Ever thought about drilling quickly and accurately through tough rock?

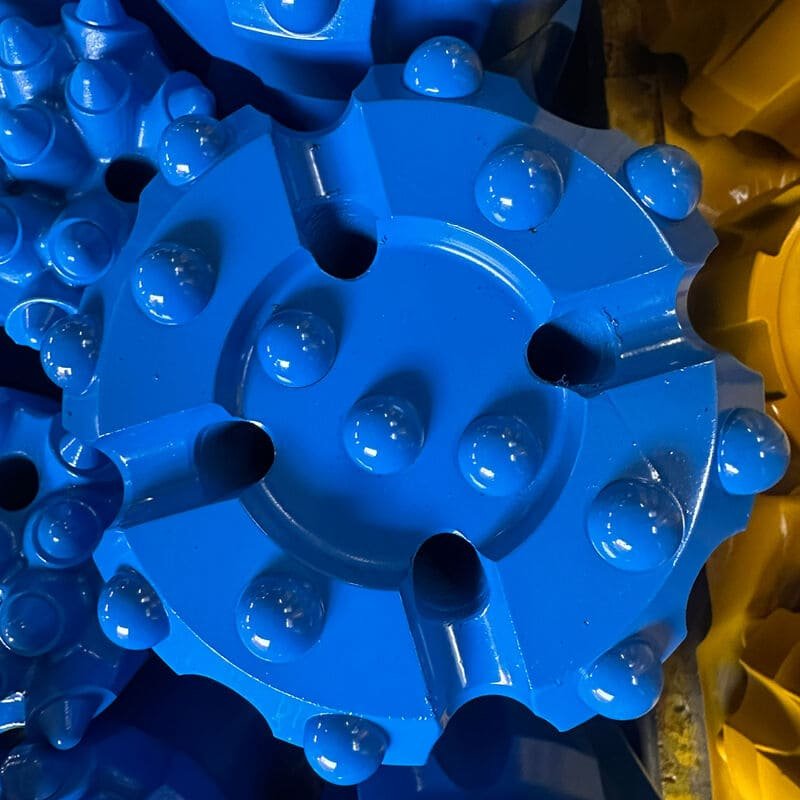

Drop Center Face DTH Drill Bits work well on softer to medium-hard rock. Speed and centering really matter. These bits offer stability. Precision is vital. Ideal for tough construction and mining jobs.

Knowing when to use Drop Center Face DTH Drill Bits really improves your project's efficiency. Picture yourself on a strict deadline in a tough building zone, where time truly matters. The correct bit speeds up drilling. It also provides stability and accuracy for success. In mining or building a tall tower, these bits perform well when under pressure. Let's explore specific situations where they truly matter.

Drop Center Face DTH Bits are best for hard rock formations.False

They are ideal for softer to medium-hard rocks, not hard formations.

These bits improve debris removal in drilling projects.True

Their design enhances debris removal, aiding efficiency and precision.

Why Are Drop Center Face DTH Drill Bits So Effective?

Do you ever ask yourself why Drop Center Face DTH drill bits are favored for difficult drilling situations?

Drop Center Face DTH drill bits have a special recessed center design. This design increases penetration speed. It also helps to keep drilling on course. These drill bits work well at removing rocks effectively. Vibrations lessen significantly with their use. Adaptability is a key feature. Different ground conditions are no problem for them.

Faster Drilling Rates

Picture yourself on a drilling job where every minute matters. These bits, with their special center shape, cut through softer to medium-hard rocks quickly. I once worked on a site that had different rock types and the speed of these bits was amazing. Breaking rock faster allowed us to meet tight deadlines without losing quality.

| Condition | Benefit |

|---|---|

| Soft rock | Faster penetration |

| Medium-hard rock | Efficient breakage |

Important Centering Ability

Staying centered is crucial in drilling, especially when the ground is tough to work with. The design focuses power right in the center. On one project I remember well, this feature saved us from many problems by keeping accuracy in unstable areas.

- Applications: Tunneling, foundation drilling

- Advantages: Better straightness, exact borehole location

Quick Drill Cuttings Removal

Have you ever dealt with drill bits getting blocked? It’s really annoying. This smart bit design lets debris leave easily, thanks to the special center shape and raised edges. This feature turned the tide on a difficult site where clogging was a regular issue.

| Feature | Impact |

|---|---|

| Special center shape | Better debris removal |

| Raised edges | Prevents clogging |

Adaptable in Changing Ground Conditions

If you have experienced a drilling site with mixed rock layers, you'll value the flexibility of these bits. They adjust really well to changes in rock hardness and arrangement, making them essential for tricky projects. Be it construction or mining, they are always ready for surprise conditions underground.

- Industries: Construction1, Mining2

- Benefits: More flexibility, great adaptability

Lowering Bit Bounce and Vibration

In soft grounds, bit bounce and vibration are annoying. But the Drop Center design reduces vibrations, giving a smoother drilling experience. I’ve seen that this not only increases equipment life but also makes the job easier for operators like me.

- Effect: Longer equipment life, better operator comfort

- Feature: Vibration lowering system

For those interested in how these designs improve different conditions, I suggest checking out resources on drilling efficiency3 and equipment stability4.

Drop Center bits improve penetration in soft rock.True

The recessed center design enhances penetration rates in softer formations.

Drop Center bits are ineffective in uneven grounds.False

They maintain position well, making them effective in unstable grounds.

How Do Drop Center Bits Improve Drilling Efficiency?

Do you ever think about how a small change in design impacts your drilling skills? A tiny adjustment often leads to big results. Designs play a big role in how you perform. One small tweak surprises you with its effects. It really transforms how you approach drilling.

Drop center bits drill effectively by increasing speed and hitting the right spot. They also clear away waste better. They work well in different types of rock and reduce shaking. This leads to steady drilling.

Improved Penetration Rates

I remember the first time I saw drop center bits on a drilling project. It was like watching an expert artist skillfully carve into rock. These bits are designed to increase the speed of drilling. Their unusual shape helps them break rock quickly and well, especially with softer to medium-hard types of rock that used to slow us down.

| Feature | Benefits |

|---|---|

| Penetration Speed | Faster project completion |

| Rock Suitability | Ideal for softer to medium-hard formations |

Precise Centering

One project had such uneven ground, it felt like balancing on a tightrope in a storm. There, the drop center design5 truly helped us. It focused energy towards the middle, keeping the drill straight. This was crucial for our tunneling and foundation work.

Effective Debris Removal

I have seen how blocked drills can stop a project suddenly. Drop center bits do well in removing debris. Their sunken center creates a path that easily pushes debris away. This keeps a clear contact between bit and rock and prevents wear.

- Flushing Efficiency: Better debris removal cuts down wear.

- Operational Stability: Clearer contact betters drilling efficiency6.

Adaptability in Different Ground Conditions

These bits really stand out for their flexibility. I faced changing rock hardness and these bits managed with ease. They suit places like construction sites, quarries, and mines where ground changes often.

Stability in Soft Rock

Drilling in soft rock is like trying to draw on jelly. Bits can bounce and vibrate badly. The drop center shape keeps the bit steady, allowing smoother drilling and easing pressure on the rig.

Comfort in Operation: Less shaking improves operator safety7 and extends equipment life.

From my experience, drop center bits are a flexible choice. Whether you need quick drilling or steady work, these bits have shown their value by keeping both efficiency and precision high.

Drop center bits increase drilling speed in soft rocks.True

Their design boosts penetration rates, especially in softer formations.

Drop center bits are ineffective in debris removal.False

They excel at flushing efficiency, preventing clogging and enhancing contact.

Which rock types are best for drop center bits?

Curious about where drop center bits really excel? I can share some insights from my drilling experiences.

Drop center bits excel in softer to medium-hard rocks such as limestone and shale. Their design increases penetration and keeps everything aligned. This holds true even in difficult ground conditions.

Understanding Rock Types for Drop Center Bits

When exploring drilling tools, understanding rock types changes everything. Imagine being at a construction site and the ground is unpredictable. Knowing rocks and tools becomes essential. Here's a breakdown:

| Aspect | Description |

|---|---|

| Faster Drilling Speeds | On one project, speed was very important. We drilled through limestone and drop center bits really increased our drilling speed. It was like cutting through butter - so smooth and fast. These bits help with speed, which probably saves time on fast-moving projects. Learn more8 |

| Steady Drilling on Uneven Ground | Drilling on tricky ground can feel impossible. I've experienced it. Drop center bits keep the drill steady, staying straight in rough areas, which is very helpful. This is really important in geological formations where straight holes are hard to achieve. Explore geological formations9 |

| Efficient Debris Clearing | Debris can stop progress quickly. The design of drop center bits clears debris effectively, reducing annoying blockages. In different ground conditions, where debris is unpredictable, these bits keep operations smooth. Discover varied conditions10 |

Understanding these details has been important for me and can be for you too. Knowing how rock types and drop center bits work together can change your drilling approach to become really efficient and save money. Once you understand this synergy, it feels like a secret advantage in your work.

Drop center bits are most effective in limestone.True

Drop center bits excel in soft sedimentary rocks like limestone.

Granite is ideal for drop center bit usage.False

Drop center bits are less effective in hard rocks like granite.

Why Should You Invest in Enhanced Debris Removal?

Ever feel like debris is a constant struggle at your construction site? It’s not just a mess. It’s a chance for change!

Better debris removal raises safety by lowering risks. Efficiency climbs by reducing downtime. Waste is better managed, which helps sustainability. These advantages are crucial for successful building and renovation work.

Safety Improvements

I remember visiting a site once where debris scattered everywhere, like traps waiting for someone to fall. Quick debris removal changes everything. Clearing waste fast lowers the risk of accidents. It protects people on site and eases managers' worries about legal issues. I read a study on construction safety11 showing that good debris management greatly reduces injuries.

Operational Efficiency

Clutter slows projects down. At my first construction job, I saw how crucial it was to keep spaces clear. Quick debris removal keeps everything running smoothly. It allows easy transitions between project steps. Imagine the relief when quicker cleanup lets resources start faster, as seen in this project timeline example12.

Environmental Sustainability

Being eco-friendly goes beyond words - it is a duty. By using good debris removal practices, we sort and recycle waste better. This greatly reduces our ecological impact. Industry reports, like those in industry reports13, show proper waste management lowers costs and keeps regulations in check.

Compliance and Regulations

Understanding regulations feels like reading a book with missing parts. Thankfully, good debris removal meets these requirements. It avoids expensive fines and project delays. Keeping a compliance checklist14 handy helps stay on track with rules.

Cost Effectiveness

At first, spending on debris removal systems might seem costly, but long-term savings are clear. I once prepared a detailed cost analysis report15 that demonstrated how these savings add up over time.

| Advantage | Benefit Description |

|---|---|

| Safety | Reduces accident risks on-site |

| Efficiency | Streamlines operations, minimizing downtime |

| Sustainability | Improves waste management, aiding environmental goals |

| Compliance | Meets regulatory requirements, avoiding penalties |

| Cost Effectiveness | Reduces long-term project costs through strategic waste management |

Enhanced debris removal reduces on-site accident risks.True

Efficient debris management decreases hazards, preventing accidents.

Proper debris removal increases project costs significantly.False

Long-term savings from reduced fines and efficient operations lower costs.

Why Is Bit Centering Important for Precision Drilling?

Drilled a hole and missed the mark? Bit centering helps. Every hole aligns perfectly. Very important for precise work.

Bit centering holds great importance in precision drilling. Correct alignment of the drill bit reduces deviation. Precise boreholes result from this alignment. Many projects require this level of exactness. Accurate dimensions and low mistakes matter a lot.

The Role of Bit Centering in Precision Drilling

I recall my first big drilling project very clearly. My team and I stood there, understanding that even a tiny shift in our drill bit might cause problems. Bit centering16 is about keeping the drill bit correctly placed during work. This method is very important when exactness is key - in places like construction and mining. Exact drill hole placement decides the project's success.

Benefits of Proper Bit Alignment

We experienced much equipment damage when our bits weren't centered well. It’s surprising how a small tweak leads to big results: less wear, quicker drilling, and increased stability. Perfect bit alignment means the drill's energy hits precisely, speeding up the process and lengthening tool life.

Table: Impact of Bit Centering on Drilling Efficiency

| Factor | Without Centering | With Centering |

|---|---|---|

| Drill Deviation | High | Low |

| Equipment Wear | Increased | Reduced |

| Operational Stability | Low | High |

| Penetration Rate | Slower | Faster |

Application in Varying Conditions

I’ve worked in difficult areas with uncertain ground conditions. Bit centering17 becomes even more vital. It’s like having a reliable guide through different rock hardness and shapes. This method stands out in tunneling and foundation drilling - keeping things steady despite geological changes.

Technical Aspects of Bit Centering

Picking the right drill bit design is important. Features like special centers or cutting edges direct energy to keep it steady, reducing drift. Knowing these details helps me pick the right tools, so we’re always ready for precise work.

Using bit centering techniques18 has improved our work and supports eco-friendly methods by using resources wisely and lowering the environmental effect. By employing precise drilling methodologies, we drill smarter and more responsibly. Looking back, bit centering isn’t just a technique - it changes the game.

Bit centering reduces equipment wear in drilling.True

Proper bit alignment minimizes stress and vibrations, reducing wear.

Drill deviation is higher with bit centering.False

Bit centering minimizes deviation by maintaining drill alignment.

Conclusion

Drop Center Face DTH drill bits excel in softer to medium-hard rock, enhancing drilling speed, accuracy, and debris removal, making them ideal for construction and mining applications.

-

Explore the role of Drop Center bits in enhancing construction efficiency, especially in tunneling and foundation work. ↩

-

Understand how these drill bits optimize mining operations through improved penetration and debris removal. ↩

-

Learn about design features that enhance overall drilling efficiency and speed. ↩

-

Discover how these bits contribute to reducing vibration and improving rig stability. ↩

-

Explore detailed benefits of drop center design, focusing on improved centering and energy distribution. ↩

-

Discover strategies to enhance drilling efficiency with innovative bit designs. ↩

-

Learn how reduced vibration impacts operator safety and equipment lifespan. ↩

-

Explore how drop center bits enhance drilling speed and efficiency in soft rock formations like limestone. ↩

-

Discover why drop center bits maintain stability and alignment in challenging geological formations. ↩

-

Learn about the design features of drop center bits that facilitate efficient debris clearance. ↩

-

Discover how effective debris management improves safety and reduces on-site injuries. ↩

-

Learn how efficient debris clearance accelerates project phases. ↩

-

Explore how sustainable practices reduce project footprints. ↩

-

Ensure your project meets all necessary regulatory standards. ↩

-

Examine the financial benefits of investing in advanced debris management. ↩

-

This link provides a deeper understanding of bit centering techniques and their applications in various drilling scenarios. ↩

-

Learn about different types of drill bits designed specifically to maintain centering and improve drilling precision. ↩

-

Discover the design elements that facilitate bit centering, crucial for selecting the right tools for your project. ↩