Are you struggling with inefficiencies in your drilling operations? Proper maintenance of your DTH drill bit can make all the difference.

To maintain a DTH drill bit effectively, conduct regular inspections for wear, clean after each use, ensure proper handling, and follow lubrication guidelines. These steps enhance performance, extend lifespan, and reduce downtime.

While these basic practices lay the foundation for effective maintenance, there are more advanced techniques and insights that can further optimize your drilling efficiency. Let's delve deeper into these best practices to ensure your operations remain top-notch.

Routine inspections prevent costly drill bit replacements.True

Inspections catch early wear, avoiding expensive failures and downtime.

How Does Routine Inspection Improve Drill Bit Longevity?

Are your drill bits wearing out too quickly? Discover how routine inspections can significantly extend their lifespan.

Routine inspection of drill bits identifies wear and damage early, allowing for timely maintenance that extends the tool's lifespan and efficiency.

The Importance of Early Damage Detection

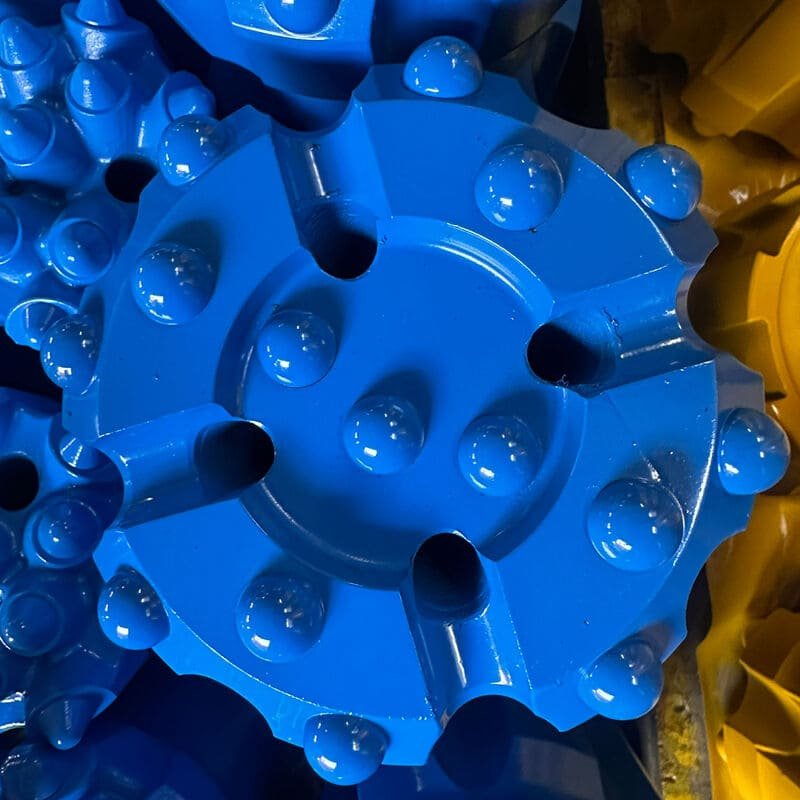

Routine inspections are crucial in spotting early signs of wear and tear on drill bits. Identifying issues like worn carbide buttons, cracks, or blockages early prevents further deterioration and costly replacements. Regular check-ups ensure that minor problems are addressed before they escalate into major failures, which can cause downtime and disrupt operations.

Steps for Effective Inspection

To conduct a thorough inspection, follow these steps:

- Visual Check: Begin with a visual inspection to detect any obvious signs of damage. Look for cracks in the bit body, worn buttons, and debris in the flushing holes.

- Manual Testing: Use tools to test the integrity of the carbide buttons. If they move or show signs of loosening, it’s time for maintenance or replacement.

Maintaining a detailed inspection log1 helps track wear patterns over time, allowing you to predict when a bit might need more intensive maintenance.

Benefits of Routine Cleaning

Regular cleaning, post-inspection, is essential for longevity. After each use, remove dirt and debris from the bit and flushing channels. This prevents blockages that can reduce cooling efficiency and increase wear. Using pressurized air or soft brushes helps maintain the bit's performance by ensuring optimal airflow during drilling.

Enhancing Performance Through Consistent Maintenance

Routine inspections paired with consistent cleaning can notably boost a drill bit's performance. By maintaining a schedule for these checks and cleanings, you ensure that your drilling equipment operates at peak efficiency, reducing operational costs and extending the lifespan of your tools.

Implementing a preventive maintenance plan2 based on these inspections ensures that potential issues are resolved before they affect productivity.

Routine inspections can double drill bit lifespan.True

Routine inspections identify early wear, allowing timely maintenance to extend lifespan.

Ignoring drill bit maintenance has no impact on performance.False

Neglecting maintenance leads to wear, reducing efficiency and increasing costs.

What Role Does Proper Handling Play in Drill Bit Maintenance?

Proper handling of drill bits is essential for maximizing their efficiency and lifespan. Mishandling can lead to premature wear and operational inefficiencies.

Proper handling of drill bits is crucial for maintaining their performance and extending their lifespan. It involves correct operation, appropriate application, and careful storage, ensuring that the drill bit operates efficiently and avoids unnecessary damage.

The Importance of Correct Operation

Operating a drill bit within the manufacturer's recommended parameters is critical. This includes adhering to specified RPMs (revolutions per minute) and feed pressure, which are designed to match the bit's specifications. Exceeding these limits can cause overheating and excessive wear, leading to premature failure.

For instance, if a drill bit designed for softer rock is used on harder surfaces, the increased resistance can overload the bit. This not only diminishes its cutting efficiency but also accelerates wear on the carbide buttons and other components. Therefore, always ensure that the bit is matched to its intended application.

Appropriate Applications and Material Compatibility

Each drill bit is designed for specific materials and conditions. Using a bit outside of its intended application can lead to rapid degradation. A soft rock drill bit3 used on hard granite will wear out quickly due to the increased resistance it encounters.

Additionally, understanding the geology of your drilling site helps in selecting the right bit. Conducting a site analysis ensures that you choose a bit that optimizes penetration rates without compromising structural integrity.

Handling During Transport and Storage

Transporting and storing drill bits correctly is equally important. Bits should be stored in a dry environment to prevent rust and corrosion. Applying anti-corrosion agents can further protect them during long-term storage.

During transport, secure the bits to prevent movement, as excessive jostling can cause physical damage. Use protective covers or cases to shield them from dust and moisture.

Table: Best Practices for Drill Bit Handling

| Aspect | Best Practice |

|---|---|

| Operation | Follow manufacturer RPMs and pressure guidelines |

| Application | Match the bit to appropriate material conditions |

| Transport | Secure bits to prevent damage |

| Storage | Use dry environments with protective covers |

Impact of Handling on Maintenance Costs

Proper handling directly influences maintenance costs by reducing the frequency of repairs and replacements. Bits that are well-maintained through correct handling last longer and perform more efficiently, thereby lowering operational expenses.

Moreover, a maintenance log4 that records proper handling practices can help identify patterns that might require adjustments in technique or equipment choice, further optimizing operational costs.

Using the wrong RPM can cause drill bit overheating.True

Exceeding recommended RPMs leads to overheating and premature wear.

Drill bits do not need protection during transport.False

Unprotected transport can cause physical damage, reducing lifespan.

Why Is Lubrication Crucial for DTH Drill Bits?

Ever wondered why your DTH drill bits don't last as long as expected? Lubrication might be the missing link.

Lubrication is crucial for DTH drill bits because it reduces friction, minimizes wear, and enhances performance. It ensures smooth operation of the hammer and drill string, indirectly prolonging the lifespan of the drill bit itself by preventing damage from heat and abrasion.

The Mechanics Behind Lubrication

Understanding why lubrication is crucial involves delving into the mechanics of DTH (Down-The-Hole) drilling. In this method, the drill bit is directly connected to the hammer, which pounds against the rock. This intense operation generates significant heat and friction.

Without proper lubrication, these components can overheat and wear out rapidly, leading to frequent replacements or repairs. By reducing friction, lubrication helps maintain a lower operating temperature and minimizes the risk of mechanical failure.

Types of Lubricants Used

Choosing the right lubricant is key to effective maintenance. Here are some common types used in DTH operations:

- Grease: Often used for its ability to adhere well under high pressures and temperatures.

- Oil: Provides excellent penetration into tight spaces and is often used in conjunction with grease.

- Specialty Additives: Anti-wear and extreme pressure additives can enhance the protective qualities of the primary lubricant.

For more details on choosing the right lubricant5, it's essential to consider factors like environmental conditions and specific equipment requirements.

Benefits Beyond Friction Reduction

While reducing friction is a primary function, lubrication offers additional benefits:

- Corrosion Prevention: Lubricants form a barrier against moisture, preventing rust and corrosion that could compromise structural integrity.

- Dirt and Debris Repellent: A well-lubricated surface resists dust and particles that can cause abrasive wear.

For insights on corrosion prevention6, understanding these additional benefits can significantly extend the life of your equipment.

Implementing an Effective Lubrication Strategy

To ensure your DTH drill bits are always in optimal condition, consider these steps:

- Scheduled Lubrication: Establish a routine based on operational hours or usage cycles. Consistent application prevents lapses that could lead to damage.

- Monitoring Systems: Utilize technology to monitor lubricant levels and quality in real-time.

- Training: Ensure that your maintenance team is well-versed in applying lubricants correctly to avoid over-lubrication or under-lubrication issues.

By implementing an effective strategy7, you not only enhance performance but also ensure a longer lifespan for your tools.

Lubrication reduces DTH drill bit wear.True

Lubrication minimizes friction, reducing wear and extending drill bit life.

Oil is not used in DTH drilling lubrication.False

Oil is used for penetration and works with grease in DTH operations.

When Should You Consider Reconditioning a Drill Bit?

Is your drill bit underperforming? Learn when reconditioning can revive its efficiency and extend its life.

Recondition a drill bit when it shows significant wear but remains structurally sound. This involves professional services that replace worn buttons, repair cracks, and restore its original profile, extending its lifespan and improving performance.

Signs of Wear Indicating the Need for Reconditioning

Recognizing the right time to recondition your drill bit8 can save time and money in the long run. Here are clear indicators:

- Worn or Dull Carbide Buttons: When the cutting edges become rounded or dull, affecting penetration rates.

- Surface Cracks: Small cracks on the bit body or around the button areas, which can lead to larger failures if not addressed.

- Decreased Penetration Rates: A noticeable drop in drilling speed could indicate worn components.

Benefits of Professional Reconditioning Services

Opting for professional reconditioning services can bring your drill bit back to optimal performance. Services typically include:

- Button Replacement: Renewing worn carbide buttons to regain cutting efficiency.

- Crack Repairs: Utilizing specialized techniques to fix minor cracks, preserving structural integrity.

- Profile Restoration: Ensuring the drill bit's profile and angles are reset for best performance.

| Service | Benefit |

|---|---|

| Button Replacement | Restores cutting efficiency |

| Crack Repairs | Prevents structural failure |

| Profile Restoration | Optimizes penetration and lifespan |

Factors Influencing the Decision to Recondition

Several factors should be considered before deciding to recondition a drill bit9:

- Cost vs. Replacement: Compare the cost of reconditioning with purchasing a new bit. Often, reconditioning is more economical, especially for high-value bits.

- Bit Condition: Only bits that are structurally sound should be reconditioned. Severe damage or excessive wear might warrant replacement.

- Drilling Conditions: Consider whether the reconditioned bit will be suitable for your drilling needs, especially if conditions have changed since its initial use.

How Often Should Reconditioning Be Considered?

Regular maintenance logs can help determine the frequency of reconditioning10:

- Routine Checks: Integrate inspections into your maintenance schedule to catch wear early.

- Usage Intensity: High-intensity applications may require more frequent reconditioning.

- Historical Performance: Use past performance data to predict when reconditioning might be necessary.

Keeping a detailed maintenance log ensures that you can anticipate reconditioning needs effectively.

Reconditioning a drill bit can restore its original profile.True

Professional services restore the bit's profile for optimal performance.

A severely damaged drill bit should always be reconditioned.False

Severely damaged bits may need replacement, not reconditioning.

Conclusion

Regular maintenance of DTH drill bits boosts efficiency and reduces costs. Start integrating these strategies today to enhance your drilling operations.

-

Learn to effectively track wear patterns and schedule timely maintenance.: To inspect your drill bits, start by removing the bit from the drill while following safety guidelines. Visually inspect the cutting edges and ... ↩

-

Understand how preventive maintenance can optimize tool performance.: A drill rig requires daily and weekly maintenance to ensure that the unit operates as intended and does not result in injury to workers and costly project ... ↩

-

Learn about choosing the right drill bit for granite drilling.: You will want an SDS drill, and so an SDS drill bit. Any masonry bill will work, but using an SDS drill is about 10x faster than a normal hammer drill. ↩

-

Discover how a maintenance log optimizes drill bit lifespan.: Sharpening your drill bits will help prolong their lifespans and maintain their precise edges. They can be sharpened with a drill sharpener, a ... ↩

-

Learn about various lubricants to optimize your DTH drill bit's performance.: Inpol Lube is an environmentally friendly lubricant for DTH hammers. This non-toxic compound is very durable and economical and is available in 10 oz. ↩

-

Discover methods to protect your equipment from rust and corrosion.: Many of the individual parts of complex drilling equipment are usually electrically isolated by paint coating and thereby not intended for cathodic protection ( ... ↩

-

Explore strategies to maximize equipment efficiency and lifespan through lubrication.: 1. Assessment/Benchmarking · 2. Organization and Planning · 3. Identification · 4. Cleanliness Control · 5. In-plant Dispensing · 6. Grease Lubrication Tools · 7. ↩

-

Learn the ideal timing for drill bit reconditioning.: You should change or sharpen your twist drill when it gets dull. Signs of a dull drill are excessive heat, slow cutting rate, needing more ... ↩

-

Discover how professional services enhance drill bit performance.: Benefits of Reconditioning: · Saving on cost: PCD tools have an initial high-cost investment compared to traditional solid carbide cutting tools. ↩

-

Find out the recommended frequency for drill bit reconditioning.: You should change or sharpen your twist drill when it gets dull. Signs of a dull drill are excessive heat, slow cutting rate, needing more ... ↩