Have you ever stood before a pile of drilling tools, wondering which one saves both time and money?

Valved DTH hammers possess a complex valve system. This system controls airflow but increases air consumption. The design is intricate. In contrast, valveless DTH hammers enjoy a simple structure. They have fewer parts. This simplicity really improves efficiency. Air consumption is lower. Valveless hammers are ideal for drilling hard rocks. They perform very well in such conditions.

When I first started exploring DTH hammers, it felt like diving into a technical sea. The language was confusing. But once I held both valved and valveless types, differences became clearer. Valved hammers reminded me of an old car I owned. They were solid but needed more care and energy. Valveless hammers felt like a sleek, efficient car that moves easily on rough roads. I learned that choosing the right hammer depends on your drilling needs. Some people prioritize easy maintenance. Others care more about fast drilling. Understanding these tools helps choose the best one for your project.

Valved DTH hammers consume more air than valveless ones.True

Valved hammers have complex mechanisms leading to higher air consumption.

Valveless DTH hammers are less efficient in hard rock drilling.False

Valveless hammers are more efficient due to simpler design and lower air use.

How Does the Design of Valved and Valveless DTH Hammers Affect Performance?

Ever wondered why some drilling hammers excel more than others? The design plays a big role. Valved and valveless DTH hammers differ in this design.

Valved DTH hammers often cause slower drilling. Their complex valve systems really increase energy consumption. Valveless hammers have simpler designs. They provide faster drilling. Energy efficiency is usually better with them.

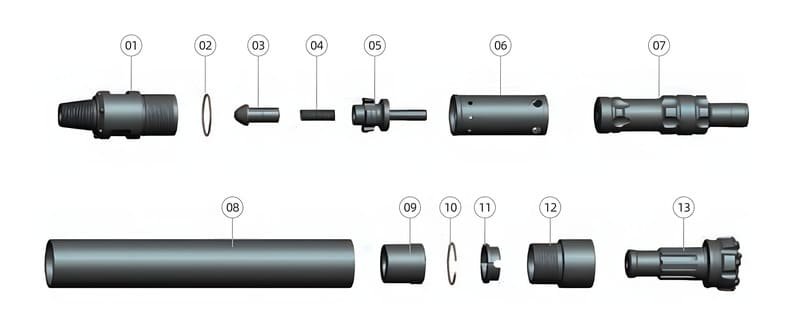

Design and Structural Differences

I remember my first experience with DTH hammers' technical details. It felt like solving a mystery novel! Valved hammers remind me of complex novels with intricate plots. They have a valve mechanism that controls airflow, which is fascinating yet may need more maintenance due to extra moving parts. On the other side, valveless designs1 are simple, similar to an engaging book. They use air distribution systems that simplify tasks.

Operational Efficiency

Simplicity often wins in operational efficiency. Valved hammers remind me of my old car; they need more air during the exhaust phase, slowing the process and increasing air use. Valveless hammers are like hybrid cars; they use air effectively, increasing impact frequency while using less air economically. They are likely better for air savings.

| Hammer Type | Energy Efficiency | Drilling Speed | Maintenance Complexity |

|---|---|---|---|

| Valved | Lower | Slower | Higher |

| Valveless | Higher | Faster | Lower |

Maintenance and Reliability

I have done many DIY repairs at home. Fewer parts often mean less trouble. Valved hammers are complex with more parts, similar to fixing a clock. In contrast, valveless hammers2 are like IKEA furniture; they have simpler structures, offering more reliability and fewer breakdowns. Simplicity leads to reliability.

Air Consumption Impact

High utility bills are frustrating! Valved hammers use more air, like leaving all your lights on. Valveless models can reduce air consumption by up to 30%. This is wonderful if you want to save costs—it feels like realizing you've been overpaying your energy bills! Choosing between these hammers often depends on balancing simple maintenance and efficiency of valveless models with any unique benefits valved hammers offer in special cases.

Valved hammers have higher maintenance complexity.True

Valved hammers involve more moving parts, increasing maintenance needs.

Valveless hammers consume more air than valved ones.False

Valveless hammers use up to 30% less air, enhancing efficiency.

How do valved and valveless DTH hammers differ in energy efficiency?

I first faced a decision between valved and valveless DTH hammers. I was amazed by how their energy efficiency could really influence the success of a drilling project.

Valved DTH hammers frequently waste energy because of their valve systems. Valveless hammers use air really well. They cut energy use by about 30%. These valveless hammers work with greater efficiency.

Design and Operational Principles

I began examining how these hammers work inside. Valved DTH hammers depend on a valve to control air flow. It resembles a tricky dance partner who occasionally misses a beat, causing small energy losses. In comparison, valveless hammers remind me of an efficient athlete. Their streamlined air system helps use every bit of energy effectively.

Valved DTH hammers incorporate a valve that regulates the flow of compressed air. This design introduces complexity but aims for precise control of air distribution. However, during operation, the valve system can cause energy losses. In contrast, valveless DTH hammers leverage a simpler air distribution mechanism on the cylinder wall, enhancing air utilization3 and resulting in higher energy efficiency.

Energy Consumption Analysis

I compared their energy use for the first time. The results were very clear. Valveless hammers are like an eco-friendly car - smart and efficient. They reduce energy use by a significant 30%. These savings are real during long drilling projects and lead to cost reductions.

The efficiency disparity is most evident in their energy consumption patterns:

| Hammer Type | Energy Consumption | Operational Efficiency |

|---|---|---|

| Valved | Higher | Lower |

| Valveless | Lower | Higher |

Valveless models offer a significant advantage in fuel consumption4, thereby reducing operational expenses for industries heavily reliant on drilling operations.

Performance Metrics

Valveless hammers perform like sprinting champions in drilling. They use impact energy efficiently and work faster. I witnessed them cutting through hard rock with ease.

- Impact Frequency: Valveless hammers truly shine, significantly increasing drilling speeds by up to 30% compared to their valved counterparts.

- Maintenance Needs: Their simple design demands less upkeep, providing peace of mind with fewer moving parts requiring less maintenance and boasting longer service life.

For industries focusing on minimizing downtime and maximizing throughput, valveless systems5 present a compelling choice.

Air Consumption and Environmental Impact

Valved hammers consume more air due to their complicated valve systems—picture them as gas-guzzlers in the drilling world. Valveless hammers use air wisely:

- This choice lowers costs and reduces environmental impact.

- Sustainability is very important today; these features matter more and more as industries strive for sustainable practices.

In evaluating these technologies, consider how each hammer aligns with specific project needs, operational environments, and long-term sustainability goals.

Valveless hammers reduce energy use by 30%.True

Valveless hammers utilize air better, cutting energy use by up to 30%.

Valved hammers have higher operational efficiency.False

Valved hammers have lower efficiency due to complex air regulation.

What Makes a Valveless DTH Hammer Faster in Drilling?

Have you ever worked on a drilling project and questioned why certain hammers simply do a better job than others?

Valveless DTH hammers often provide faster drilling speeds. Their simple design leads to efficient air use. This means they hit harder and waste less energy. Many people choose them for quick drilling jobs. They really are efficient.

Understanding DTH Hammer Types

When I started drilling, the options really confused me. Choosing between valved and valveless hammers was one of the toughest tasks. Here's what I found out:

Valved DTH Hammers

- Design: These hammers use a valve system to control air flow. This setup is complicated.

- Operation: Energy is lost due to pressure changes needed by the valves.

- Performance: They generally drill more slowly because of these energy losses.

Valveless DTH Hammers

- Design: They have a simpler air system. They're valve-free.

- Operation: They use compressed air very efficiently, reducing energy consumption by about 30%.

- Performance: Drilling with them is faster, with speeds approximately 15% to 30% quicker than valved hammers.

Impact on Drilling Speed

The straightforward design of valveless6 hammers speeds up work. With fewer parts, they are also more reliable. Their higher impact frequency really helps them cut through rock faster.

| Hammer Type | Air Consumption | Drilling Speed | Complexity |

|---|---|---|---|

| Valved | Higher | Slower | More |

| Valveless | Lower | Faster | Less |

Factors Influencing Choice

- Energy Efficiency: Valveless hammers perform superbly due to their low energy needs.

- Maintenance: Fewer parts mean easier upkeep; maintenance is quite simple for valveless designs.

- Application Suitability: They're ideal for hard rock, perfect for mining and construction projects.

- Cost Considerations: Initial costs are similar, but long-term savings with valveless hammers are significant.

When I choose a DTH hammer, I consider my project's needs. The environment and speed7 needed guide my choice. Usually, valveless hammers are best for tough jobs. Selecting the right hammer is important, just like choosing the right tool for any task.

Valveless hammers use 30% less energy than valved ones.True

Valveless hammers efficiently utilize compressed air, reducing energy consumption.

Valved hammers offer faster drilling speeds than valveless ones.False

Valveless hammers have faster drilling speeds due to efficient air use.

What are the maintenance differences between valved and valveless DTH hammers?

Understanding your equipment is crucial for drilling. This knowledge probably saves both time and money.

Valved DTH hammers need more care because of their complicated design. Valveless hammers are simpler. This eases maintenance. They probably last longer.

Maintenance Complexity: Valved vs. Valveless

In my early drilling days, I struggled with valved DTH hammers. They felt like puzzles full of moving parts. These hammers use a valve to control air, like fixing a leaky faucet. I regularly inspected them because the valve plates wore out often. Frequent checks and replacements were necessary.

Switching to valveless DTH hammers was refreshing. These hammers had fewer parts, making maintenance easier. Less complexity meant less chance of failure, which reduced downtime and maintenance costs. It was like choosing between an old car and a new one - both interesting, but one needed less care.

| Feature | Valved DTH Hammer | Valveless DTH Hammer |

|---|---|---|

| Components | More moving parts | Fewer components |

| Maintenance | More frequent | Less frequent |

| Downtime | Higher potential | Lower potential |

Inspecting Wear and Tear

With valved hammers, I concentrated on the valve plates. Any heavy wear indicated air flow problems. It felt like treating a cold early before it worsens.

For valveless hammers, I focused on the piston and cylinder8. Checking for scratches or damage there was very important to keep things running smoothly.

Parts Replacement Frequency

Maintaining valved systems was like a Jenga game. Each piece relied on another, making replacements tricky and expensive if not done carefully.

Valveless systems were simpler. I mainly focused on the piston, which made managing the supply chain9 easier.

Best Practices for Maintenance

- Lubrication: Sticking to a regular lubrication routine helped reduce wear.

- Inspection Schedule: I set up an inspection timetable based on each site's needs, especially in busy places.

- Training: Good training for my team was crucial to avoid errors that might cause unexpected failures.

Choosing between valved and valveless10 systems involves more than technical details. It's about understanding their impact on maintenance strategies, costs, and equipment lifespan. Knowing these differences greatly influenced our drilling operations and shaped every decision made.

Valved DTH hammers require more frequent maintenance.True

Valved hammers have complex designs needing regular inspections.

Valveless DTH hammers have higher downtime potential.False

Valveless hammers have fewer parts, reducing failure chances.

When Should You Choose a Valved Over a Valveless DTH Hammer?

Choosing between valved and valveless DTH hammers may feel like picking between two ice cream flavors. Both options are excellent. One might suit your needs right now.

Pick a valved DTH hammer for precise air control. This is important in complex geological formations. Controlled airflow becomes crucial in such environments. Valved hammers adapt to difficult drilling conditions. Their adaptability makes them very essential. They might not be the best for saving energy, though.

Understanding the Operational Context

I recall the first time I had to choose between a valved and a valveless DTH hammer. It felt like school again, choosing between two fun science projects. Valved hammers drew me in with their ability to control air precisely. They are the best choice for complex geological structures where exact airflow control is necessary.

Comparing Performance Metrics

| Feature | Valved DTH Hammer | Valveless DTH Hammer |

|---|---|---|

| Air Regulation | Controlled via valve mechanism | Direct, without a valve |

| Energy Efficiency | Moderate, with potential for air loss | High, better utilization of compressed air |

| Drilling Speed | Slower due to energy loss | Faster, with less energy loss |

I've seen valveless hammers praised for speed and efficiency in past projects. Yet, when more control was needed—like with random rock formations—valved hammers excelled. They provided great precision at crucial times. Precision was their key strength.

Maintenance and Reliability Considerations

Valved DTH hammers have a charm due to their complexity. They require more upkeep because of intricate parts like valves and regulators. This complexity allows tuning tailored to specific needs. In contrast, the simpler design of valveless hammers11 often means fewer points of failure and reduced maintenance.

Air Consumption Factors

Valved hammers act like a friend who always orders extra toppings; they use more air because of valve inefficiencies. This allows for fine-tuning performance to match specific needs. In places where air regulation12 is very important, their flexibility becomes crucial.

Choosing Based on Geological Conditions

Imagine facing tough or changing geological conditions. The precision of a valved hammer is invaluable here. Quick adjustments manage shifting rock formations effectively. This ability to adapt makes them favorites among mining companies and construction firms facing such challenges.

Ultimately, knowing when to select a valved DTH hammer involves evaluating these aspects against needs. Matching the choice with project needs ensures optimal performance and resource use.

For further insights on how these hammers can impact your operations, exploring case studies or expert analyses is recommended.

Valved hammers are more energy efficient than valveless ones.False

Valveless hammers are more energy efficient due to better air utilization.

Valveless hammers require less maintenance than valved ones.True

Valveless hammers have fewer components, reducing maintenance needs.

Conclusion

Valved and valveless DTH hammers differ in design, efficiency, and maintenance. Valveless hammers are simpler, more efficient, and faster, while valved hammers offer precise air control for complex drilling.

-

Explore further details about how design choices impact operational efficiency and maintenance needs. ↩

-

Learn why valveless hammers may provide better reliability and lower maintenance demands. ↩

-

Understanding the air distribution mechanism of valveless hammers can illustrate why they are more energy-efficient. ↩

-

Reduced fuel consumption leads to cost savings and environmental benefits, important factors for operational efficiency. ↩

-

Exploring these advantages helps highlight why industries might prefer valveless over valved systems. ↩

-

Understanding the mechanics behind valveless designs reveals their efficiency benefits. ↩

-

Exploring suitable hammer types for mining can ensure optimal equipment selection. ↩

-

Learn about common issues and maintenance tips for pistons and cylinders to enhance hammer efficiency. ↩

-

Discover strategies to streamline your inventory of critical spare parts for DTH hammers. ↩

-

Understand the benefits of each hammer type to better align with your drilling needs. ↩

-

Discover why many choose valveless hammers for efficiency and lower maintenance. ↩

-

Learn how air regulation impacts drilling efficiency and tool performance. ↩