Picking the right steel for drill bits can make or break your project, literally!

Choosing the best steel for drill bit bodies hinges on your drilling needs. High-carbon steel, Chromoly, and tool steels are go-to options because of their durability and resistance to wear.

Imagine you're halfway through a DIY project and your drill bit snaps—frustrating, right? I’ve been there, and trust me, selecting the right steel can prevent those setbacks. Let’s dive into how different steels handle various conditions and figure out which might be your project's hero.

High-carbon steel is ideal for all drill bit applications.False

High-carbon steel is strong but not suitable for high-temperature drilling.

Tungsten carbide is used for wear-resistant parts of drill bits.True

Tungsten carbide is often used for cutting parts due to its hardness.

Why is High-Carbon Steel Popular for Drill Bits?

There's something almost magical about high-carbon steel when it comes to drill bits.

High-carbon steel drill bits are loved for their exceptional hardness and wear resistance, making them perfect for tough drilling tasks. Their ability to endure stress and stay sharp in demanding conditions is why they're a favorite in the industry.

The Composition and Properties of High-Carbon Steel

High-carbon steel typically contains carbon content ranging from 0.6% to 1.5%. This elevated carbon content enhances the steel's hardness and wear resistance, crucial for drill bits that face rigorous conditions. Unlike lower carbon steels, high-carbon variants can be heat-treated to further improve these properties, making them highly effective in demanding drilling environments1.

Advantages in Drilling Applications

The robustness of high-carbon steel makes it suitable for both industrial and DIY projects. It efficiently drills through metals, woods, and some softer stones. Its ability to retain a sharp edge means less frequent replacements and maintenance. This characteristic is especially valued in industries where downtime equates to significant losses, as seen in construction and manufacturing sectors2.

Heat Treatment Enhancements

One of the significant benefits of high-carbon steel is its adaptability through heat treatment processes like hardening and tempering. These processes enhance its toughness while maintaining hardness. For instance, during the tempering process, the steel is heated to a precise temperature and then cooled, reducing brittleness and increasing ductility. Such treatments are critical for extending drill bit lifespan3 and performance in challenging environments.

Cost-Effectiveness and Availability

High-carbon steel offers a balance between performance and cost-effectiveness. Its widespread availability and relatively lower cost compared to other specialized materials like tungsten carbide make it a go-to choice for many manufacturers. The cost benefits extend to consumers who require reliable tools without breaking the bank, which can be seen in everyday hardware tools4.

High-carbon steel is ideal for high-temperature drilling.False

Chromoly, not high-carbon steel, excels in high-temperature conditions.

Tool steels are alloyed with tungsten for hardness.True

Tungsten enhances hardness, crucial for tool steels' performance.

How Does Chromium-Molybdenum Steel Enhance Drill Bit Performance?

I remember my first drilling project where the drill bits kept failing. Discovering chromoly steel changed everything.

Chromium-molybdenum steel, with its exceptional strength, impact resistance, and thermal stability, boosts drill bit performance by enhancing durability and efficiency in tough drilling conditions.

The Composition of Chromium-Molybdenum Steel

I once found myself knee-deep in a challenging drilling project, desperately needing a solution for the constant breakage of drill bits. That's when I learned about chromium-molybdenum steel—an alloy that combines the best of chromium and molybdenum. This blend results in a material that's both tough and heat-resistant. Chromium adds corrosion resistance5 and hardenability, while molybdenum provides strength at high temperatures.

Benefits in High-Stress Drilling

My experience has taught me that chromoly steel drill bits are lifesavers in high-stress environments. Whether it's deep drilling where temperatures skyrocket or just dealing with tough materials, these bits maintain their integrity thanks to the molybdenum. The result? Longer operational life and fewer replacements6, which is always a win in my book.

Impact Resistance and Fatigue Strength

One standout memory is watching a chromoly bit withstand relentless hammering in a percussive drilling application. Its impressive impact resistance prevented structural failures7 time and again, extending the bit's lifespan significantly.

Heat Treatment Processes

Another game-changer for me was learning about heat treatment processes like tempering and annealing. These techniques optimize the performance of chromoly steel drill bits by enhancing their mechanical properties, ensuring they remain hard and tough under various conditions.

Comparison with Other Alloy Steels

I've often compared chromoly to other steels like high-speed or nickel-chromium-molybdenum. What stands out is its balance of toughness and wear resistance, often providing a more cost-effective solution without compromising on performance8. It's the kind of reliability that keeps projects on track and budgets in check.

Chromoly steel enhances drill bit toughness.True

Chromium and molybdenum in chromoly steel improve toughness and impact resistance.

Tool steel is unsuitable for high-temperature drilling.False

Tool steels maintain high hardness at elevated temperatures, ideal for such conditions.

Why is Tool Steel the Best Choice for Durability?

Ever wondered why tool steel is the durability champion? Let me share its secrets with you.

Tool steel is highly durable due to its remarkable hardness, superior wear resistance, and ability to maintain strength at high temperatures. These qualities make it a top choice for tools and machinery that operate in challenging environments.

Composition and Properties of Tool Steel

When I first started exploring materials for my projects, I quickly learned about the wonders of tool steel. It’s a type of carbon and alloy steel that boasts impressive hardness and heat resistance. This magic happens thanks to elements like tungsten, molybdenum, cobalt, and vanadium. Imagine needing a tool that can cut through metal like butter—tool steel can do just that. These elements combine to enhance its wear resistance and toughness, which are crucial for applications like cutting and shaping other metals. The unique blend of alloying elements9 allows tool steel to keep a sharp edge even after countless uses.

Heat Treatment and Hardness

I remember the first time I witnessed the heat treatment process—it was like watching a blacksmith conjure magic. This process is where tool steel truly shines. By hardening and tempering, the steel achieves extraordinary hardness without losing its toughness. Imagine working with tools in high-stress environments; you need them to be reliable and resilient. Heat treatment ensures that tool steel meets these demands, offering customizable properties tailored to specific industrial needs so that they can brave intense conditions10.

Applications in Various Industries

Tool steel is the unsung hero in many industries, often saving the day with its precision and durability. Whether it's in the automotive industry, ensuring engine components withstand high temperatures and stress, or in construction, where heavy machinery demands resilience, tool steel is there. I’ve seen firsthand how it’s used in hand tools, cutting implements, and molds—always delivering on precision and longevity. These diverse applications11 underscore why manufacturers keep it as their go-to material.

Comparison with Other Steels

In my journey to understand materials better, I've often compared tool steel to others like high-carbon or stainless steel. While high-carbon steel offers decent hardness, it doesn’t hold up to the wear resistance and toughness of tool steel. And even though stainless steel is great against corrosion, it lacks the necessary hardness for heavy-duty tools. Tool steel strikes the perfect balance of strength and resilience12, proving its mettle in demanding applications.

High-carbon steel is the hardest steel for drill bits.False

Tool steels, not high-carbon, are known for maintaining hardness at high temperatures.

Chromoly steel retains strength at high temperatures.True

Chromium and molybdenum enhance toughness and thermal resistance in Chromoly steel.

Is Nickel-Chromium-Molybdenum Steel Suitable for Percussive Drilling?

When I first heard about Nickel-Chromium-Molybdenum steel, I was intrigued by its reputation for strength and resilience. But could it really withstand the punishing demands of percussive drilling?

Nickel-Chromium-Molybdenum steel is ideal for percussive drilling because it combines toughness, impact resistance, and fatigue strength, crucial for enduring intense cyclic stresses.

Understanding Percussive Drilling Demands

I remember when I first saw a percussive drill in action—it was like watching a giant hammer relentlessly battering into the earth, each strike resonating with raw power. Percussive drilling is all about breaking through tough rock layers with rapid, repeated impacts. The tools must be warriors, ready to face harsh conditions without flinching. That's where Nickel-Chromium-Molybdenum steel shines. With nickel boosting its toughness and chromium and molybdenum enhancing its strength and corrosion resistance, it's a formidable contender for such demanding tasks.

Comparing with Other Alloys

Once, during a project, I had to choose between different alloys for a critical drilling operation. It was clear that while Chromium-Molybdenum13 steel had its merits, especially at high temperatures, Nickel-Chromium-Molybdenum steel had the upper hand in resisting fatigue and impact—qualities that are non-negotiable when every strike counts in percussive drilling.

Practical Applications

In practice, I've seen this steel's capabilities firsthand. Imagine the relentless pressure in deep-sea oil drilling, where tools are pushed to their limits. Nickel-Chromium-Molybdenum steel doesn't just hold up; it thrives, maintaining integrity even when the going gets tough. Its ability to withstand the hostile environments often encountered in these settings is a testament to its resilience.

Heat Treatment Effects

I’ve learned that even the best materials can benefit from a little tweak here and there. Through heat treatment processes like tempering, we can fine-tune Nickel-Chromium-Molybdenum steel, optimizing the balance between hardness and toughness. This makes it adaptable, ready to face whatever challenges come its way in dynamic conditions.

Considerations for Selection

When deciding on materials for percussive drilling equipment, I often find myself weighing cost against performance benefits. Sure, Nickel-Chromium-Molybdenum steel might have a higher upfront cost, but its durability can lead to significant savings down the road. This becomes crucial when evaluating the total cost of ownership14, especially in high-intensity operations where reliability can't be compromised.

Nickel-Chromium-Molybdenum steel is ideal for percussive drilling.True

This steel offers excellent toughness and resistance to impact, crucial for percussive drilling.

High-carbon steel is unsuitable for high-temperature drilling.False

High-carbon steel has good wear resistance but can withstand stress, not heat.

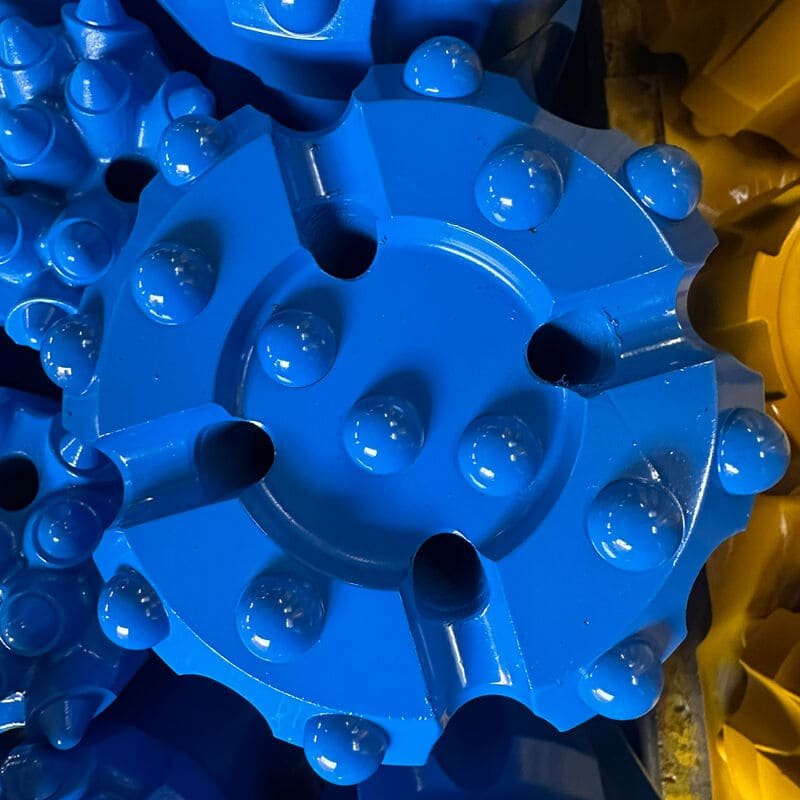

When Should You Consider Tungsten Carbide for Drill Bit Bodies?

Ever found yourself knee-deep in a project, pondering if tungsten carbide is the drill bit hero you need?

I consider tungsten carbide for drill bit bodies when the job requires extreme hardness, outstanding wear resistance, and impressive longevity, especially in abrasive or high-temperature drilling environments.

Understanding Tungsten Carbide Properties

I've always been fascinated by how some materials stand up to the harshest conditions. Tungsten carbide is one of those marvels, renowned for its exceptional hardness and wear resistance. It's like the superhero of materials, especially in challenging drilling environments. It's a composite material that combines tungsten and carbon atoms, bound together with a metallic binder like cobalt or nickel. This gives it superpowers to withstand extreme wear conditions15 and maintain cutting efficiency over time.

When to Opt for Tungsten Carbide

I remember the first time I faced a project where traditional steel bits just couldn’t keep up. The rock was relentless, wearing down everything I threw at it—until tungsten carbide came to the rescue. These drill bits excel in settings where materials like rock or metal cause rapid wear in traditional steel bits. Their toughness makes them perfect for high-abrasion drilling tasks16 and situations involving intense heat, such as oilfield drilling. Plus, their long lifespan can lead to reduced operational costs and fewer bit changes during projects, which is a huge relief when you're on a tight deadline.

Comparing with Other Materials

I've worked with high-carbon and chromium-molybdenum steels too, which are strong and durable. However, tungsten carbide's unique properties make it stand out in certain scenarios. Tool steels offer excellent toughness but can't match tungsten carbide's hardness. Weighing the trade-offs between cost and performance, tungsten carbide becomes the go-to choice when bit longevity outweighs initial expense.

Specialized Applications

In my experience, tungsten carbide isn't just about brute strength—it's about precision too. In industries like aerospace or mining, where exact cuts and minimal downtime are critical, these bits deliver superior results. For those precision tasks, I've found that consulting with experts17 can help determine the specific grade and configuration of tungsten carbide needed for optimal outcomes. It's like getting tailored advice from a seasoned pro who knows exactly what you need to get the job done right.

High-carbon steel is used for drill bit bodies.True

High-carbon steel offers high strength and wear resistance, ideal for drill bits.

Tungsten carbide is a type of steel used in drill bits.False

Tungsten carbide is not a steel; it's a composite material for cutting parts.

Conclusion

Choosing the right steel for drill bit bodies, such as high-carbon, chromoly, tool steel, or tungsten carbide, is crucial for durability and performance in various drilling applications.

-

Explore how high-carbon steel excels under harsh drilling conditions. ↩

-

Learn about high-carbon steel's role in major industries. ↩

-

Discover how heat treatment enhances high-carbon steel properties. ↩

-

Understand why high-carbon steel is a budget-friendly option. ↩

-

Discover how chromium enhances corrosion resistance in steel. ↩

-

Learn about the durability advantages of chromoly steel drill bits. ↩

-

Understand why chromoly steel resists structural failures under stress. ↩

-

Explore how chromoly compares to other alloy steels. ↩

-

Discover how alloying elements enhance tool steel properties. ↩

-

Learn how heat treatment enhances tool steel's durability. ↩

-

Explore diverse industries that rely on tool steel's strength. ↩

-

Understand why tool steel excels over stainless in durability. ↩

-

Explore Chromoly's properties to understand its suitability in comparison. ↩

-

Learn about cost considerations in equipment selection for better decision-making. ↩

-

Discover why tungsten carbide excels in high-wear applications. ↩

-

Learn how tungsten carbide performs in abrasive conditions. ↩

-

Explore tungsten carbide's role in aerospace precision tasks. ↩