Have you ever thought about why some DTH drill bits cost more than others? Many elements affect these prices. Understanding them helps you choose better options for drilling projects.

Several critical factors influence the price of DTH drill bits. Material quality is one of these important factors. Manufacturing processes also play a very significant role. Bit size and type affect the price too. Brand reputation probably matters a lot. Technological innovations can change prices as well. Market conditions often sway pricing. Understanding these elements is crucial. You are better equipped to make informed purchasing decisions when you grasp these factors.

When I began in the drilling industry, I was shocked to discover the many things that affect the cost of DTH drill bits. The size or brand isn't everything. Material quality, design complexity and market demand are very important. For example, I once bought bits crafted from high-grade tungsten carbide. They cost more initially, but their durability saved money over time. Fewer replacements were needed. Understanding these elements is very helpful for choosing the right bit for your needs. It truly helps.

Material quality significantly affects DTH drill bit pricing.True

Higher quality materials lead to increased durability and performance, impacting the cost of DTH drill bits.

Brand reputation has no effect on DTH drill bit prices.False

A strong brand reputation often correlates with higher prices due to perceived quality and reliability in the market.

How Does Material Quality Affect the Pricing of DTH Drill Bits?

Have you ever thought about why some DTH drill bits are expensive? The world of materials is fascinating. Quality materials really change how well they work and how much they cost. Quality matters.

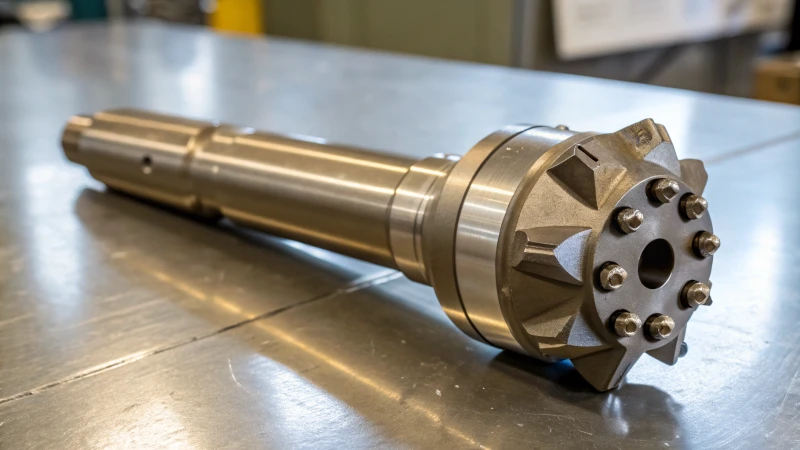

Material quality directly affects DTH drill bit pricing. Higher-grade materials like premium carbide and high-quality steel increase durability and performance. They justify their costs for long-term savings in drilling operations. High-quality materials really last longer.

Understanding Material Quality in DTH Drill Bits

Material quality plays a crucial role in determining the pricing of DTH drill bits. The composition of materials not only affects durability and performance but also impacts the overall cost of manufacturing. Let's explore some key factors:

1. Carbide Quality

The type and quality of tungsten carbide used in DTH drill bits significantly influence their price. High-grade carbide provides better wear resistance and longer life, making it more expensive.

For instance, while standard carbide may last through moderate drilling conditions, premium carbide options can withstand harsher environments, leading to reduced replacement costs over time.

| Carbide Type | Durability | Cost Implication |

|---|---|---|

| Standard Carbide | Moderate | Lower initial cost |

| Premium Carbide | High | Higher upfront cost |

2. Steel Grade

The steel used in the drill bit body also affects pricing. High-grade steel offers enhanced durability and resistance to wear and fatigue, which commands a higher price.

Investing in higher-grade steel can lead to significant savings in operational costs due to lower failure rates and reduced downtime.

3. Manufacturing Process Complexity

The complexity of the design and manufacturing process influences the price of DTH drill bits as well. More intricate designs often require advanced techniques and precision engineering, resulting in higher production costs.

Example:

- Basic Bit Design: Lower cost due to simpler manufacturing.

- Advanced Bit Design: Higher price reflects the complex engineering involved.

4. Size and Type of Bit

Larger drill bits require more materials and effort to produce, generally making them more expensive than smaller bits. Additionally, specialized bits designed for specific applications (like those with unique face designs) tend to carry a premium due to customization.

5. Brand Reputation

Well-known brands with established reputations for quality often charge more for their drill bits. This premium pricing reflects not just the product quality but also the value associated with warranties and customer support.

6. Technological Innovations

Drill bits that incorporate advanced features, such as enhanced flushing mechanisms or patented technologies, can be more costly due to the significant investment in R&D required to develop these innovations.

Summary of Influencing Factors

The table below summarizes how different material qualities impact DTH drill bit pricing:

| Factor | Impact on Pricing |

|---|---|

| Carbide Quality | Higher durability = higher cost |

| Steel Grade | Better performance = increased price |

| Manufacturing Complexity | Intricate designs = more expensive |

| Bit Size | Larger size = higher material cost |

| Brand Reputation | Established brands command premium pricing |

| Technological Innovations | Advanced features = additional costs |

Understanding these elements allows buyers in industries such as mining and construction to make informed decisions about their investments in DTH drill bits. By evaluating how material quality correlates with performance and durability, they can determine whether higher prices justify the benefits gained through enhanced efficiency and reduced operational risks.

For more insights on selecting the right materials for your drilling needs, explore our recommendations here1.

Higher-grade carbide increases DTH drill bit pricing.True

Premium carbide enhances durability, leading to higher manufacturing costs and prices for DTH drill bits.

Brand reputation does not affect DTH drill bit pricing.False

Established brands typically charge more due to perceived quality and customer support, impacting pricing significantly.

How Does the Manufacturing Process Affect Costs?

Some products cost a lot of money. Others are very affordable. The difference lies in the manufacturing process. Knowing this process really changes your business.

The manufacturing process affects costs. Factors include material quality, design complexity and production expenses. Brand reputation also plays a role. Technological innovations impact costs as well. Market dynamics are very influential. Understanding each element is crucial. This understanding helps optimize production efficiency. It also helps with determining product pricing.

The manufacturing process affects costs through several factors. Material quality, design complexity, production expenses, brand reputation, technological advances and market behaviors all play a role. Each factor is crucial in setting the final price of products. Let’s explore each one to understand how they affect your budget.

1. Material Quality and Composition

Material quality significantly shifts costs. High-quality materials like tungsten carbide and high-grade steel cost more initially. However, they offer improved wear resistance and longevity. I once sourced materials for a project and found that opting for better quality meant higher initial expenses. Yet the long-term benefits were clear.

Using standard tungsten carbide saved money initially. However, the higher wear rate led to more frequent replacements. Hence, investing in top-quality materials is wise in the long run as it saves costs over time.

Consider the following table illustrating the cost implications of varying material grades:

| Material Type | Quality Level | Cost Impact |

|---|---|---|

| Tungsten Carbide | Standard Grade | Lower Cost |

| Tungsten Carbide | High Grade | Higher Cost |

| Steel | Low Grade | Lower Cost |

| Steel | High Grade | Higher Cost |

For more info on material selection, see material quality considerations2.

2. Complexity of Design

Design complexity impacts costs directly. I remember a project needing precision-engineered drill bits. The complex design required advanced techniques, raising costs significantly.

Simple designs reduced manufacturing overhead, while intricate designs with specialized features increased expenses due to detailed engineering.

Additionally, specialized bits designed for unique geological conditions often require a custom approach, further increasing expenses.

To explore more about design intricacies and their impacts, check out design complexity in manufacturing3.

3. Production Costs

Production costs are vital in manufacturing and encompass a range of factors including labor, technology, and factory overhead.

These vary based on location and efficiency; I once worked where the factory's location inflated labor costs compared to rivals.

Consider factors like:

- Labor Costs: Skilled workers charge more but enhance production quality.

- Technology Investment: Automation lowers manual work but needs initial investment.

- Overhead Expenses: Utilities, rent and maintenance affect final costs.

Learn to manage production costs with tips at production cost optimization strategies4.

4. Brand and Manufacturer Reputation

Brand reputation greatly shapes manufacturing costs. Experienced buyers notice established brands charging more due to perceived value and reliability.

Key influencing factors include:

- Warranty and Support: Brands with extensive warranties often include these in prices.

- Market Positioning: Trusted brands keep high prices thanks to loyalty and trust.

This brand-cost relationship has been essential in my purchasing choices. Understand more about brand influence at impact of brand reputation on pricing5.

5. Technological Innovations

New technologies often involve high initial expenses but can be transformative; once we added advanced features to our drill bits which raised prices yet significantly improved performance.

My findings include:

- Enhanced Features: Improved efficiency through new tech means higher initial costs.

- Patented Technologies: Unique methods fetch premium prices due to distinctiveness.

Explore the advantages of technology in manufacturing at technological innovations in manufacturing6.

6. Market Dynamics

Market dynamics are beyond control but essential to consider; supply and demand greatly influence pricing as raw material shortages have caused costs to spike.Key factors include:

- Supply Chain Issues: Disruptions can cause unexpected price hikes.

- Economic Trends: Watching market trends helps forecast pricing changes.For a full view of market impacts on manufacturing, check market analysis for manufacturers7.

Higher quality materials increase manufacturing costs.True

Using high-grade materials like tungsten carbide raises production costs due to sourcing and processing complexities, impacting overall product pricing.

Complex designs reduce manufacturing expenses.False

Complex product designs require advanced techniques and skilled labor, leading to increased manufacturing costs rather than savings.

Why Are Larger or Specialized Drill Bits More Expensive?

Do you ever think about why big or special drill bits cost a lot? Let's explore the interesting world of drill bit prices. Discover why they might be expensive!

**Larger or special drill bits are very costly because of reasons like top-quality materials, complex production methods, bigger sizes, brand name, new technology and changing market trends. Knowing these reasons probably helps you understand why they are worth the money for your work. These facts may really help with understanding.

- Material Quality and Composition

The material of drill bits often affects their price. Larger or special drill bits use better materials than regular ones.

Carbide Quality꞉ Tungsten carbide in these bits is probably higher grade. It fights wear better and lasts longer. I used a high-grade carbide bit for a tough task. It really surprised me by performing well and saving replacement costs!

Steel Grade꞉ Steel in these bits might be superior. This increases toughness and wear resistance. Better material choices really change things when working in hard conditions. They do.

For more about material quality, check out material specifications.

- Manufacturing Process

The production process is also a reason for higher prices.

Complexity of Design꞉ Special drill bits have complex designs needing advanced methods. I saw the work behind creating a bit for a certain rock or drilling type. It’s not a simple task!

Production Costs꞉ Factors like labor, technology and overhead can vary by maker. This influences the final price. These all add to the cost of making special tools. Each does.

To learn about the making process, visit manufacturing techniques.

- Size and Configuration

Size is important for drill bits! Really important. Larger drill bits need more material and effort, increasing their price.

Size꞉ Larger drill bits use very much more material than small ones. I recall needing a big bit for a task. The weight surprised me. The cost surprised me even more.

Type and Configuration꞉ Special designs suited for certain drilling can be more expensive due to their custom nature. Knowing this really matters when buying these tools.

Explore drill bit sizes with our size comparison chart.

- Brand and Manufacturer Reputation

The brand name of the drill bit really influences its cost.

Brand Reputation꞉ Trusted brands with good quality reputation charge more. Through experience, I learned that paying a bit more totally pays off in performance and reliability.

Warranty and Support꞉ Higher costs may also include long warranties and very good customer support. I trust brands with solid support and it often affects my choice.

Discover more about brand pricing at brand value analysis.

- Technological Innovations

New technology really determines drill bit prices.

Advanced Features꞉ Drill bits with new technologies - like better flushing systems - are expensive because of research and development costs. A well-designed bit made a hard job much easier for me.

Patented Technologies꞉ Bits with unique technologies can be costly because of their efficiency. It’s always interesting to see what new features come up!

For details on technological changes, visit technology impacts.

- Market Factors

Market dynamics play a key role in pricing.

Supply and Demand꞉ Economic rules of supply and demand affect prices. High demand or low availability increases cost. I consider this when planning work.

Economic Conditions꞉ Broader economic factors, like changes in raw material prices, also impact drill bit prices. Watching these trends helps me buy wisely.

For market trends, check market dynamics.**

Main Content

I often wonder about this while in a hardware store. I stand there, looking at rows of drill bits. Each drill bit has a different price and use. Several factors help explain why larger or special drill bits cost more than standard ones. Let's explore this together, okay?

1. Material Quality and Composition

Larger or specialized drill bits are often made from higher quality materials compared to standard options. This includes:

-

Carbide Quality: The tungsten carbide used in these drill bits is often of a higher grade. This means better wear resistance and longer life expectancy, which justifies the increased cost.

-

Steel Grade: Similarly, the steel used for the body of these bits can be of superior grade, enhancing durability and wear resistance. Higher quality materials directly impact the price due to their enhanced performance in demanding conditions.

For more insights on material quality, check out material specifications8.

2. Manufacturing Process

The complexity involved in manufacturing larger or specialized drill bits also contributes to their higher price.

-

Complexity of Design: Specialized drill bits may have intricate designs that require advanced manufacturing techniques, which can increase production costs.

-

Production Costs: Factors such as labor costs, technology utilization, and factory overhead can vary significantly by manufacturer, impacting the final price of the drill bits.

To understand more about manufacturing processes, visit manufacturing techniques9.

3. Size and Configuration

Larger drill bits naturally require more material and effort to manufacture, leading to a direct increase in price.

-

Size: The material used in larger drill bits is more significant compared to smaller ones, making them inherently more expensive.

-

Type and Configuration: Specialized configurations designed for specific drilling conditions or rock types can also come at a premium price due to their customized nature.

Explore various bit sizes in our size comparison chart10.

| Bit Type | Typical Size Range | Specialization Level | Price Range |

|---|---|---|---|

| Standard Bits | 1-6 inches | Low | $10 - $50 |

| Large Bits | 7-12 inches | Medium | $50 - $150 |

| Specialized Bits | 12+ inches | High | $150 - $500 |

4. Brand and Manufacturer Reputation

The brand associated with the drill bit plays a crucial role in its pricing.

-

Brand Reputation: Established brands known for quality and reliability often charge higher prices. Their reputation provides assurance of product performance and reliability.

-

Warranty and Support: Higher prices can also reflect the value added through extensive warranties and customer support services offered by reputable manufacturers.

Learn more about brand impacts on pricing at brand value analysis11.

5. Technological Innovations

Technological advancements are a significant factor in the pricing of drill bits.

-

Advanced Features: Drill bits that incorporate innovative technologies, such as enhanced flushing mechanisms or specialized cutting structures, often carry a higher price tag due to R&D investments.

-

Patented Technologies: Bits utilizing proprietary technologies can also command a premium due to their uniqueness and effectiveness in challenging applications.

For further details on technological advancements, visit technology impacts12.

6. Market Factors

Lastly, market dynamics play a significant role in pricing.

-

Supply and Demand: The basic principles of supply and demand can affect the prices of larger or specialized drill bits. Limited availability or high demand can lead to increased prices.

-

Economic Conditions: Broader economic factors, including fluctuations in raw material costs, tariffs, and currency exchange rates, can also influence the overall cost of drill bits.

to keep updated on market trends, check out market dynamics.

Larger drill bits require more material to manufacture.True

The size of larger drill bits necessitates the use of more raw materials, increasing production costs.

Specialized drill bits are always cheaper than standard ones.False

Specialized drill bits often come at a premium due to their unique designs and materials, contradicting this claim.

How Does Brand Reputation Influence Pricing Strategies?

Some brands charge high prices, while others struggle to sell cheaply. Brand reputation explains this difference. This concept shapes how companies set prices. People often overlook this influence.

Brand reputation very much influences pricing strategies. Businesses with good reputations charge higher prices. They succeed because of consumer trust and loyalty. Customers believe in the quality they perceive. This link between brand image and pricing is crucial for profit. Profits depend on this connection.

Understanding Brand Reputation

Brand reputation highlights how customers feel about a company. This perception is shaped by experiences, marketing, and customer feedback. A strong brand reputation can significantly impact pricing strategies. Brands that are perceived as high-quality can often command higher prices due to consumer trust.

For instance, I needed a new drill bit and had to choose between a famous brand and a lesser-known one. Both had similar features, but I chose Eazydrill because friends and colleagues praised it highly. Their trust, built over time with positive experiences, influenced my choice.

The Psychological Aspect of Pricing

Psychology plays a big role in buying decisions. Research shows that consumers often associate higher prices with better quality. This means that companies with strong reputations can charge more without losing customers.

Consider the table below that illustrates how brand reputation correlates with perceived value:

| Brand Reputation Level | Pricing Strategy | Consumer Perception |

|---|---|---|

| High | Premium Pricing | High Quality |

| Moderate | Competitive Pricing | Average Quality |

| Low | Discount Pricing | Low Quality |

I once bought a slightly more expensive hammer from a well-known company. I believed it would be more durable and indeed, it lasted longer. Companies with good reputations often set higher prices. Loyal customers do not stop buying from them.

Customer Loyalty and Retention

A good brand reputation creates loyalty. Eazydrill's consistent quality keeps me returning for more. Even with higher prices, I value their dependable products. Customer loyalty is priceless; loyal buyers return and accept higher prices while staying happy with their purchase.

Brand Reputation in Competitive Markets

In competitive markets, brand reputation serves as a hidden advantage to allow higher prices. Companies may utilize their reputation as a competitive advantage to maintain margins while ensuring customer satisfaction.

In fields like drilling equipment, where functionality and durability are critical, investing in brand reputation really benefits companies a lot. Explore more on market strategies13.

The Role of Online Reviews and Ratings

Online reviews are crucial today; checking reviews before buying is now second nature to many consumers. Positive reviews improve a brand's image, enabling higher prices while negative reviews do the opposite.

Understanding how to manage online presence effectively can lead to improved sales performance. Encouraging happy customers to leave glowing reviews or addressing negative ones really matters in this digital age.

Conclusion on Brand Reputation Impact

Reflecting on brand reputation and pricing shows clear connections: quality, customer experiences, and online feedback shape pricing strategies across many industries. Understanding how consumer behaviors interact with brand positioning is key for successful companies in competitive markets.

Strong brand reputation allows for premium pricing.True

Brands with a solid reputation can charge higher prices due to consumer trust and perceived quality.

Negative reviews do not impact a brand's pricing strategy.False

Negative reviews can harm a brand's reputation, leading to lower prices to attract customers.

How Do Technological Innovations Influence Drill Bit Costs?

I often wonder how technological changes impact drill bit prices. The world of drill bits evolves constantly. Let's explore this fascinating question together.

Technological innovations impact drill bit prices. New materials like tungsten carbide are important. Modern methods like CNC machining and 3D printing also play a role. Custom tools for special uses are another factor. Patented technologies influence costs too. Economic aspects affect supply and demand. Comprehending these elements is crucial. It is very important for strategic buying choices.

The Role of Material Innovations

Materials' quality always jumps to mind when I think about drill bits. It is fascinating to notice how new materials, like high-performance tungsten carbide, truly change things. Once, we changed to these bits in a project. The wear resistance and longevity were impressive. Yes, they have a higher price initially. However, buying fewer replacements really saved money.

| Material Comparison Table: | Material Type | Durability | Cost Impact |

|---|---|---|---|

| Standard Steel | Moderate | Low | |

| High-Grade Steel | High | Medium | |

| Tungsten Carbide | Very High | High |

Investing in better materials often pays off over time. This changes our buying choices significantly.

Advanced Manufacturing Techniques

The evolution of manufacturing processes really amazes me. Have you ever seen a CNC machine in action? It offers precise engineering that allows complex designs. These designs improve performance. I recall a factory using 3D printing; it greatly reduced material waste. Despite the higher costs, long-term benefits were obvious to me.

- Precision Engineering: Utilizing CNC (Computer Numerical Control) machining allows for intricate designs that enhance performance but at a higher production cost.

- 3D Printing: This emerging technology is allowing manufacturers to produce complex designs at reduced material waste, potentially lowering costs in the long run.

As a result, drill bits produced with these advanced methods often come with a premium price tag due to the R&D costs involved in their development.

Specialized Designs and Customization

Customized solutions are something I truly value. I remember a project needing special drill bits for unique geological formations. The R&D work raised production costs; however, the results were absolutely worth it. Seeing how innovative features, like advanced cooling or special cutting shapes improved efficiency was thrilling.

- Customized Drill Bits: Tailored for particular geological formations can significantly increase production costs due to the required R&D and material specificity.

- Innovative Features: Bits that incorporate features such as advanced cooling systems or specialized cutting geometries tend to be more expensive.

These features could lower future operational costs while influencing buyers' decisions on investment.

Patented Technologies and Market Exclusivity

Patented technologies usually have a high price. I have watched how brands investing a lot in R&D can create unique drill bits that stand out in the market. These brands charge more for their special offerings because it's not just about beating others; it's about giving something really valuable that stands out in the market.

Economic Factors Driven by Innovation

Technological changes affect the market in surprising ways:

- Supply and Demand: New technologies can create demand spikes for specific drill bits, driving prices up.

- Economic Conditions: Fluctuating raw material prices influenced by technological advancements affect overall production costs.

For example, when demand rises for a certain drill bit due to new technology, prices can increase; sometimes new materials decrease our use of old resources which might lower final prices and change market dynamics greatly.

In conclusion, my exploration of how technological innovations affect drill bit costs has revealed a complex array of factors. Learning these connections helps me make smarter buying choices and feel ready to predict future trends in drilling technology. It's a very exciting time to be in this industry!

High-performance tungsten carbide increases drill bit costs.True

Tungsten carbide's durability justifies its higher price due to reduced replacement frequency, influencing overall drill bit costs.

3D printing reduces all drill bit manufacturing costs significantly.False

While 3D printing lowers material waste, it may not reduce all manufacturing costs due to R&D expenses involved.

What Market Factors Should You Consider When Purchasing DTH Drill Bits?

Exploring the world of DTH drill bits might feel daunting. I understand the importance of grasping the market factors that impact your investment. These elements are truly important. Let us discover what truly matters.

When buying DTH drill bits, think about the material quality. Pay attention to manufacturing processes. Size and type are important. Look at brand reputation. Check for technological innovations. Economic conditions influence pricing.

Understanding Material Quality and Composition

When I began buying DTH drill bits, I quickly discovered that choosing wisely involves more than just picking the first option. Each factor is crucial. It’s not just buying a product; it’s an investment in work and efficiency.

Material quality really matters. High-grade tungsten carbide bits are exceptional. I tried cheaper bits once to save money. The higher wear rate soon turned savings into costs. This is very important. Top-quality materials reduce replacements and downtime. This, in busy places, is really helpful. I often compare materials to choose wisely.

| Material Type | Benefits | Cost Impact |

|---|---|---|

| Tungsten Carbide | High wear resistance, longer life | Higher initial cost |

| Steel Grade | Enhanced durability | Moderate cost impact |

Investing in high-quality materials can lead to lower replacement rates and increased efficiency in drilling operations, making them cost-effective in the long run. Explore material comparisons14 to make informed choices.

Evaluating Manufacturing Processes

Now, let’s discuss manufacturing processes. Complex designs can increase prices a lot. Advanced techniques often lead to better performance. It feels like upgrading your tools. Everything works smoother!

- Complexity of Design: Detailed designs improve performance but cost more.

- Production Costs: Regional differences in labor and technology affect the final price.

Understanding these details helps decide if extra costs bring enough benefits. For more details, I often explore manufacturing insights15.

Assessing Size and Type

The size and type of drill bit also matter. I once misjudged the size needed for a project.

| Bit Size | Typical Price Range | Considerations |

|---|---|---|

| Small (2-4" diameter) | $100 - $300 | General applications |

| Medium (4-6" diameter) | $300 - $700 | Versatile usage |

| Large (6+" diameter) | $700 - $1,500 | Specialized drilling tasks |

Larger bits cost more due to materials and production complexity. I always check bit size specifications to match project needs. This is vital.

Brand and Manufacturer Reputation

Brand reputation influences my choices. A popular brand means reliability and performance, often with higher costs.

Here are factors to consider:

- Warranty and Support: Brands with long warranties offer peace of mind.

- Customer Reviews: Reading feedback has helped me avoid many poor choices.

Explore reviews on top-rated manufacturers16 to make informed decisions.

Technological Innovations in Drill Bits

Modern innovations in drill bits can improve efficiency a lot. These bits might be pricier; yet, benefits often justify the cost.

- Advanced Features: Special cutting or flushing mechanisms enhance performance.

- Patented Technologies: Innovations can elevate work but may raise costs due to R&D investments.

Stay updated on latest innovations to ensure you choose the best technology for your needs.

Economic Factors Influencing Prices

Finally, we can’t ignore broader economic factors that influence pricing of DTH drill bits:

- Supply and Demand Dynamics: Prices increase when supply is low and demand is high.

- Raw Material Costs: Changes in costs for raw materials like steel impact prices.

I keep an eye on economic trends17 to anticipate potential price changes.

High-grade tungsten carbide bits last longer than steel grade bits.True

Tungsten carbide offers superior wear resistance, making it more durable and cost-effective over time compared to steel grade drill bits.

Manufacturing complexity does not affect DTH drill bit prices.False

More complex manufacturing processes typically lead to higher production costs, impacting the final price of DTH drill bits significantly.

Conclusion

DTH drill bit prices are affected by material quality, manufacturing processes, size and type, brand reputation, technological advancements, and market conditions.

-

Learn how material choices impact drill bit performance and costs, aiding your purchasing decisions. ↩

-

Clicking this link will provide valuable insights into optimizing manufacturing expenses through effective strategies. ↩

-

This link will offer detailed information on managing production costs effectively, essential for any manufacturing business. ↩

-

Explore this link to understand various factors influencing production costs that can help streamline operations. ↩

-

Gain insights from this link regarding how brand reputation can influence pricing strategies within manufacturing. ↩

-

This link discusses the long-term benefits of investing in technological innovations for cost savings in manufacturing. ↩

-

Understanding market dynamics is vital; this link provides useful resources on economic factors affecting production costs. ↩

-

Discover the detailed reasons behind the pricing of larger drill bits and how they compare to standard ones. ↩

-

Learn about the materials and technologies used in expensive drill bits that justify their costs. ↩

-

Get insights into how manufacturing processes affect drill bit prices and what to look for. ↩

-

Understand how brand reputation influences pricing for drilling equipment and what it means for your purchases. ↩

-

Stay informed about market trends affecting drill bit prices and strategies for cost-effective purchasing. ↩

-

Understanding how brand reputation affects pricing will enhance your marketing strategies and improve profitability. ↩

-

Understanding these factors will empower you to make more informed purchasing decisions, optimizing both performance and costs. ↩

-

This link will provide insights on how technological advancements impact the efficiency of drilling operations. ↩

-

This resource will outline how brand reputation influences product pricing in the drilling equipment market. ↩

-

Stay ahead of market trends by understanding the economic factors that affect drilling equipment pricing. ↩