I remember the first time I faced the challenge of drilling through fractured rocks—it felt like wrestling with an unpredictable beast.

Fractured rock formations chip DTH drill bits by causing irregular stress distributions and abrupt changes in drilling conditions, increasing impact forces on carbide buttons and edges.

The unpredictability of these formations can be daunting. Imagine trying to navigate a vehicle through a rocky, uneven path; that's what drilling through these rocks feels like. The sudden jolts and shifts can be hard on equipment. By understanding how these geological puzzles impact your drill bits, you can better strategize your approach—choosing the right tools and methods to reduce downtime and save on replacement costs. Let’s explore how these fractured formations impact drill bit performance.

Fractured rocks increase chipping in DTH drill bits.True

Irregular stress and sudden changes in drilling conditions cause increased impact forces.

DTH drill bits last longer in fractured rock formations.False

Fractured rocks cause more wear and tear, reducing bit lifespan.

How does irregular stress distribution affect drill bit durability?

Ever wondered why your drill bits seem to wear out way too fast?

Irregular stress distribution causes drill bits to wear unevenly and chip, especially when navigating fractured rock formations. This uneven resistance leads to concentrated forces that exceed the drill bit's material strength, accelerating wear and tear.

Uneven Wear and Chipping

I remember the first time I realized my drill bits were wearing unevenly—it was during a particularly challenging project where the rocks seemed to fight back at every turn. The bits would encounter varying resistances, and I could practically hear them struggling against the fractured rock formations1. It felt like certain parts of the bit were bearing all the brunt, wearing out faster than others.

| Factor | Impact on Durability |

|---|---|

| Variable Resistance | Increased wear on specific areas of the bit |

| Concentrated Forces | Risk of chipping or cracking |

Impact of Sudden Resistance Changes

Switching between intact and fractured zones was like going from a smooth highway to a bumpy dirt road. The sudden jolts would stress out the carbide buttons on my drill bits, leading to material fatigue2 faster than I could say "replacement." It was frustrating, knowing that each jolt was another step towards a cracked or chipped bit.

- Localized Impacts: Such impacts may cause cracks or fractures in the bit.

- Increased Pressure: High pressure can lead to faster deterioration.

Torsional and Lateral Stresses

Navigating through uneven rock surfaces was akin to walking on a twisted path blindfolded—everything felt misaligned. These torsional and lateral stresses twisted my drill bits against their natural motion, increasing the chances of chipping.

Consider torsional forces3 that twist the drill bit against its normal motion, leading to:

- Misalignment

- Increased abrasion

Abrasive Interactions with Rock Surfaces

Then there were those sharp edges of fractured rocks that acted like sandpaper, grinding down my drill bits at an alarming rate. Keeping up with regular inspections became crucial to prevent premature failures.

- Inspection Frequency: Regular checks can prevent premature failure.

- Maintenance: Routine sharpening or replacement of worn components is recommended.

Vibration and Resonance Effects

Drilling through inconsistent materials was like trying to dance on a vibrating platform—stability was hard to maintain. These vibrations led to oscillations that exacerbated wear, making vibration dampening techniques not just helpful but essential.

- Harmonic Resonance: Certain frequencies can exacerbate these effects, increasing wear.

- Stability Measures: Using vibration dampening techniques can mitigate these risks.

Understanding these factors has been crucial for me in selecting the right tools and techniques for different geological conditions. It not only ensures efficient drilling operations but also prolongs the life of my tools, saving both time and money in the long run.

Uneven wear increases drill bit chipping risk.True

Uneven wear leads to concentrated forces, causing chipping.

Torsional stress reduces drill bit durability.True

Torsional stresses twist the bit, increasing wear and misalignment.

Why Are Carbide Buttons Particularly Vulnerable in Fractured Rocks?

Ever wondered why carbide buttons seem to crumble under the pressure of fractured rocks? It’s not just bad luck. Let’s dive into the hidden challenges these tiny but mighty tools face and how it impacts our drilling adventures.

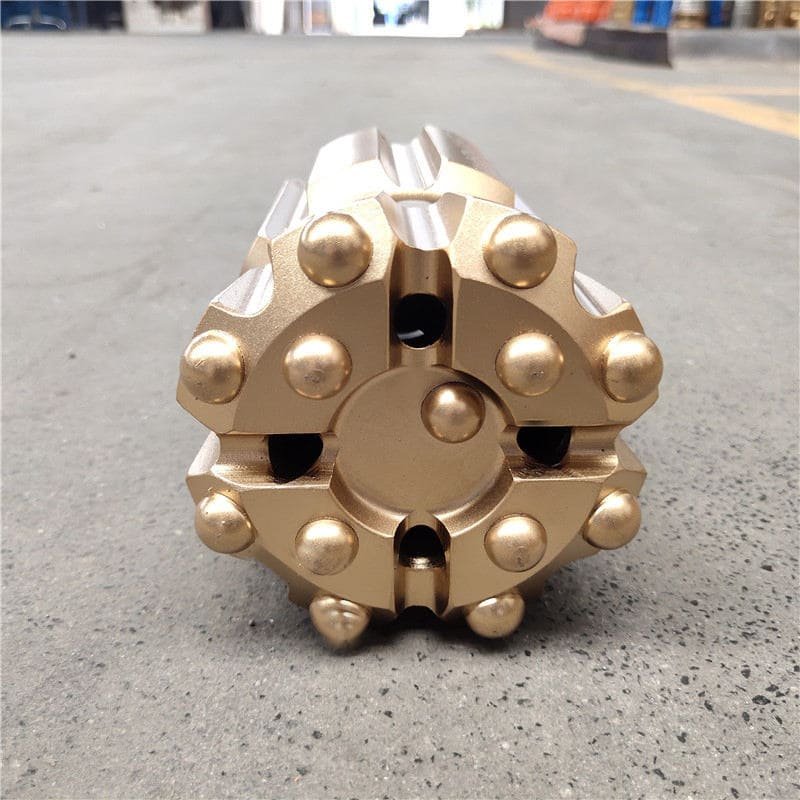

Carbide buttons are vulnerable in fractured rocks due to uneven stress distribution, concentrated impact forces, and increased abrasion. These factors can lead to chipping, fracturing, and reduced tool life during drilling.

Uneven Stress Distribution

Imagine navigating a rocky road where every bump sends a jolt up your spine. That's how carbide buttons feel in fractured rocks. The uneven force distribution they endure as they tackle varying material densities and fracture lines is like constantly shifting sand beneath your feet. As I’ve seen firsthand, this variability in pressure can quickly wear down even the toughest tools, increasing the risk of wear due to variable pressure4.

Concentrated Impact Forces

Picture this: you're drilling away smoothly when suddenly, the bit slams into a rock's hard edge like hitting an unexpected pothole. The sharp, localized impact can be brutal on carbide buttons, much like how hitting a curb can misalign your car's wheels. I've had moments where I could almost hear the crack as these buttons chip under stress due to stresses exceeding their material strength.

Table: Impact Factors on Carbide Buttons

| Factor | Description |

|---|---|

| Uneven Stress | Variability in resistance leading to uneven forces |

| Abrasive Surfaces | Sharp edges in fractured rocks increasing wear |

| Sudden Jolts | Unexpected changes in drilling conditions |

Abrasive Wear from Sharp Edges

Sharp edges in fractured rocks are like the villain in our drilling story. Every encounter with these harsh surfaces is a battle that risks chipping the buttons. If the rock contains hard minerals, the abrasion becomes even more intense. I've learned to respect these edges; they’re relentless adversaries that demand constant vigilance against abrasive interaction5.

Vibration and Harmonics

Drilling through fractured rocks can feel like being in a vibrating chair you can't switch off. The drill bit oscillates, bounces, and sometimes resonates with the rock's natural frequencies. This vibration isn't just annoying—it's a silent saboteur that wears down carbide buttons over time due to harmonic resonance.

Entrapment and Jamming Risks

Getting stuck is every driller's nightmare. When bits become lodged in fractures, freeing them feels like pulling a stuck boot from thick mud. The uneven forces required to free or continue drilling can chip carbide buttons faster than you'd expect. And don’t get me started on the debris wedged within fractures—it’s like trying to walk with pebbles in your shoe, causing constant abrasion that wears down the bit through additional abrasion6.

Carbide buttons experience uneven stress in fractured rocks.True

Fractured rocks cause irregular resistance, leading to uneven force on carbide buttons.

Vibrations in drilling do not affect carbide button wear.False

Vibrations from inconsistent rock composition can amplify wear on carbide buttons.

What Are the Risks of Entrapment and Jamming in Fractured Formations?

Have you ever found yourself stuck between a rock and a hard place? Drilling through fractured formations feels a lot like that, but on a much bigger scale.

Entrapment and jamming in fractured formations can wreak havoc on drilling operations. These issues lead to equipment wear, delays, and safety hazards due to unpredictable rock behaviors. Mitigation involves using specialized tools and techniques tailored for these challenging conditions.

Understanding Entrapment in Fractured Formations

Picture this: you're navigating a maze with hidden traps at every corner. That’s what it feels like maneuvering a drill bit through fractured formations. Once, I was working on a project where our drill bit got hopelessly caught in a void we hadn't anticipated. It was like trying to extract a splinter from a lion's paw—nerve-wracking and tricky. These zones are unpredictable, and even the most seasoned driller can find themselves entangled in nature's puzzles.

Key Factors Contributing to Entrapment:

- Crack and Void Presence: These sneaky little traps hide within the formations, ready to latch onto unsuspecting drill bits.

- Irregular Stress Distribution: Imagine walking on a tightrope where the tension changes with every step—that's the kind of uneven force we're dealing with here.

The Impact of Jamming on Drilling Operations

Jamming is like trying to drive through rush hour traffic with debris piling up around your tires. During one of my drilling adventures, the path became clogged with debris, halting our progress like a bad traffic jam. In fractured rocks, this is an all-too-common scenario.

| Risk Factors | Consequences |

|---|---|

| Debris Build-Up | Increased wear on drill components |

| Rock Abrasion | Potential damage to drill surfaces |

Mitigation Strategies:

- Utilizing advanced drilling technologies7 designed to clear debris efficiently.

- Implementing regular inspections to detect early signs of jamming.

Safety Hazards Associated with Entrapment and Jamming

Drilling in these environments is like playing a high-stakes game where the rules can change at any moment. I remember a sudden jolt that nearly knocked our entire crew off balance—it was a heart-stopping reminder of how quickly things can go awry. The key to safety is being prepared for anything.

- Sudden Jolts: These can lead to unexpected movements, risking both equipment and operator safety.

- Equipment Strain: The inconsistent forces can push equipment beyond its limits, leading to failures.

Preventative Measures8 are crucial. From using robust equipment that can handle the unexpected to enforcing strict safety protocols, preparation is everything.

By truly understanding the wild nature of fractured formations, we can better prepare and adapt our strategies, minimizing risks while maximizing success. It's all about staying one step ahead of nature's curveballs.

Drill bits often get stuck in fractured formations.True

Fractured formations have cracks and voids, increasing the risk of entrapment.

Jamming only occurs in non-fractured formations.False

Jamming is common in fractured rocks due to debris accumulation.

Why does increased abrasion cause drill bit chipping?

Ever wondered why drill bits seem to chip so easily when dealing with abrasive materials? Let's explore this frequent frustration.

Drill bit chipping occurs due to increased abrasion from hard or mineral-rich materials, causing rapid wear. This happens as bits interact with sharp, rough surfaces or rocks containing abrasive minerals, leading to damage.

Understanding Abrasion in Drilling

I remember the first time I faced the dreaded drill bit chipping. It was during a drilling project where we hit a particularly tough patch of rock. The moment the bit met those quartz-laden rocks, it was like watching a cheese grater in action—but on my expensive drill bit! Abrasion in drilling often stems from such encounters with hard or abrasive materials, rapidly wearing down the cutting edges.

Factors Contributing to Increased Abrasion

I’ve learned that understanding what makes a material abrasive can save me a lot of headaches (and expenses). Here’s a quick breakdown:

| Factor | Description |

|---|---|

| Operational Speed | Speeding through hard stuff? It’s a recipe for disaster. |

| Material Hardness | Harder materials lead to more rapid wear on drill bits. |

| Rock Composition | Rocks with high quartz or other abrasive minerals increase wear. |

Effects on Drill Bit Integrity

Every time I pushed a bit too hard or fast, it wasn’t just surface wear I dealt with; it was thermal and mechanical stress that took a toll:

- Surface Wear: Rough surfaces strip away protective coatings, exposing softer layers beneath.

- Thermal Stress: The heat from friction expands metals, sometimes leading to cracks.

- Mechanical Stress: High-speed impacts with hard surfaces? That’s how fractures happen.

These factors together spell doom for bits in harsh conditions.

Preventative Measures

I found relief by switching to bits tailored for abrasive environments—those with special coatings or tougher alloys. Maintaining the right speed and pressure also goes a long way in reducing wear.

For more about selecting the right drilling equipment9 for abrasive conditions, expert resources are invaluable.

Understanding Drill Bit Material

Choosing the right material can be the difference between constant headaches and smooth drilling:

- Tungsten Carbide: My go-to for its resilience in tough conditions.

- Diamond-Tipped Bits: They work wonders on extremely hard materials but come at a price.

For detailed comparisons of drill bit materials10, technical guides can provide the insights needed for each application.

Quartz content in rocks increases drill bit wear.True

Quartz is a hard mineral that accelerates abrasion on drill bits.

Diamond-tipped bits are unsuitable for hard materials.False

Diamond-tipped bits are ideal for cutting through hard materials.

How Do Vibrations and Harmonics Affect Drill Bit Wear?

Imagine your drill bit singing its way through rock, only for vibrations and harmonics to cut the melody short. These forces are unseen villains in drilling, stealthily accelerating wear and tear.

Vibrations and harmonics lead to oscillations in drill bits, amplifying stress and friction that accelerate wear, especially in components like carbide buttons. Managing these factors can significantly enhance drill bit longevity and performance.

Induced Vibrations in Drilling

I remember the first time I truly grasped how vibrations could wreak havoc on a drill bit. Picture this: you're drilling through layers of unpredictable rock formations, each one a different density and texture. It felt like playing a game of musical chairs with geology. These vibrations are born from mechanical imbalances or the shifting moods of the rock itself, causing the drill to dance more than drill. This dance can quickly turn destructive without proper dampening systems to cushion the chaos.

- Mechanical Imbalance: An uneven weight distribution on the bit can cause wobbling.

- Formation Variability: Different rock densities introduce inconsistent forces11 that can propagate as vibrations.

To manage these vibrations, operators often rely on dampening systems that minimize oscillation impacts12.

Harmonic Resonance Effects

There was this one project where we hit harmonic resonance. It was like the drill bit hit a nerve with the earth, causing it to shake uncontrollably. The resonance matched the natural frequencies of both the rocks and our equipment, making vibrations feel ten times stronger. The once smooth operation turned into a battle against time, as excessive wear threatened to retire our bits prematurely.

- Increased Wear: Resonance can heighten bit oscillation13, causing excessive friction and wear.

- Potential Damage: Continuous resonant vibration may result in structural failures within the drill bit or related equipment.

Proper tuning of drilling speeds and monitoring can mitigate resonance impacts by keeping an ear out for those telltale frequencies became our best allies.

Practical Mitigation Strategies

| Strategy | Description |

|---|---|

| Speed Adjustment | Altering rotational speed to avoid critical resonance frequencies. |

| Bit Design Innovations | Implementing designs that inherently reduce vibration transmission. |

| Active Monitoring Systems | Utilizing sensors to detect and adjust for excessive vibrations. |

These strategies have saved me countless hours of downtime and frustration, ensuring a balanced approach14 to vibration management, ultimately enhancing bit performance.

Impact on Drill Bit Components

The consequences of vibrations are most painfully felt in high-stress areas:

- Carbide Buttons: Repeated impacts from vibrations can chip or crack these elements, necessitating more frequent replacements.

- Body Structure: Vibrational stress can lead to fatigue and eventual fracturing over time.

Understanding these impacts helps me make smarter choices about materials and designs that stand up better against vibrational wear.

Mechanical imbalance causes drill bit wobbling.True

Uneven weight distribution on the bit leads to wobbling.

Harmonic resonance reduces drill bit wear.False

Resonance amplifies vibration effects, increasing wear.

Conclusion

Fractured rock formations increase chipping in DTH drill bits due to irregular stress, concentrated impacts, and abrasive interactions, leading to uneven wear and reduced tool lifespan.

-

Learn how fractured rock formations impact drill bits by causing uneven stress distribution, which affects wear patterns. ↩

-

Discover how sudden resistance changes during drilling increase stress on drill bits, affecting their longevity. ↩

-

Explore how torsional forces affect drill bits, leading to misalignment and increased wear rates. ↩

-

Understanding variable resistance helps optimize tool selection and improve operational efficiency in challenging geological conditions. ↩

-

Exploring abrasive wear effects helps identify strategies to enhance tool durability and performance. ↩

-

Learning about debris effects aids in selecting appropriate tools and techniques for minimizing wear. ↩

-

Highlights cutting-edge solutions that improve efficiency by preventing debris-related jamming. ↩

-

Provides guidelines and best practices to enhance safety during complex drilling operations. ↩

-

Gain insights on selecting durable drill bits for challenging conditions, enhancing operational efficiency. ↩

-

Understand which materials best resist abrasion to reduce wear and extend tool life. ↩

-

Learn about mechanical imbalance causes to improve drilling techniques and minimize vibration-related issues. ↩

-

Explore advanced dampening technologies that can reduce vibration effects during drilling operations. ↩

-

Understand the implications of harmonic resonance on equipment wear to enhance performance. ↩

-

Discover comprehensive strategies for managing vibrations to ensure optimal drill bit longevity. ↩