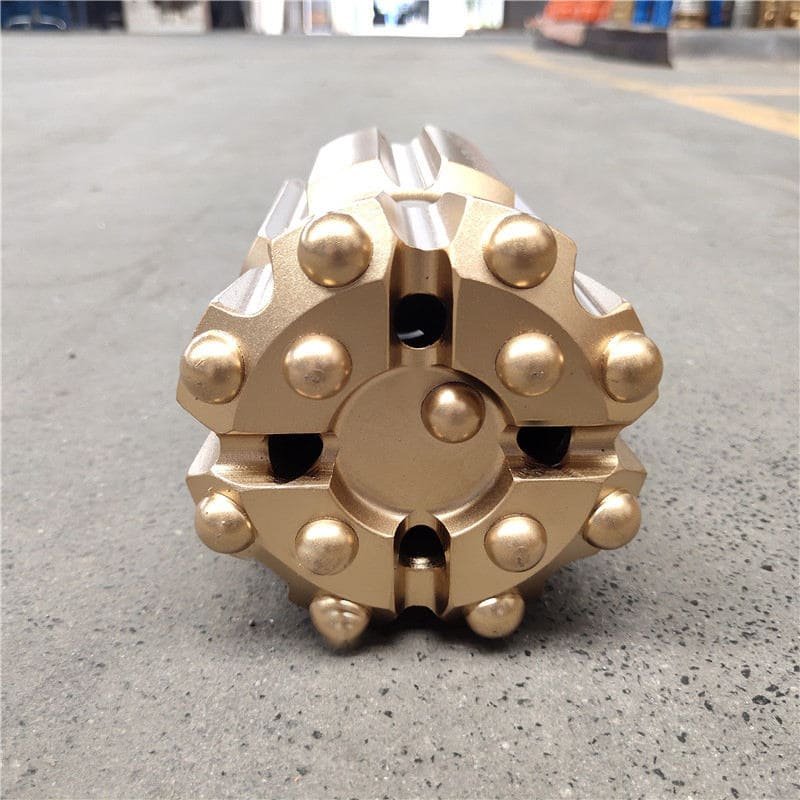

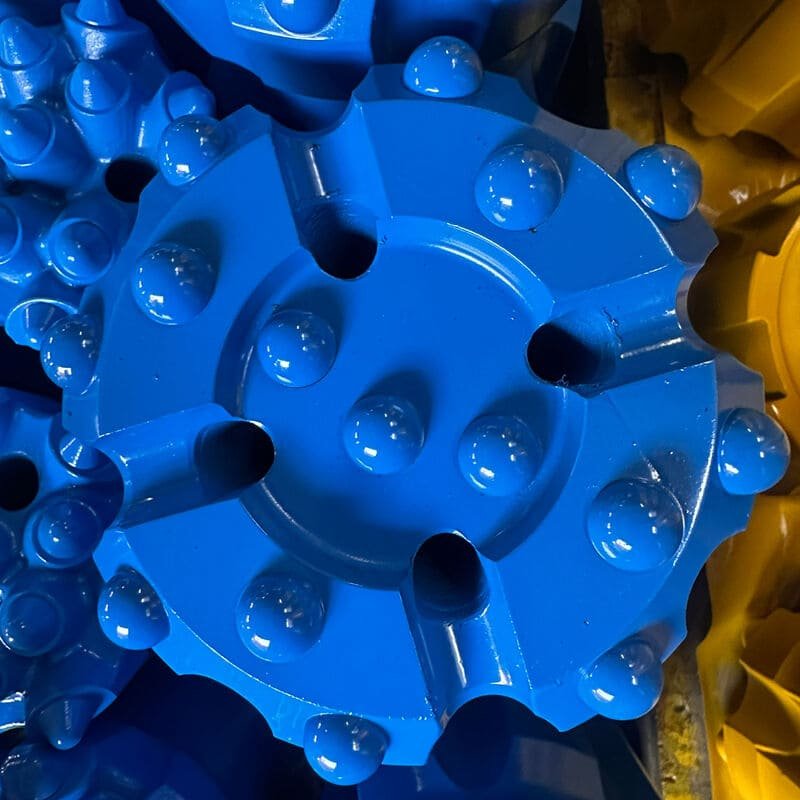

Button protrusion always fascinates me. Such a small detail greatly affects drilling performance. It shows how far the tungsten carbide buttons stick out from the drill bit's surface. This may seem unimportant, but it controls the first contact point with the rock.

When I learned about button protrusion3, its impact surprised me. Keeping it within the right range lets drill bits send energy well from the hammer to the rock. This speeds up drilling and cuts down on drilling time. Very important.

Impact on Penetration Rate

I worked on a project where we changed button protrusion. The result amazed us - a huge rise in penetration rates. The protruding buttons broke rocks more efficiently, making drilling faster.

I saw the opposite too. If button protrusion is too low, the drill bit struggles. Poor contact with the rock makes drilling less effective.

| Button Protrusion | Impact on Efficiency |

|---|---|

| High | Higher penetration rates |

| Low | Reduced efficiency |

Effects on Wear and Tool Life

Wear mostly happens at the buttons. Keeping correct button protrusion spreads wear evenly, easing stress on the bit. Watching wear patterns and grinding when needed keeps the buttons in shape and extends the bit's life.

Grinding techniques4 are very important. They need special machines for removing material accurately without harming the buttons.

Considerations for Different Rock Types

I found that button protrusion levels change based on rock type and hardness. Softer rocks need less protrusion. Harder rocks need more to drill effectively.

Knowing this helps operators like me adjust equipment or choose different bits. These adjustments boost efficiency across varied geological conditions. Adjusting button protrusion also changes impact force distribution and energy use, which are crucial for drilling success5.

Higher button protrusion increases penetration rates.True

Protruded buttons create efficient fracture mechanisms, enhancing drilling speed.

Low button protrusion prolongs drill bit lifespan.False

Low protrusion reduces efficiency and unevenly distributes wear, shortening lifespan.

Why Are Gauge Buttons Important in Maintenance Decisions?

Have you ever thought about how a tiny gauge button might really change your equipment's performance?

Gauge buttons hold great importance in maintenance choices. They help track the wear and deterioration of drilling tools. Excellent condition of these buttons stops early breakdown. It also increases output. Equipment lasts longer with good care.

Understanding Gauge Buttons

I remember my first day at work, looking at the small gauge buttons and wondering why they mattered so much. Soon, I discovered these tiny parts are vital. Gauge buttons in drilling bits keep the drill hole the right size by keeping the bit in shape during use. This is very important as it directly impacts penetration rates6 and the quality of our projects.

Maintenance Clues

-

Wear Flat Ratio

Avoiding surprise breakdowns means watching indicators like the wear flat ratio closely. When this hits between 0.25 to 0.33 times the button size, you should consider grinding7. Believe me, checking these numbers can really save you trouble.

| Indicator | Threshold |

|---|---|

| Wear Flat Ratio | 0.25-0.33 |

| Button Protrusion | <50% diameter |

| Penetration Rate | Decline |

Factors for Maintenance Choices

- Operational Environment: Over the years, I noticed rough working conditions speed up wear and tear, so regular checks are necessary to adjust maintenance schedules accordingly.

- Visual Inspections: A quick look can show problems like heat cracks or "snake skin" on the buttons - clear signs that fast action is required.

Real-Life Examples

In some projects with rough materials, gauge buttons wore out faster than we thought. Frequent inspections8 became crucial for us, letting us step in quickly and extend the life of our bits.

Importance of Regular Maintenance

I know from experience that keeping gauge buttons well-maintained stops early failures and keeps drilling steady. It's a habit that cuts costs and improves equipment efficiency9. Following a strict maintenance routine has saved us lots of money over time—a little care really matters.

Gauge buttons maintain drill bit shape.True

Gauge buttons help retain the drill bit's diameter, ensuring efficiency.

Wear flat ratio above 0.33 is optimal.False

A wear flat ratio of 0.25-0.33 indicates maintenance is needed.

How Can Penetration Rate Indicate It's Time for Grinding?

Ever worked on a project and felt like your drill wasn't quite effective? Choosing the correct time to sharpen those drill bits is very important.

The speed of a drill shows when you need to grind. A drop in speed clearly signals that the button bits are becoming dull. Grinding is needed to keep work smooth and very efficient. It is important to act when you notice this change.

Understanding Penetration Rate

I remember when I first understood the importance of watching the penetration rate closely. It was during a tough drilling job where every second was crucial. The penetration rate shows how fast a drill bit moves through materials like rock. Many things affect it, including how hard the material is, the condition of the bit, and the drilling technique used. By watching these, I learned when bits were not working well and needed sharpening.

The Relationship Between Penetration Rate and Bit Condition

A stable penetration rate often means the bit is in good shape. But if it slows down, the cutting parts are likely too dull. This means it's time to sharpen. Here's a simple table I use:

| Condition | Action Required |

|---|---|

| Stable Penetration Rate | Continue Monitoring |

| Decreasing Rate | Schedule Sharpening |

| Significant Drop | Immediate Sharpening Needed |

Factors Affecting Penetration Rate

Several things influence how quickly a drill bit cuts through:

- Material Hardness: Harder materials slow it down.

- Bit Design: The design greatly affects cutting ability.

- Operational Techniques: Speed and pressure matter.

- Bit Wear: More wear means less penetration, signaling for maintenance10.

Monitoring Techniques

To know when sharpening is needed, I rely on these techniques:

- Regular Inspections: I look for patterns like "snake skin" on bits.

- Data Tracking: Drilling logs help me see rate changes.

- Technological Tools: Sensors and software notify me about performance dips.

By using these methods, I have really increased operational efficiency. Equipment lasts longer, saving costs from worn-out bits. This careful plan keeps everything smooth and improves performance outcomes11.

A stable penetration rate means no grinding needed.True

A consistent rate indicates the bit is well-maintained and effective.

Harder materials increase penetration rates.False

Harder materials slow down penetration, requiring more effort to drill.

How Can You Tell It's Time to Grind a Button Bit?

You find yourself drilling and suddenly the bit stops working properly. Realizing it's time to sharpen the bit avoids future problems.

When wear flat ratios reach 40-50%, button protrusion drops. You might see snake skin patterns or thermal cracks. This signals a need to grind your button bit. This helps everything function well.

Understanding Wear Flat Ratio

Let's discuss the wear flat ratio, a term that sounds complex but is quite simple. Imagine you look at your bit and see the worn area is nearly half the size of the button. This is a sign. Once it reaches 40-50%, grinding is needed. This small action changes everything by keeping drilling effective and extending bit life. It's important. Very important.

| Wear Flat Ratio | Action Required |

|---|---|

| < 40% | Continue Monitoring |

| 40-50% | Time to Grind |

| > 50% | Immediate Grinding |

Monitoring Button Protrusion

Button protrusion may not cross your mind often, but its role is crucial. If this protrusion falls below half the diameter, grinding is necessary. Watching this can prevent larger problems. Routine checks12 stop unwanted wear and keep everything smooth.

Gauge Buttons: Key Indicators

Gauge buttons are vital yet often overlooked - they bear the brunt on the edge. When wear flat reaches 0.25-0.33 times the button diameter, grinding is needed. Keeping these in good condition keeps your drilling precise.

Visual Clues: Snake Skin and Cracks

Seeing "snake skin" patterns or cracks is like an alert from your bit. These are signs of stress or overheating, demanding quick grinding. Ignoring them could cause serious failures. Quick checks can prevent much trouble.

Visual inspection13 helps identify these issues early on.

Assessing Penetration Rate

Penetration rate acts as a gauge for your drilling performance. If it declines, probably wear is present and grinding might help. Being alert keeps productivity high and reduces downtime.

Integrating these checks into regular upkeep prolongs button bit life and maintains efficient operations. Recognizing these signals and reacting promptly keeps everything working well.

A wear flat ratio over 50% requires immediate grinding.True

A wear flat ratio exceeding 50% indicates severe wear, needing urgent grinding.

Button protrusion below half diameter is acceptable.False

Button protrusion should be at least half the diameter to ensure efficiency.

Conclusion

Sharpen button bits when wear flat ratios reach 40-50% or button protrusion drops below half diameter. Regular checks enhance drilling efficiency and prolong tool life.

-

This link explains button protrusion's role in maintaining optimal drilling performance. ↩

-

Explore strategies to enhance drilling productivity through effective maintenance practices. ↩

-

Explore how button protrusion affects contact and energy transfer efficiency during drilling. ↩

-

Learn about various grinding techniques that maintain button integrity and extend tool life. ↩

-

Discover strategies to enhance drilling performance through optimal equipment settings. ↩

-

Understanding penetration rates helps evaluate drilling efficiency, which is crucial for maintaining optimal operations. ↩

-

Learning effective grinding techniques ensures longevity and performance of gauge buttons. ↩

-

Identifying thermal cracks early can prevent significant damage and costly repairs. ↩

-

Regular maintenance ensures operational efficiency and reduces unexpected downtime. ↩

-

Understanding wear impact helps identify when maintenance is crucial to avoid inefficiencies. ↩

-

Explore effective methods to enhance drilling performance and equipment longevity. ↩

-

Monitoring button protrusion helps maintain drilling efficiency by alerting you when grinding is necessary. ↩

-

Understanding thermal damage effects can prevent unexpected bit failures and extend tool life. ↩