Have you ever pondered how the shape of a tiny button could revolutionize your drilling success?

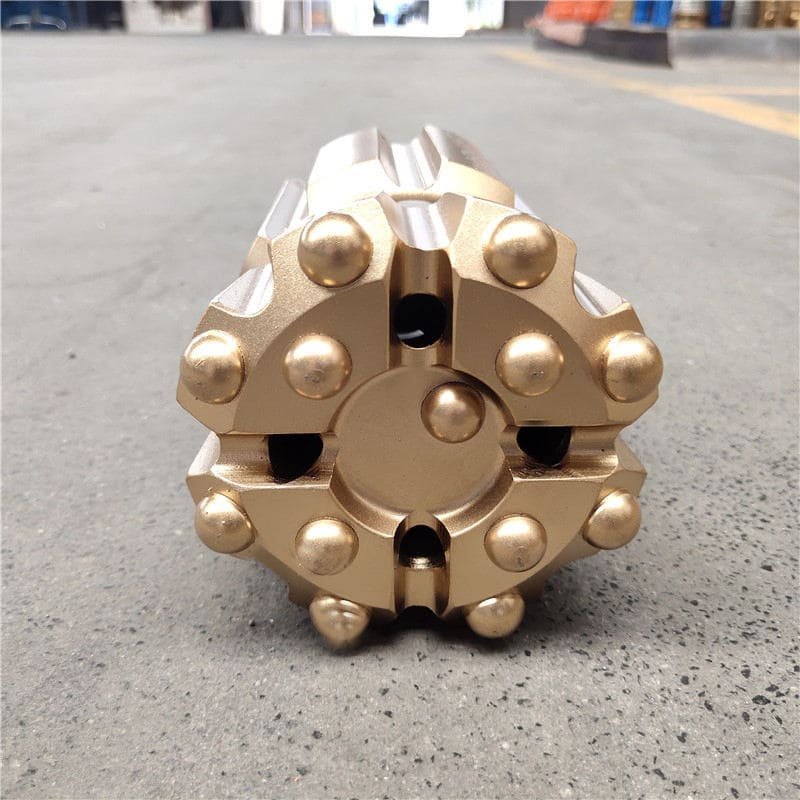

The shape of carbide buttons on DTH drill bits can significantly affect drilling efficiency by impacting penetration rates, wear resistance, and overall performance. Ballistic buttons excel in medium-hard rocks with high penetration, while spherical buttons offer durability in abrasive conditions. Choose based on rock type and desired results.

Understanding the nuances of these button shapes can be a game-changer. I remember the first time I tackled a particularly stubborn patch of medium-hard rock. Switching to ballistic buttons transformed my approach, cutting through with surprising ease. It's experiences like these that make me appreciate the importance of button selection.

In this post, let's explore the world of carbide button shapes together. I'll share practical insights and tips I've picked up over time, guiding you to make informed choices for optimizing your drilling equipment. Whether you're dealing with soft or hard rock formations, knowing which button to choose can save time, effort, and wear on your gear.

Spherical buttons have longer service life in abrasive rocks.True

Spherical buttons are known for their durability in abrasive conditions.

Ballistic buttons perform better in softer rock formations.False

Ballistic buttons are more effective in medium-hard to hard rock formations.

What Makes Spherical Buttons Stand Out?

Ever wondered why spherical buttons are a go-to choice in industries like mining and fashion?

Spherical buttons shine with their impressive penetration rates in softer to medium-hard rock formations and their durability in abrasive conditions, making them a reliable choice across various applications.

Versatility Across Applications

Spherical buttons are celebrated for their versatility in a variety of applications1, from mining drills to construction tools, and even as chic fasteners on designer coats. Their unique shape allows them to glide through different materials with ease, providing reliable performance across diverse scenarios.

Enhanced Penetration Rates

When I first learned about drilling, I was amazed at how spherical buttons maintain high penetration rates. Picture this: you're working on a project involving medium-hard rock. The rounded design of these buttons ensures smoother entry and reduced wear on your equipment. It's like having that perfect pair of shoes that feel just right, no matter how rough the path.

Durability and Wear Resistance

These buttons are truly built to last. One of my colleagues once shared how switching to spherical buttons extended the lifespan of their equipment in a particularly abrasive mining environment. This durability means fewer replacements and more cost savings—something every project manager can appreciate where longevity is crucial2.

Energy Transfer and Efficiency

The efficiency of spherical buttons is no small feat. Their shape optimizes energy transfer when breaking rock, ensuring minimal energy loss. Imagine if every push-up you did converted directly into strength without any wasted effort—that’s the kind of efficiency we’re talking about here.

Adaptability to Different Rock Types

One thing I’ve learned is how crucial adaptability is in the field. Spherical buttons can handle various rock types, from softer formations to medium-hard environments. This flexibility often leads to them being combined with other button shapes in drill bits, creating a powerhouse tool ready to tackle any challenge head-on, optimizing drilling performance3.

Spherical buttons have the longest service life in abrasive conditions.True

Spherical buttons last longer due to their wear resistance in abrasive formations.

Ballistic buttons are best for soft rock formations.False

Ballistic buttons are more effective in medium-hard to hard rock formations.

How Do Ballistic Buttons Enhance Drilling Performance?

Ever wonder how some drilling bits seem to glide through rock like a hot knife through butter? The secret might just lie in their ballistic buttons!

Ballistic buttons enhance drilling performance by significantly increasing penetration rates and ensuring straighter holes, particularly in medium-hard to hard rock formations. Their design optimizes energy transfer and rock fragmentation, making them more efficient than other button types in challenging conditions.

Understanding the Mechanics of Ballistic Buttons

I remember my first encounter with ballistic buttons on a drilling project. It was like magic seeing these little marvels transform a grueling task into something almost seamless. What sets them apart is their higher protrusion compared to spherical buttons. This design delivers focused energy directly to the rock surface, which in turn speeds up penetration and minimizes wear on the drill bit.

Moreover, the design of ballistic buttons contributes to producing straighter holes. This is particularly crucial in applications where precision is paramount, such as in mining or construction projects4. By maintaining hole straightness, ballistic buttons minimize deviations that can lead to operational inefficiencies or increased costs.

Enhanced Rock Fragmentation and Cleaning

The first time I saw ballistic buttons in action, their efficiency in breaking rock was apparent. Their protruded design ensures superior energy transfer, leading to effective rock fragmentation. This not only accelerates drilling but also ensures the debris is cleared efficiently, minimizing downtime and enhancing drilling efficiency5.

Furthermore, because ballistic buttons produce cleaner holes, there's less chance of bit jamming or reduced penetration due to debris buildup. This self-cleaning action is vital in maintaining consistent drilling performance over extended periods.

Applications Across Varied Rock Formations

While ballistic buttons excel in medium-hard to hard rocks, their versatility shines across various geological conditions. They strike a balance between penetration rate and durability, making them ideal for professionals seeking efficient and cost-effective solutions.

In regions with diverse rock formations, using bits equipped with ballistic buttons has noticeably improved operations. The versatility of these buttons allows for optimized performance regardless of the specific challenges posed by the formation type, leading to reduced tool changeovers and enhanced project timelines.

Ballistic buttons produce straighter holes.True

Ballistic buttons have a higher degree of protrusion, enhancing hole straightness.

Spherical buttons offer better impact resistance than parabolic.False

Parabolic buttons are specifically designed for improved impact resistance.

When Should You Use Parabolic Buttons?

Ever wondered why some drilling projects just hit rock bottom while others sail through smoothly? It might just be about choosing the right button shape.

I find that using parabolic buttons is crucial when working with harder rock formations where improved impact resistance and energy transfer are key to efficient drilling.

Understanding the Parabolic Button Design

Let me take you back to a time when I was facing one of the toughest drilling challenges. The rock formations were as stubborn as a mule, and no matter what I tried, nothing seemed to work. That's when I stumbled upon parabolic buttons. Their unique design intrigued me. These buttons are specifically crafted for scenarios where traditional ones can't keep up. The magic lies in their shape, which allows them to endure significant impacts and makes them perfect for drilling into those unyielding, harder rocks.

Key Benefits in Harder Rock Formations

I remember the first time I saw parabolic buttons in action; it was like watching a seasoned chef effortlessly chop through vegetables. They didn't falter or crack under pressure but maintained their form even when facing the toughest materials. This resilience makes them my go-to choice when dealing with abrasive and dense rock conditions. Their design not only improves impact resistance6 but also ensures that all the energy from the drill is effectively transferred to the rock surface, enhancing overall efficiency.

Comparing Parabolic Buttons with Other Shapes

When it comes to drilling, selecting the right button shape can feel like choosing the right tool from a Swiss army knife. While spherical buttons are versatile, and ballistic ones offer speed, parabolic buttons strike the perfect balance by providing superior impact resistance. I've found this particularly crucial when both durability and efficiency are non-negotiable. In my experience, they often outperform other shapes in challenging conditions, making them a justified choice in specific drilling contexts.

Practical Applications and Considerations

Choosing the right button is like matching your tool's strengths with the task at hand. When dealing with abrasive conditions7, parabolic buttons are my trusty sidekick. Before deciding whether to use them, I always consider factors such as the hardness of the rock formation, expected wear patterns, and desired penetration rate. These considerations ensure I'm equipped for optimal performance and not left scrambling halfway through a project.

Spherical buttons have the longest service life.True

Spherical buttons are known for their durability in abrasive conditions.

Ballistic buttons perform better in soft rock formations.False

Ballistic buttons are more effective in medium-hard to hard rock formations.

Why should I consider semi-ballistic buttons for versatile drilling?

When it comes to drilling, the secret sauce often lies in choosing the right tools. And for me, semi-ballistic buttons have been a game-changer, blending efficiency and versatility perfectly.

Semi-ballistic buttons offer the perfect mix of penetration power and durability, ideal for tackling diverse rock formations. Their unique design enhances drilling efficiency and impact resistance, especially in medium to hard rock conditions.

The Balance of Penetration and Durability

Let me take you back to when I first tried semi-ballistic buttons. I was working on a project with challenging rock formations that seemed almost impossible to penetrate efficiently without compromising tool durability. That's when I discovered the engineering genius behind these buttons—they combine the best of both spherical8 and ballistic9 designs. This meant I could achieve impressive penetration rates without constantly replacing worn-out bits, keeping our project running smoothly.

In drilling operations, this translates to less frequent bit replacements and reduced downtime, allowing projects to proceed smoothly.

Versatility Across Rock Types

One of my favorite aspects of semi-ballistic buttons is their adaptability. Imagine working in an area where the rock types change dramatically over short distances. Switching equipment every time wasn't practical, but these buttons proved to be a lifesaver. They handled everything from medium to hard rock formations, reducing our need for constant equipment changes and, in turn, saving us a significant amount of money on large-scale projects.

Their design is suitable for conditions ranging from medium to hard rock formations, making them a versatile option in unpredictable geological environments. This adaptability often means fewer changes in equipment, which can lead to cost savings10 in large-scale drilling operations.

Improved Impact Resistance

In one particular project, we faced abrasive conditions that would have chewed through standard tools. The semi-ballistic buttons' enhanced impact resistance was crucial here. Their ability to withstand harsh conditions ensured a longer service life and consistent performance, which kept our operations efficient and minimized unexpected downtimes.

Semi-ballistic buttons provide enhanced impact resistance compared to their fully ballistic counterparts. This feature is particularly beneficial when working in abrasive conditions where wear and tear are significant concerns.

Energy Transfer Efficiency

I also found that the design of semi-ballistic buttons significantly improves energy transfer to the rock. This balance between energy application and wear not only made drilling more efficient but also kept penetration rates consistent over time.

The design allows for effective energy transfer to the rock, achieving a balance11 between energy application and wear, resulting in optimal rock breaking efficiency and consistent penetration rates over time.

Understanding these mechanics allowed me to make better-informed decisions about equipment choices, which ultimately led to enhanced project outcomes and operational efficiencies.

Ballistic buttons produce straighter holes than spherical ones.True

Ballistic buttons have higher protrusion, resulting in straighter holes.

Flat buttons are best for medium-hard rock formations.False

Flat buttons are used in the hardest rock formations, not medium-hard.

When Are Flat Buttons Most Effective?

Have you ever wondered when those sleek flat buttons on your favorite apps are actually the best choice?

Flat buttons are most effective in minimalistic interfaces where simplicity shines. They thrive on neutral or contrasting backgrounds, delivering a clean look that doesn’t overwhelm. Ideal for secondary actions or maintaining a subtle visual hierarchy, they keep the focus on what really matters without stealing the spotlight.

Understanding the Context of Use

Imagine this: you're scrolling through a news app, and everything feels just right—uncluttered and easy to navigate. That's the magic of flat buttons at work in minimalist designs. They blend in seamlessly, creating an interface that’s all about the content without any distracting visual noise. Personally, I've found them perfect for apps where I want the information to be the star, such as media platforms12.

Visual Hierarchy and User Guidance

Visual hierarchy is like a good story; it leads you effortlessly from one point to the next. Flat buttons are the understated supporting actors in this narrative, taking on roles that aren’t center stage but still essential—like a trustworthy sidekick. When I'm designing, I use them to complement main actions with more prominent button styles, ensuring primary tasks like purchases or form submissions stand out.

Effective Color Usage

Ever notice how a pop of color can change everything? Flat buttons can be that pop on a grayscale background, catching your eye without needing flashy designs. It’s like wearing a bold tie with a classic suit—subtle yet impactful. I often use this trick for call-to-action areas where engagement should be easy yet not overpowering.

Compatibility with Modern Design Trends

If you’re into modern design trends as much as I am, you’ll know that flat buttons are here to stay. Their simple, gradient-free style not only looks sharp but also helps with faster load times and responsiveness. Incorporating them is like adding a timeless piece to your wardrobe—always in vogue.

Scenarios for Flat Button Usage

In scenarios where users know their way around—think productivity tools or dashboards—flat buttons shine. They don’t scream for attention but are there when you need them, like a good friend who doesn’t need constant reassurance. I've seen them work wonders in interfaces where users are focused on data visualization or task management, letting the data itself lead the dance.

To dive deeper into how flat buttons fit into broader UI strategies, check out user experience trends13 and design principles14. These resources have helped me refine my approach to button usage, offering insights that make every click count.

Spherical buttons last longer in abrasive conditions.True

Spherical buttons have a longer service life in abrasive formations.

Flat buttons are ideal for medium-hard rock formations.False

Flat buttons are typically used in the hardest rock formations.

How Do Conical Buttons Perform in Extreme Conditions?

Ever wondered how those conical buttons hold up when the going gets tough? Let me share what I've discovered about their resilience in the harshest conditions.

Conical buttons excel in extreme conditions due to their sharp design, offering superior penetration and wear resistance. Their durability and efficiency make them an excellent choice for challenging drilling applications.

The Design Advantage of Conical Buttons

You know, I’ve always been fascinated by how something as small as a button can make such a big impact, literally! Conical buttons have this sharp point that just slices through hard, abrasive rock like a hot knife through butter. When I first saw it in action on a drilling site, I was amazed at how effortlessly it cut through the stubborn rock. It’s the design that makes all the difference—focusing energy directly onto the rock surface so efficiently.

In extreme conditions, such as those involving high temperatures or highly abrasive materials, conical buttons maintain their integrity and effectiveness. Their ability to withstand significant wear makes them an excellent choice for operations where durability is crucial. Learn more about durability15 in drilling tools.

Performance in High-Temperature Environments

Speaking of heat, there’s this one time we were on a project where the temperatures soared. We were all sweating buckets, but those conical buttons? They didn’t flinch. Their robust construction means they can take the thermal stress in stride. It’s like they were made for it! And the way they dissipate heat is pretty ingenious too, preventing any risk of failure.

When exposed to high temperatures, conical buttons retain their cutting efficiency thanks to their robust construction. High-temperature environments can cause some materials to lose strength or become less effective. However, the material composition of conical buttons is often designed to handle thermal stress, ensuring consistent performance.

Moreover, the design helps in dissipating heat generated during drilling, reducing the risk of button failure due to thermal expansion or fatigue. This attribute makes them suitable for geothermal drilling or other applications where elevated temperatures are a factor. Explore geothermal drilling applications16.

Wear Resistance and Longevity

Now, let’s talk about durability. The material used in these buttons is usually high-grade tungsten carbide, which is known for its toughness. I’ve seen them endure some pretty abrasive environments without a hitch.

The material used for conical buttons typically includes high-grade tungsten carbide, which provides exceptional wear resistance. This characteristic is crucial in extreme conditions where abrasive forces are prevalent.

Furthermore, their self-sharpening nature helps maintain cutting efficiency as they wear down—kind of like how a pencil sharpens itself as you write. This feature is particularly beneficial in abrasive environments where maintaining peak performance is vital for operational efficiency. Investigate the self-sharpening feature17 of different button designs.

Versatility Across Rock Formations

And here’s where they really shine—their versatility across various geological settings without needing frequent tool changes saves us time and money.

Conical buttons are versatile across a range of hard rock formations. Their ability to handle both high-impact and abrasive conditions makes them an ideal choice for mining, construction, and other heavy-duty drilling applications.

This adaptability is particularly beneficial in projects involving mixed rock types or variable conditions where tool switching can lead to downtime and increased costs.Discover more about adaptable drilling tools18.

It’s experiences like these that make me appreciate the engineering behind conical buttons—they’re not just tools; they’re workhorses that keep projects moving forward in some of the toughest conditions out there.

Spherical buttons last longer in abrasive conditions.True

Spherical buttons have a longer service life in abrasive formations.

Ballistic buttons produce straighter holes than spherical ones.True

Ballistic buttons result in straighter holes compared to spherical buttons.

Conclusion

The shape of carbide buttons on DTH drill bits significantly influences drilling efficiency, affecting penetration rates, wear resistance, and performance across various rock formations.

-

Explore how spherical buttons are used across different industries. ↩

-

Learn why durability enhances cost-effectiveness in industrial use. ↩

-

Understand the role of shape in optimizing drilling efficiency. ↩

-

Learn why precise drilling is crucial for construction stability. ↩

-

Discover the mechanics behind enhanced efficiency with ballistic buttons. ↩

-

Learn how impact resistance enhances performance in tough conditions. ↩

-

Understand why parabolic buttons excel in abrasive environments. ↩

-

Explore how spherical buttons offer extended service life. ↩

-

Understand how ballistic buttons achieve higher penetration rates. ↩

-

Learn about potential cost savings with adaptable drilling tools. ↩

-

Discover the importance of energy transfer balance in drilling. ↩

-

Discover how media platforms use minimalistic designs effectively. ↩

-

Learn about the latest user experience trends shaping UI design. ↩

-

Explore key principles that guide effective UI design. ↩

-

Understand why certain tools last longer in harsh conditions. ↩

-

Explore how conical buttons are used in geothermal energy extraction. ↩

-

Learn about maintaining cutting efficiency through self-sharpening. ↩

-

See how versatile tools save time and cost across projects. ↩