I still remember my first encounter with Mincon's DTH drill bits—an unexpected game-changer in my drilling projects.

Mincon's DTH drill bits are celebrated for their remarkable performance and robustness in tough environments, thanks to their cutting-edge designs and technological innovations. These qualities ensure maximum drilling efficiency and dependability across a variety of uses.

Every time I think about those early days using Mincon's bits, I'm reminded of how their clever design elements truly made the difference. It's more than just having the right tools—it's about the peace of mind that comes from knowing each component has been crafted with precision and purpose. From their thoughtful face designs to the efficient air delivery system, Mincon’s innovations have consistently delivered results, whether we're battling rocky terrain or navigating underwater challenges. It’s no wonder these bits have become a staple in our arsenal, providing not just reliability but also a sense of partnership with the technology that drives our success.

Mincon's DTH drill bits are known for superior performance.True

Mincon's DTH drill bits are celebrated for their high efficiency and reliability.

Mincon's DTH drill bits lack durability in tough conditions.False

They are renowned for durability, performing well in challenging environments.

How Do Mincon's Drill Bits Perform in Challenging Environments?

When I first encountered Mincon's drill bits, I was skeptical. Could they really stand up to the harsh environments I often deal with?

Mincon's drill bits are engineered to thrive in tough environments, thanks to their cutting-edge designs and high-quality materials. These attributes ensure durable, consistent performance, making them a top choice for challenging drilling tasks.

Superior Performance and Durability

Reflecting on my experience, I remember a project deep in the Rockies. The terrain was unforgiving, with rock-hard surfaces that chewed through lesser equipment. But Mincon's drill bits didn't flinch. They boast durability from advanced materials1 that extend their lifespan, allowing me to focus more on the work and less on equipment failures.

Innovative Design Features

I was once drilling near a water-rich site and worried about efficiency loss. Mincon’s varied designs, like their convex and concave faces, came through brilliantly. They adapt seamlessly to different conditions, whether it's abrasive rock formations2 or aquatic environments. Their air delivery system is like having a trusty partner that ensures peak performance regardless of the challenge.

Technological Advancements

Mincon's commitment to innovation is evident in their technology. During a particularly grueling project, the improved penetration rates and efficiency of their bits saved us time and money. Their proprietary technologies focus on maximizing rock-breaking3 capabilities, a feature I learned to appreciate when budgets were tight and every minute counted.

Compatibility and Versatility

One thing that impresses me about Mincon is how their drill bits integrate smoothly with various systems. Whether I'm using their renowned DTH hammers4 or another system, these bits are versatile and adaptable across multiple projects, providing a kind of equipment harmony that makes the job so much easier.

Global Support and Accessibility

It's comforting to know that wherever my projects take me, Mincon’s global support network is there. Their extensive distribution channels mean I can count on getting expert advice and products anywhere in the world. This kind of support has been invaluable in optimizing my drilling operations.

| Feature | Benefit |

|---|---|

| Advanced Materials | Enhanced durability and longevity |

| Multiple Face Designs | Optimized performance for different terrains |

| Efficient Air Delivery | Ideal for water-rich drilling environments |

| Global Support Network | Comprehensive assistance and accessibility |

Understanding these features has helped me—and can help you—appreciate how Mincon's solutions address various challenges in difficult environments.

Mincon drill bits use advanced materials for durability.True

Advanced materials enhance the longevity and durability of Mincon's drill bits.

Mincon's designs are unsuitable for abrasive rock formations.False

Mincon offers designs specifically tailored to handle abrasive rock formations.

What Makes Mincon's Drill Bits Unique?

Remember the last time you marveled at a piece of technology that just seemed smarter than the rest? That's the vibe I get from Mincon's drill bits.

Mincon's drill bits are distinct due to their innovative design, exceptional durability, and versatility across drilling systems. These attributes guarantee top-notch performance, even in tough conditions, making them a go-to choice for experts.

Innovative Design Features

I remember my first encounter with Mincon's drill bits like it was yesterday. It was during a project in the rugged terrains of northern Canada. I was amazed at how their design accommodated every challenge we faced. They offer three distinct face designs—convex for hard rock, flat for softer terrains, and concave for mixed conditions. This adaptability5 is like having a Swiss Army knife for drilling—no matter where the project takes us, there's a Mincon bit ready to tackle it.

| Design Type | Applications |

|---|---|

| Convex | Hard rock |

| Flat | Soft rock |

| Concave | Mixed terrains |

Advanced Material Technology

In one of my earlier projects, we had to drill through incredibly dense basalt. I remember thinking our equipment wouldn't make it through the day. But Mincon's bits proved me wrong—they’re built with cutting-edge materials and technologies that boost both their longevity6 and effectiveness. It's like they have this superpower to slice through the toughest rocks, making our work not just possible, but efficient.

Superior Air Delivery System

When you're working in water-rich environments, maintaining performance is crucial. There was this one time in Australia; the site was just soaked through. Yet, thanks to Mincon's innovative air delivery system, the debris was cleared efficiently, and the bits stayed cool. It was as if they were tailor-made for those wet conditions7.

Compatibility and Versatility

During a hectic drilling season, the last thing I want is to juggle incompatible gear. Mincon’s bits integrate seamlessly with their other solutions like DTH hammers. This compatibility8 makes logistics and inventory so much simpler—one less thing to worry about on already demanding projects.

Global Support Network

Imagine having a team that's got your back wherever you are. That’s what Mincon’s global support feels like. Once, while on a project in a remote area of Chile, we needed some technical advice urgently. Their network ensured we got the help we needed right when we needed it.

By focusing on these key innovations, Mincon's drill bits aren't just tools—they're indispensable partners in conquering some of the most challenging drilling scenarios we face.

Mincon drill bits use three face designs for adaptability.True

Mincon offers convex, flat, and concave designs for different conditions.

Mincon drill bits lack advanced material technology.False

Mincon integrates proprietary technologies for durability and efficiency.

Why Is Compatibility Important for Mincon's Drill Bits?

Compatibility with Mincon's drill bits isn't just about fitting pieces together; it's about ensuring every drill day is smooth and productive, making your equipment work as hard as you do.

Mincon's drill bits are designed for compatibility to boost performance by integrating smoothly with various drilling systems, minimizing downtime, and maximizing efficiency. This adaptability helps tackle diverse geological conditions effectively.

Enhancing Equipment Integration

There was a time when I learned the hard way just how crucial compatibility is. Picture this: I've just invested in new equipment, and excitement is high, but as the day drags on, I find myself tangled in a mess of incompatible parts. That's where Mincon steps in, offering drill bits engineered for seamless integration. For someone like me—maybe you too—who manages equipment inventories across different applications, it's a game-changer. These bits fit in perfectly, slashing downtime and fine-tuning operations.

Mincon's drill bits are engineered for compatibility, meaning they can easily integrate with different drilling systems. This is especially beneficial for distributors like Gary9, who manage equipment inventories across diverse applications. Seamless integration reduces downtime and optimizes operation.

Adapting to Varied Geological Conditions

I once faced a project that seemed impossible due to unpredictable geological conditions. But having the right tools made all the difference. With Mincon, you get bits that are adaptable to multiple face designs—convex, flat, and concave. This flexibility lets me choose the perfect bit for each unique situation, ensuring efficiency and effectiveness no matter what Mother Earth throws my way.

Drill bit compatibility is essential when dealing with varied geological conditions. Mincon offers bits compatible with multiple face designs—convex, flat, and concave. This adaptability allows users to select the most suitable bit for specific ground conditions, ensuring efficiency and effectiveness10.

| Face Design | Optimized For |

|---|---|

| Convex | Hard rock conditions |

| Flat | Soft to medium formations |

| Concave | All-round performance |

Ensuring Durability and Performance

There's nothing more frustrating than equipment that can't keep up. Mincon's dedication to compatibility means their bits pair perfectly with DTH hammers, extending their lifespan and reducing wear—vital for long-term projects in harsh conditions. This ensures that high performance isn't just a promise but a guarantee.

Compatibility also ensures durability. Mincon's bits are designed to work with their DTH hammers, enhancing life span and reducing wear. This aspect is critical in projects requiring long-term usage under harsh conditions, helping maintain high performance11 standards.

Meeting Industry Standards

In my experience, aligning with industry standards isn't just about compliance—it's about peace of mind. Mincon's commitment to compatibility and ISO compliance means their bits fit seamlessly into international operations, eliminating the headache of compatibility issues. Their attention to quality and reliability shines through every project I undertake.

Mincon's dedication to compatibility aligns with industry standards, facilitating ease of maintenance and part replacement. This focus ensures that their bits can be used globally, supporting international12 operations without compatibility issues. Their ISO compliance further underscores their commitment to quality and reliability.

Mincon drill bits integrate with all drilling systems.False

They are compatible with many, but not necessarily all, systems.

Compatibility ensures Mincon bits' durability and performance.True

Designed for DTH hammers, enhancing lifespan and reducing wear.

How Does Mincon Support Its Global Customer Base?

Ever wondered how a company like Mincon manages to keep its global customer base so satisfied?

Mincon supports its global customers by offering innovative product designs, expansive distribution networks, and dedicated technical support, ensuring consistent performance and satisfaction across industries.

Innovative Product Design

I remember the first time I encountered Mincon's drilling solutions. I was awestruck by their diverse range of drill bits and hammers, each tailored for specific geological conditions. It's not just about selling equipment; it's about providing tools that adapt and endure in tough environments, which makes all the difference in the field.

| Product Type | Key Feature | Benefit |

|---|---|---|

| DTH Drill Bits | Convex, flat, and concave face designs | Enhanced penetration rates |

| Reverse Circulation | Accurate sample collection | Reduced contamination |

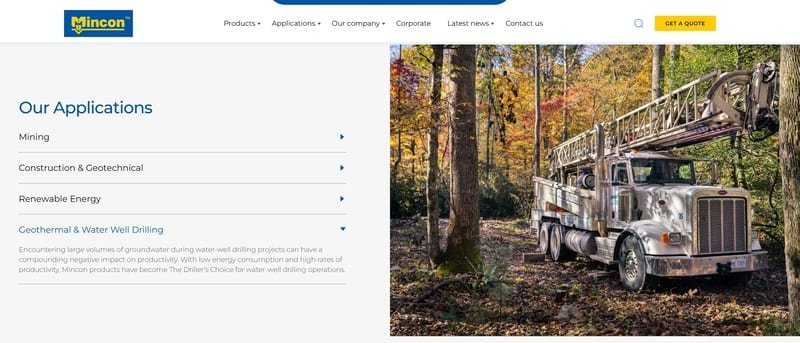

| Water Well Drilling | Efficient in large volumes of water | Consistent performance in wet conditions |

Extensive Distribution Networks

Mincon's global reach reminds me of my own experiences navigating complex distribution channels. Their partnership with local distributors ensures that products are available whenever and wherever needed, minimizing lead times13 and keeping operations smooth—a necessity when you're racing against project deadlines.

Dedicated Technical Support

Having dealt with technical hiccups myself, I can attest to the importance of robust support. Mincon's 24/7 technical assistance is a lifeline, much like having a knowledgeable friend ready to help troubleshoot and optimize your equipment. Their regular seminars and webinars also equip users with the know-how to tackle challenges proactively.

- Support Features:

- 24/7 technical assistance

- Access to training materials and manuals

- Regular technical seminars and webinars

Global Accessibility and Local Expertise

Mincon's blend of global accessibility with local expertise is akin to having the best of both worlds. With regional support centers, they offer swift responses and tailored solutions that cater to local market needs14. It's like having a guide who knows every shortcut in your city.

In conclusion, Mincon's holistic approach—combining cutting-edge design, strategic distribution, and unwavering support—ensures they meet the needs of their global clientele without compromising quality or service standards.

Mincon offers 24/7 technical assistance to clients.True

Mincon provides round-the-clock technical support to help customers.

Mincon's distribution network is limited to Europe and Asia.False

Mincon has a global distribution network, not limited to Europe and Asia.

What are the perks of Mincon's technological advancements?

When it comes to drilling, Mincon's cutting-edge tech investments are truly game-changers. Let me take you through why these advancements are a big deal for anyone in the industry.

Mincon's technological innovations deliver exceptional drilling performance and durability. Leveraging advanced materials and smart designs, they boost penetration rates and ensure broad compatibility across diverse drilling systems.

Superior Performance and Durability

I remember the first time I saw Mincon's drill bits in action; they were like nothing I had seen before. Their resilience in harsh environments is remarkable, making them a staple in any demanding project. This reliability is crucial, especially when you're working under challenging conditions.

Mincon's commitment to technology leads to drilling bits with exceptional performance15 and durability. Their products are engineered to withstand harsh environments, making them a top choice for demanding projects. This ensures reliability even under challenging conditions.

| Feature | Benefit |

|---|---|

| Advanced Materials | Enhanced wear resistance and longevity |

| Innovative Designs | Consistent performance in tough terrains |

Innovative Design

Mincon’s innovative designs are what set them apart. Picture this: their drill bits come with multiple face options—convex, flat, and concave—each tailored for specific tasks. This versatility means I can choose the perfect bit for my unique project needs, knowing it will perform exceptionally well.

Mincon's drill bits boast innovative16 designs with multiple face options like convex, flat, and concave. Each design is optimized for specific drilling applications, enhancing the versatility of their products. This allows users to select the most suitable bit for their unique project needs.

Technological Innovation

Every time I think about their continuous investment in research, I get excited about the possibilities. Mincon's use of cutting-edge materials and proprietary technologies doesn’t just sound impressive—it translates to real-world benefits like improved durability and efficiency. Maximizing penetration rates and rock-breaking efficiency becomes crucial for cost-effective drilling.

Continuous investment in research enhances Mincon's product efficiency. Their use of cutting-edge materials and proprietary technologies improves both durability17 and performance. Such innovations focus on maximizing penetration rates and rock-breaking efficiency, which are crucial for cost-effective drilling.

Compatibility and Versatility

One of the things I appreciate most about Mincon is their focus on compatibility. Whether it’s their DTH hammers or other solutions, everything works seamlessly together. This ensures optimal performance across various applications, making the integration process smooth.

Mincon ensures compatibility across its range of drilling solutions, including class-leading DTH hammers. This compatibility18 guarantees optimal performance across various applications, offering users a seamless integration experience.

Global Support and Accessibility

Having a reliable support system is non-negotiable for me, and Mincon doesn’t disappoint. Their global network means I have access to extensive support and technical assistance no matter where my projects take me. This kind of accessibility reinforces my confidence in choosing Mincon's solutions time and again.

With a robust global network, Mincon provides extensive support19 to clients worldwide. Their responsive customer service and technical assistance ensure efficient drilling operations anywhere, anytime.

Mincon's drill bits are designed for all terrains.True

Mincon uses innovative designs to ensure drill bits perform in various terrains.

Mincon products lack global support and accessibility.False

Mincon provides extensive global support, ensuring efficient operations worldwide.

Conclusion

Mincon's DTH drill bits are renowned for their durability, innovative designs, and superior performance in challenging environments, making them a top choice for diverse drilling applications worldwide.

-

Learn about the materials that enhance the durability of Mincon's drill bits. ↩

-

Discover how specific face designs tackle tough geological conditions. ↩

-

Explore the innovations behind Mincon's efficient drilling tools. ↩

-

Understand how DTH hammers integrate with drill bits for enhanced performance. ↩

-

Understanding the specific applications of different face designs can enhance your selection process for various geological conditions. ↩

-

Discover how advanced materials contribute to the durability and efficiency of drill bits, ensuring longer lifespans and reduced costs. ↩

-

Explore how an efficient air delivery system can improve drilling performance, particularly in water-rich environments. ↩

-

Learn about the importance of compatibility between drill bits and hammers to optimize drilling performance and simplify operations. ↩

-

Discover how Mincon's compatibility features benefit equipment distributors like seamless integration and reduced downtime. ↩

-

Explore how Mincon's drill bits adapt to varied geological conditions with their versatile face designs. ↩

-

Learn about the enhanced performance and durability of Mincon drill bits when used with their DTH hammers. ↩

-

Understand how Mincon's commitment to compatibility meets global industry standards and supports international operations. ↩

-

Learn about Mincon's extensive distribution network and how it enhances product availability globally. ↩

-

Understand how Mincon tailors its solutions to meet local market demands effectively. ↩

-

Explore how advanced materials enhance the durability and performance of drilling bits, providing insights into material choices that improve longevity. ↩

-

Understand how innovative drill bit designs improve drilling efficiency and adaptability to various geological conditions. ↩

-

Discover the role of technology in advancing the durability and efficiency of modern drilling equipment. ↩

-

Learn about the importance of compatibility between DTH hammers and drill bits for optimal performance. ↩

-

Explore how global support networks facilitate efficient operations and client satisfaction in the drilling industry. ↩