Selecting the best drilling technique is crucial for project success. Choosing the wrong method may lead to failure.

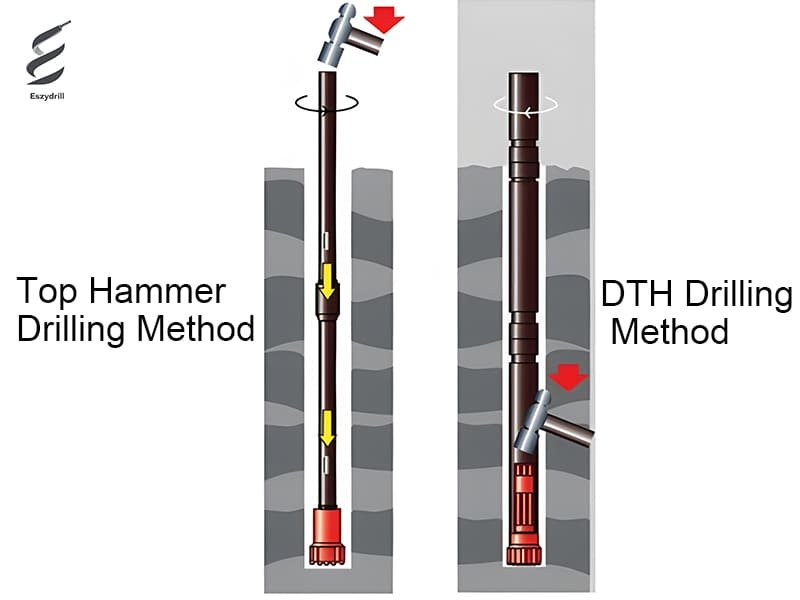

DTH hammer drilling performs very well in deep, hard rock situations. This method transfers energy directly to the drill bit. Top Hammer drilling works better for shallow, cohesive formations. It offers faster penetration rates. Both methods serve specific project needs. They affect both efficiency and cost.

This offers a quick glimpse. Examining the details could transform your project planning. Every drilling method works differently. It provides unique benefits and poses different challenges. Understand these differences. Whether you need to drill deep in a rough mountain or on a flat construction site, each method serves various purposes. Determine which method suits your needs. Choose wisely.

DTH drilling is best for deep, hard rock formations.True

DTH drilling offers direct energy transfer, ideal for deep, hard rocks.

Top Hammer drilling is slower than DTH for shallow formations.False

Top Hammer drilling is faster in shallow, cohesive formations.

How Does Impact Force Location Affect Drilling Efficiency?

Do you ever think about how the correct drilling technique might save you both time and money?

The location of impact force influences drilling efficiency by guiding energy transfer. In DTH drilling, energy is applied directly at the bit. This method really reduces energy loss. In Top Hammer drilling, force moves through rods. Energy may reduce, especially in deeper holes. Efficiency might decrease in these situations.

The Science of Impact Force in Drilling

I remember my first deep dive into drilling; it felt like entering a detailed dance where each step really mattered. In drilling operations, the spot where impact force hits may be the key to a smooth project or a problematic one. With Down-The-Hole (DTH)1 drilling, the hammer sits right above the bit, like a drummer striking the right note. This position saves energy and transfers it efficiently to the rock below.

When I first tried Top Hammer2 drilling, the impact force starting at the top challenged my patience and accuracy. Energy travels down through each rod and loses some power. This loss becomes more noticeable as you drill deeper.

Comparing DTH and Top Hammer Efficiency

To better understand how these methods compare:

| Drilling Method | Impact Force Location | Energy Transfer Efficiency | Best Application Depth |

|---|---|---|---|

| DTH Drilling | Direct at bit | High | Beyond 20 meters |

| Top Hammer | At top of drill string | Variable | Less than 25 meters |

With DTH drilling, I have seen projects with excellent efficiency at great depths. The hammer close to the bit means even really hard rocks did not stop us. On the other hand, Top Hammer drilling is less efficient for deep holes because of energy loss over long rods. But it works very well for surface tasks requiring speed and mobility.

Practical Applications and Considerations

Imagine drilling in tough rock conditions over 30 meters deep. From my experience, DTH drilling really helps to keep energy efficient over such long distances. However, for a surface project where speed matters, Top Hammer systems might work best despite losing some energy.

Understanding these dynamics doesn't just affect tool choice but also project planning. DTH tools are perfect for hard and rough rock formations3. Meanwhile, Top Hammer tools shine in soft formations where speed is critical.

Evaluating these factors is vital—not just for lowering operational costs—but also for reducing environmental impact and managing noise well. Every decision affects not only profits but also the environment and nearby communities.

DTH drilling applies impact force directly at the bit.True

In DTH drilling, the hammer is positioned above the bit, minimizing energy loss.

Top Hammer drilling is most efficient beyond 20 meters depth.False

Top Hammer drilling is less efficient for deeper holes due to energy dissipation.

Which Drilling Method is Better for Deep Holes?

Selecting the correct drilling method for deep holes is not only technical. It is also strategic. This choice affects efficiency and costs. Let's examine which method might suit you best.

Down-The-Hole (DTH) drilling is often popular for drilling deep holes. It transfers energy efficiently. It keeps the hole straight even at great depths. Top Hammer drilling usually works better for shallower depths.

Understanding Drilling Methods for Deep Holes

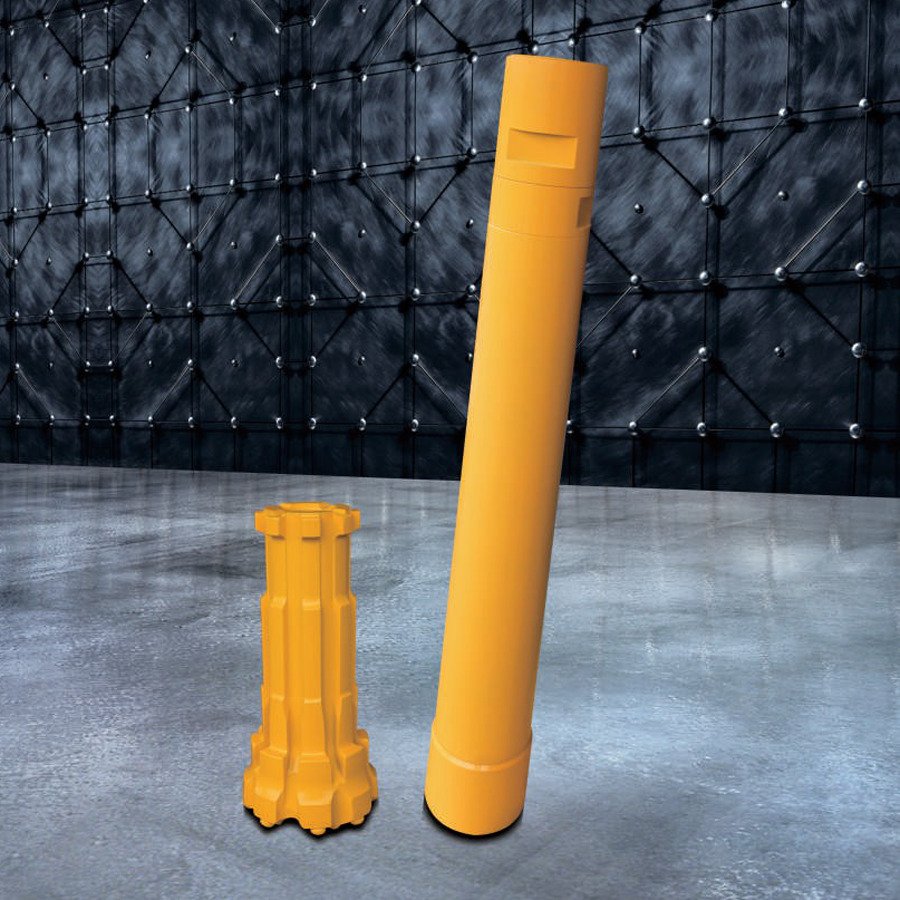

Drilling deep holes involves choosing between DTH drilling4 and Top Hammer methods. Each method has its unique benefits, and the choice often depends on what the project needs.

Energy Transfer Efficiency

-

DTH Drilling: I remember working on a tough site with deep, hard rock. DTH Drilling helped a lot there. The force hits the rock directly at the bottom, reducing energy loss as it travels through the drill string. This suits deep depths where precision must be high. Power and accuracy are vital here.

-

Top Hammer Drilling: Creates force at the top, causing energy to dissipate over long distances. This makes it less effective for deep holes but great for surface-level tasks where quick penetration rates are useful.

Depth Capability and Hole Size

| Method | Typical Depth | Hole Diameter |

|---|---|---|

| DTH Drilling | Beyond 20 meters | 100 to 254 mm |

| Top Hammer | Less than 25 meters | Up to 127 mm |

DTH drilling maintains straight and precise holes over long distances, keeping everything aligned matters a lot in deep drilling.

Suitability for Rock Formations

-

DTH Drilling: Performs well in hard and rough conditions. It handles different geological formations well, making it my choice for tricky underground terrains.

-

Top Hammer Drilling: Excels in stable rock formations with high penetration rates in cohesive formations. Speedy drilling is possible here.

Cost Considerations

Budget plays an important role in my decisions:

-

DTH Drilling: Costs more upfront due to its complexity but is efficient for deep drilling, which may lower operational costs over time.

-

Top Hammer Drilling: Has lower initial costs, making it attractive for smaller projects; however, consumable wear could raise costs later.

Environmental Impact

Noise matters on many sites I've handled:

-

DTH Drilling: Is quieter, which is helpful near noise-sensitive areas.

-

Top Hammer Drilling: Is louder and might disturb nearby environments.

Considering these aspects helps me select the most effective method for my project's needs. For detailed information on drilling tools, a comprehensive product guide5 is useful.

DTH drilling is more efficient for deep holes than Top Hammer.True

DTH drilling applies force directly at the bottom, reducing energy loss.

Top Hammer drilling is ideal for hard rock formations.False

Top Hammer is best for stable formations, not necessarily hard ones.

Which Rock Formations Are Best for DTH or Top Hammer Drilling?

Deciding between DTH and Top Hammer drilling feels like choosing the correct tool. The choice depends on the rock type. Matching the method to the rock type truly matters.

DTH drilling suits very hard and abrasive rocks with a hardness over 200 MPa. Top Hammer performs well in cohesive and stable formations with hardness below 200 MPa.

Understanding the Impact of Rock Hardness

When I started drilling, rock hardness seemed confusing. Soon, I learned it was very important for choosing between DTH and Top Hammer methods. DTH drilling feels like using a big hammer for tough rocks. It works really well for rocks over 200 MPa by focusing power at the bottom of the hole. This accuracy is unmatched and improves work efficiency.

In contrast, Top Hammer drilling speeds through softer rocks under 200 MPa. It works great for stable and shallow projects. The action from the top of the drill string helps move the earth faster.

Depth and Hole Size Considerations

| Criteria | DTH Drilling | Top Hammer Drilling |

|---|---|---|

| Depth | Beyond 20 meters | Less than 25 meters |

| Hole Size | 100-254 mm+ | Up to 127 mm |

When I plan a project, DTH drilling becomes essential for deep, straight paths where precision is very important. In contrast, Top Hammer drilling is the best choice when quick surface-level tasks are needed.

Geological Conditions and Applications

For varied geological conditions, DTH drilling6 is as versatile as my multi-tool. It suits mining or construction projects with unexpected rock hardness issues. Its flexibility allows me to handle surprise rock layers easily.

For predictable challenges like limestone or sandstone, Top Hammer drilling is trustworthy. It delivers consistent penetration and reduces equipment wear.

Economic and Environmental Factors

Economic factors influence my decisions a lot. DTH drilling might cost more at first but usually saves money later with its great efficiency in tough settings.

Also, noise levels matter. In cities or sensitive areas, DTH’s quieter operation7 really helps. Less noise leads to fewer complaints and happier neighbors.

By thinking about these factors, I match each project with the best drilling method, achieving efficiency and saving money every time.

DTH drilling is best for rocks over 200 MPa.True

DTH drilling excels in hard, abrasive formations exceeding 200 MPa.

Top Hammer drilling suits depths over 25 meters.False

Top Hammer drilling is ideal for depths less than 25 meters.

How Do Costs and Equipment Complexity Compare?

Have you ever felt overwhelmed by the costs and complexity of picking equipment for your project?

High costs and equipment complexity are closely linked. More complex equipment usually has higher initial costs and maintenance. It probably helps with efficiency and precision. This affects long-term financial results.

Initial Investment vs. Long-Term Costs

When evaluating equipment, it's crucial to differentiate between initial costs8 and long-term operational expenses. High-tech equipment usually requires a significant upfront investment due to advanced technology and engineering. However, it often provides better performance and efficiency over time.

| Equipment Type | Initial Cost | Maintenance Cost |

|---|---|---|

| Simple Equipment | Low | Moderate to High |

| Complex Equipment | High | Low to Moderate |

For example, in drilling applications, DTH drilling systems9 have higher initial costs but save money in deep drilling scenarios due to their efficiency. Simpler systems may need many replacements, increasing long-term expenses.

Efficiency and Precision

Complex machines often provide precision and efficiency. This can lead to quicker project completion, cutting labor costs and downtime. Industries such as manufacturing or aerospace engineering10 benefit greatly from high-precision tools that might be complex but deliver trustworthy results.

- Example: Automated CNC machines have detailed programming that lowers errors and waste, saving money in the long run compared to manual machining processes.

Maintenance and Training Costs

More complex machines may require more maintenance and special training. It's important to think about the availability of skilled workers and training resources11 when buying complex systems. Training increases initial costs but can improve efficiency later by lowering error rates.

- Consideration: Investing in thorough training helps balance these costs by enhancing operational efficiency.

Case Study Comparison

Think about a business deciding between basic drilling rigs and advanced hydraulic rigs. The advanced option requires a higher upfront investment but offers greater durability and speed.

| Factor | Basic Rig | Hydraulic Rig |

|---|---|---|

| Cost | Lower initial, higher ongoing | Higher initial, lower ongoing |

| Complexity | Low | High |

| Performance | Adequate for simple tasks | Superior for complex tasks |

| Maintenance | Frequent | Minimal |

Every business must evaluate these elements based on its projects and budget constraints to find the most cost-effective choice.

Complex equipment has lower maintenance costs.True

Complex equipment often requires less frequent maintenance due to advanced design.

Simple equipment offers higher initial investment savings.True

Simple equipment typically involves lower upfront costs, saving initial investment.

How Do Different Drilling Methods Affect the Environment?

Curious about how drilling affects Earth? Explore the environmental impacts of various techniques. These range from noise pollution to harmful emissions.

Different drilling methods affect the environment in their own ways. They mostly cause noise, disturb habitats and release emissions. For example, Down-The-Hole (DTH) drilling produces less noise. This method might, however, consume more energy. Top Hammer drilling creates more noise and really disrupts wildlife a lot. Wildlife feels disturbed.

Noise Pollution

Noise pollution is a big problem with drilling. DTH drilling is quieter because the action happens deep underground. This makes it better for noise-sensitive places12 like cities or areas with a lot of wildlife. Top Hammer drilling is much louder because the work takes place at the surface, potentially disturbing nearby fauna.

Emissions and Energy Consumption

Drilling requires a lot of energy. DTH drilling uses energy more wisely as it sends power directly to the drill bit, which generally results in lower energy use. However, the technology is more complex and expensive, which probably increases carbon emissions13.

Energy Comparison Table

| Drilling Method | Energy Efficiency | Potential Emissions Impact |

|---|---|---|

| DTH Drilling | Higher | Lower |

| Top Hammer | Lower | Higher |

Habitat Disruption

I’ve seen many sites where habitat damage was clear. Top Hammer drilling often causes a lot of land disturbance and vegetation removal, especially in thick forests. On the other hand, DTH drilling14 tries to reduce surface impact, which is very good for protecting nature.

Waste Management

Handling waste is really important. Drilling creates lots of debris that needs proper disposal to avoid harming the environment. Top Hammer methods might require more recovery work compared to DTH methods15, which disturb the surface less.

Water Usage and Contamination

Water really is life, right? Some drilling methods need water for cooling or lubrication, potentially straining local water supplies. Careful management is essential to stop contamination or depletion during drilling operations—something I always consider when planning these projects.

DTH drilling produces less noise pollution.True

DTH drilling's percussive action occurs at the bottom, reducing noise.

Top Hammer drilling is more energy efficient.False

Top Hammer has lower energy efficiency compared to DTH drilling.

Conclusion

DTH hammer drilling excels in deep, hard rock applications with efficient energy transfer, while Top Hammer drilling is faster for shallow formations. Each method has unique advantages and challenges.

-

Learn about DTH drilling's direct impact force application, ensuring efficient energy transfer. ↩

-

Understand how energy travels in Top Hammer drilling and its effects on deeper holes. ↩

-

Explore why DTH tools excel in maintaining efficiency in challenging geological conditions. ↩

-

Learn why DTH drilling excels in deep hole applications, including efficiency and hole straightness. ↩

-

Explore detailed information on selecting the right drilling tools and equipment for deep hole projects. ↩

-

Explore more about geological conditions suitable for DTH drilling to enhance project planning. ↩

-

Learn how noise levels differ between DTH and Top Hammer drilling, especially important for urban projects. ↩

-

Explores how initial equipment investment impacts long-term operational expenses. ↩

-

Provides insights into why DTH systems are cost-effective for deep drilling. ↩

-

Highlights the advantages of precision machinery in improving aerospace manufacturing. ↩

-

Details available resources for training personnel on complex machinery. ↩

-

Learn how DTH drilling's reduced noise can benefit wildlife and sensitive environments. ↩

-

Explore how different drilling methods compare in terms of carbon emissions. ↩

-

Understand why DTH drilling may result in less habitat disruption. ↩

-

Discover effective waste management practices for DTH drilling methods. ↩