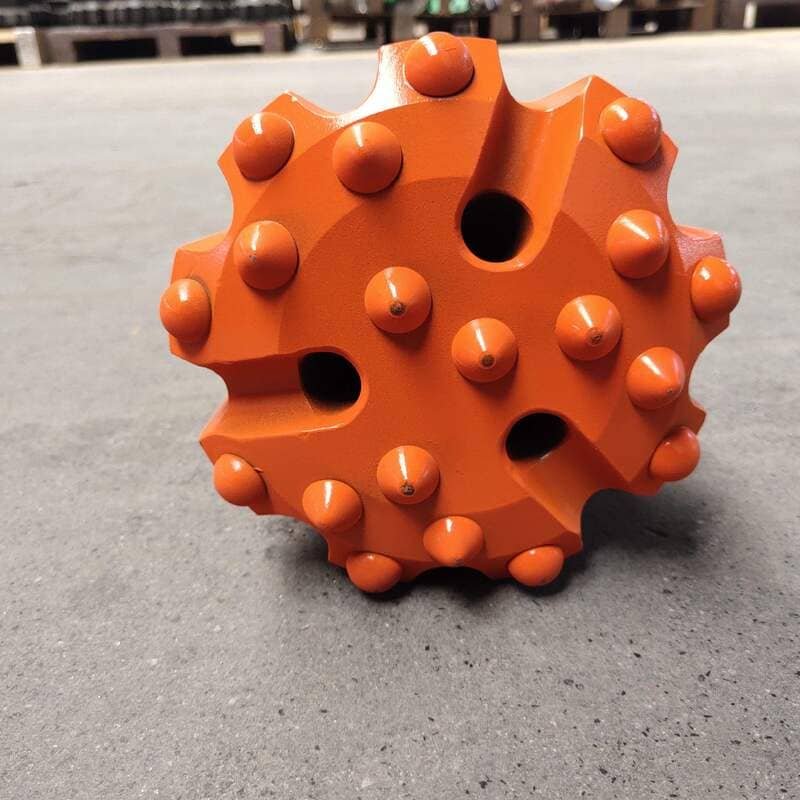

Ever wondered what it really takes to tweak DTH drill bits for top-notch performance? Let me share some insights.

The costs for adding specific functions to DTH drill bits can range from 10-50% more, depending on the enhancements like material upgrades, custom face designs, or special coatings. Each tweak is designed to boost performance and longevity in particular drilling conditions.

Sure, these customizations might hike up the initial investment, but here's the kicker: they pay off big time in the long run. I remember a project where we decided to go for those specialized coatings despite the higher upfront costs. It felt like a leap of faith back then, but once the bits hit those tough rock formations, we realized how much downtime and replacements we actually saved. Each adjustment tailored for specific needs turned into a game-changer for our operations, improving both efficiency and lifespan of our equipment.

Customizing DTH drill bits always increases costs by 10-50%.False

Cost increase varies and may not always be within 10-50% range.

Material upgrades in DTH bits improve durability.True

Upgraded materials enhance resistance to wear, boosting durability.

How Do Material Upgrades Affect DTH Drill Bit Costs?

Material upgrades for DTH drill bits can feel like a significant decision, with each choice impacting your wallet and work efficiency. But what if I told you they could actually save you money in the long run?

Material upgrades in DTH drill bits, like enhanced carbide inserts and special coatings, can increase costs by 10-50%. These improvements boost durability and performance, potentially justifying the higher initial investment through long-term savings.

When I first considered upgrading my DTH drill bits, the price tags were daunting. But I realized the true cost wasn’t just in dollars—it was also in the time and hassle of frequent replacements. Let’s dive into how these upgrades play out.

The Role of Enhanced Carbide Inserts

Imagine upgrading your regular shoes to those high-performance sneakers. Enhanced carbide inserts in DTH drill bits1 are like that, made from premium tungsten carbide or special composites. They don't just promise better wear resistance; they deliver it, often boosting your drilling penetration rates. This can mean a cost bump of 10-30%, but think of it as investing in fewer pit stops.

Custom Face Design's Cost Implications

I once had a drill bit customized to match a specific rock formation, and it was like finding the perfect tool for the job. Custom face designs involve engineering and testing, leading to a 15-25% cost hike. Yet, the payoff comes when you see how seamlessly it cuts through the formation, saving you headaches down the line.

Specialized Flushing Holes for Enhanced Air Flow

Improved airflow through specialized flushing holes might seem minor, but imagine clearing debris as effortlessly as a leaf blower handles a driveway. For certain conditions, this can add 5-15% to costs but pays off by preventing frustrating clogs.

Reinforced Bit Bodies for Increased Durability

Think of reinforced bit bodies like putting your drill bits on a fitness plan—they become tougher and last longer. Upgrading to strengthened steel or adding reinforcements increases durability, crucial in abrasive formations, at a 10-20% price increase.

Impact of Protective Coatings on Costs

Applying protective coatings, whether diamond-enhanced or titanium layers, is akin to giving your bits an armor. It might seem pricey at 20-50%, but the extended lifespan means fewer replacements and smoother operations over time.

Custom Thread Designs and Their Financial Impact

Finally, adapting thread designs for specific rigs can feel like finding a glove that fits just right. This customization usually adds 5-10% to the overall drill bit cost2, ensuring stability and compatibility.

| Material Upgrade | Cost Increase | Benefit |

|---|---|---|

| Enhanced Carbide Inserts | 10-30% | Improved wear resistance and penetration capabilities |

| Custom Face Design | 15-25% | Optimized performance for specific formations |

| Specialized Flushing Holes | 5-15% | Enhanced debris removal and prevention of clogging |

| Reinforced Bit Bodies | 10-20% | Increased durability in challenging conditions |

| Protective Coatings | 20-50% | Extended lifespan through superior abrasion resistance |

| Custom Thread Designs | 5-10% | Ensured compatibility and enhanced attachment stability |

In the end, while material upgrades on DTH drill bits might initially seem costly, they often bring valuable returns in performance and longevity. It's a balance between upfront costs and ongoing savings that I've found really rewarding.

Enhanced carbide inserts increase DTH drill bit costs by 10-30%.True

Upgraded carbide inserts enhance wear resistance, raising costs by 10-30%.

Custom thread designs reduce overall DTH drill bit costs.False

Custom thread designs typically add 5-10% to the drill bit cost.

How Does Customizing Face Designs Affect Product Pricing?

Ever wondered how changing the face of a product could change its price?

Face design customization impacts pricing by altering production costs. Adjustments in material, complexity, and testing can lead to a 10-50% increase in prices, each change enhancing performance for specific applications.

Material Considerations in Face Design

When I first dipped my toes into the world of face design customization, I quickly realized just how pivotal material choices were. Imagine this: you're choosing between standard materials and premium tungsten carbide3 inserts. The latter might significantly boost durability and penetration, but it can also spike costs by 10-30%. It's like deciding whether to splurge on those high-end sneakers—sure, they last longer, but your wallet feels the burn.

Design Complexity and Engineering

Delving into design intricacies can feel like solving a complex puzzle. When working on custom face profiles—think concave or convex designs—the engineering challenge ramps up. I recall the meticulous R&D efforts4 involved, which can bump up prices by 15-25%. Each design is like a tailored suit, crafted precisely for specific geological conditions, aiming to optimize drilling efficiency.

Testing and Validation

Testing these custom designs is akin to preparing for a big exam. Comprehensive testing ensures that the designs meet performance expectations, adding to the overall cost. I've seen teams conduct thorough comprehensive analysis5, including simulations and field trials, to validate the effectiveness across various environments.

Example of Cost Variation

| Customization Aspect | Typical Cost Increase (%) |

|---|---|

| Material Upgrades | 10-30% |

| Complex Design Engineering | 15-25% |

| Extensive Testing | 5-10% |

Market Demand and Customization

The push for custom face designs often mirrors market needs for specialized equipment. Industries like mining and construction frequently demand these customizations to tackle unique challenges. This dynamic shapes both pricing strategies and product availability.

Navigating these factors helps businesses make informed decisions on whether investing in face design customization aligns with their operational needs and budget. It's a bit like weighing the pros and cons of upgrading your trusty old car—worth it if it fits your goals and doesn't break the bank.

Premium materials increase costs by 10-30%.True

Using high-quality materials like tungsten carbide raises costs due to durability benefits.

Complex designs can decrease costs by 15-25%.False

Intricate designs require more R&D, increasing costs rather than decreasing them.

Why Is Enhanced Air Flow Design Important for Drill Bits?

Imagine drilling into a rock with ease, thanks to the breeze of innovation blowing through your drill bit.

Enhanced airflow design in drill bits is vital for effective debris removal, cooling, and pressure management, leading to faster drilling speeds, less wear, and superior performance in various geological settings.

Improving Debris Removal

I remember the first time I saw a drill bit clog mid-operation. It was like trying to drink a milkshake through a straw that suddenly had a cookie in it—frustrating and inefficient. Enhanced airflow design has been a game-changer for this. It sweeps away the debris as you drill, ensuring a clear path and smoother operation. Imagine having a constant gust of wind clearing your way while you work.

-

Standard vs. Enhanced Airflow

Feature Standard Airflow Enhanced Airflow Debris Clearance Moderate High

Cooling and Pressure Management

The heat from drilling can be intense—I’ve felt it radiating off the equipment during long jobs. Enhanced airflow acts like your personal air conditioner for the bit, dissipating heat and preventing overheating. It’s like being on a road trip with a working AC; everything runs smoother and lasts longer.

Moreover, managing internal pressure is vital in maintaining the bit's performance. Consistent airflow keeps internal pressures steady, adapting to different depths and rock types. It's like having an autopilot that adjusts to turbulence without you having to lift a finger.

Adapting to Geological Conditions

Every drilling site is like a mystery novel—filled with unexpected twists. I’ve faced many geological surprises, from hard rock fortresses to loose sediment mazes. Enhanced airflow design allows customization to meet these challenges head-on, much like choosing the right playlist for the journey ahead.

-

Geological Adaptations

Geological Type Standard Design Limitations Enhanced Design Solutions

This adaptability is crucial for companies like Eazydrill that operate globally across diverse industrial sectors. It allows them to provide solutions that meet unique project demands efficiently, enhancing their competitive edge in the market.

Enhanced airflow increases drilling speed.True

Enhanced airflow clears debris effectively, reducing resistance and increasing speed.

Standard airflow provides better cooling than enhanced.False

Enhanced airflow improves cooling by efficiently dissipating heat from the drill bit.

What Makes Reinforced Bit Bodies Stand Out?

Ever tried drilling through concrete and felt like you were hitting a brick wall? That's where reinforced bit bodies come in handy. Let's dive into why they're the unsung heroes of tough drilling jobs.

Reinforced bit bodies excel in durability and efficiency, thanks to their robust materials and smart engineering. They're built to tackle abrasive environments, offering longer life, greater efficiency, and making them essential for drilling through hard rock and concrete.

Enhanced Durability and Lifespan

Imagine being halfway through a big project, and your drill bit just gives up. That's why I turned to reinforced bit bodies, which are made from high-grade steel or composites. These bits shrug off wear and tear, meaning fewer replacements and less downtime6.

Improved Drilling Efficiency

The first time I used a reinforced bit, I noticed how effortlessly it sliced through concrete. It’s all in the design—optimized cutting angles and special coatings cut down on friction and heat. This means faster drilling and saves me time7 and money.

| Feature | Benefit |

|---|---|

| High-Grade Materials | Increased resistance to wear; suitable for abrasive environments |

| Optimized Design | Faster penetration; reduced friction and heat generation |

| Specialized Coatings | Extended lifespan; enhanced performance in challenging conditions |

Suitability for Challenging Conditions

I remember a project where regular bits just couldn't cut it—literally. Reinforced bit bodies, however, thrived under pressure. Whether it's mining8, construction, or oil and gas, these bits handle extreme conditions without a hitch.

Cost Efficiency in the Long Run

Sure, they might be a bit pricier upfront, but think of them as an investment. Fewer replacements mean less hassle and more savings in the long haul. For long-term projects or harsh conditions9, they're worth every penny.

Reinforced bits reduce operational downtime.True

Their durability means fewer replacements and repairs, minimizing downtime.

Reinforced bits are less efficient in tough conditions.False

They are designed for efficiency in challenging environments, reducing friction.

How Do Special Coatings Extend the Life of Drill Bits?

Have you ever felt the frustration of drill bits wearing out too quickly, mid-project? I have, and discovering special coatings was a game-changer.

Special coatings, like Titanium Nitride (TiN) and Diamond-Like Carbon (DLC), significantly enhance drill bits by boosting wear resistance, reducing friction, and preventing overheating. These benefits extend the lifespan and efficiency of drill bits, making them a cost-effective choice for frequent users like myself.

I remember one time when I was knee-deep in a home renovation project, only to have my drill bit give up on me halfway through. That's when I stumbled upon the concept of special coatings. These coatings aren't just about adding a layer of protection; they're about transforming how long your tools last and how well they perform.

Types of Special Coatings and Their Benefits

Special coatings are engineered to address specific challenges faced during drilling. Here's a look at some common coatings and their benefits:

| Coating Type | Benefits |

|---|---|

| Titanium Nitride (TiN) | Increases hardness, reduces friction |

| Diamond-Like Carbon (DLC) | High wear resistance, prevents overheating |

| Ceramic Coatings | Withstands high temperatures, enhances durability |

Titanium Nitride (TiN)

My favorite for its golden hue, TiN is like the knight in shining armor for drill bits. It boosts surface hardness and slashes friction, which means I can drill faster and longer without worrying about wear and tear. Learn more about TiN's benefits10.

Diamond-Like Carbon (DLC)

When tackling tough materials, DLC coatings are the heroes. They offer superior wear resistance and thermal management, keeping the bit sharp and efficient even after prolonged use.

Application Process and Considerations

The process of applying these coatings is fascinating—think Physical Vapor Deposition (PVD), where the coating material is vaporized and deposited onto the drill bit. It's like giving your tools a superhero upgrade! But remember, the base material needs to match well with the coating for optimal results.

Factors Affecting Coating Effectiveness

From my experience, several factors can affect how well these coatings work:

- Material Composition: Ensuring the drill bit material is compatible with the coating is crucial.

- Operating Conditions: High heat or abrasive conditions might challenge even the toughest coatings.

- Maintenance Practices: Regular cleaning and maintenance can make a world of difference.

Want to dive deeper into how these coatings are applied and their impact? Check out advanced coating technologies11. Knowing all this has helped me save time and money on projects, and I hope it does the same for you!

Titanium Nitride coatings increase drill bit hardness.True

TiN coatings increase surface hardness, reducing friction and wear.

Ceramic coatings are ineffective at high temperatures.False

Ceramic coatings withstand high temperatures, enhancing durability.

Is investing in custom thread design a smart choice?

Imagine enhancing your product's performance and reliability with just a tweak in its design. Custom thread design offers precisely that, but is it worth the extra bucks?

Custom thread design is often worth the additional expense as it tailors products to specific needs, enhances durability, and improves performance. This investment is justified, especially in high-reliability industries demanding precision.

Diving into Customization Value

I remember the first time I debated whether to invest in custom thread designs for my products. At first, the idea seemed extravagant. But when I dug deeper, especially for my clients in the drilling equipment manufacturing12 sector, the benefits became crystal clear. Those unique thread patterns improved attachment stability and significantly reduced operational risks.

What Drives Custom Thread Costs?

Now, let's talk dollars and sense. Investing in custom threads isn't just about a fancy design. It involves design development, material upgrades, and rigorous testing. I found that adapting a thread pattern to fit a specific rig could add about 5-10% to the cost. But, wow! The payoff in terms of longer-lasting tools and reduced downtime was worth every penny.

| Customization Aspect | Cost Increase |

|---|---|

| Material Upgrades | 10-30% |

| Bit Face Design Customization | 15-25% |

| Enhanced Air Flow Design | 5-15% |

| Reinforced Bit Bodies | 10-20% |

| Special Coatings | 20-50% |

Industry-Specific Perks

In drilling, for instance, custom threads can significantly boost performance. I recall a client who tailored their threads to specific geological conditions and saw a noticeable increase in drilling speed and efficiency. Not to mention, the premium materials used in custom designs led to products that lasted much longer, cutting down on unexpected repair costs.

Decision-Making: Weighing Benefits vs. Costs

When I weigh custom thread options, it's all about balancing performance improvements against costs. You have to consider factors like geological conditions13, equipment compatibility, and project scope to determine if customization is a go.

And don’t forget about choosing the right partner. I always emphasize the importance of working with suppliers who excel in R&D. It's their expertise that ensures the custom threads meet industry standards and project needs—leading to better outcomes and aligning with strategic business goals.

Aligning Customization with Business Goals

Ultimately, any decision to invest in custom thread design should align with broader business objectives—whether that's reducing downtime, improving product lifespan, or hitting specific project milestones. By syncing these goals with your customization strategy, you can ensure you're getting tangible returns on your investment.

Custom threads improve drilling efficiency.True

Tailored threads enhance performance by adapting to geological conditions.

Custom thread design costs increase by 50%.False

The cost increase varies, with most aspects adding 5-30%.

Conclusion

Customizing DTH drill bits can increase costs by 10-50%, but enhancements like material upgrades and special coatings improve performance, durability, and long-term savings in drilling operations.

-

Explore how premium tungsten carbide inserts enhance drill bit performance and durability, affecting cost efficiency. ↩

-

Discover the importance of custom thread designs in ensuring stability and compatibility with drilling rigs. ↩

-

Learn how tungsten carbide enhances drill bit durability and performance, which justifies its cost. ↩

-

Explore how research and development efforts contribute to customization costs. ↩

-

Understand the importance of rigorous testing in ensuring custom designs meet performance standards. ↩

-

Understanding downtime's impact on operations highlights the importance of durable equipment, helping readers appreciate reinforced bits' value. ↩

-

Explore how efficient drilling translates to financial benefits, reinforcing the economic advantage of reinforced bit bodies. ↩

-

Mining industry insights illustrate the demanding environments where reinforced bits excel, emphasizing their necessity. ↩

-

Learn about the challenges in construction that necessitate robust equipment like reinforced bit bodies. ↩

-

Discover how TiN coating increases hardness and reduces friction, enhancing drill bit longevity. ↩

-

Learn about innovative methods in coating applications that improve durability and performance. ↩

-

Explore how unique thread patterns enhance equipment stability and reduce operational risks. ↩

-

Understand geological factors influencing thread customization and its benefits. ↩